Matsuya Foods Enhances Compliance Operations with RoboRobo Technology

Matsuya Foods Enhances Compliance Operations with RoboRobo Technology

Matsuya Foods Holdings, a prominent player in Japan's dining sector known for its gyudon (beef rice bowls) and various other food brands, has made significant strides in enforcing compliance checks across its operations. In collaboration with Open Corporation, which provides a compliance check service called RoboRobo, the company has successfully standardized its compliance verification processes across different departments, leading to improved efficiency, quality, and reduced operational burdens.

The Need for Enhanced Compliance Checks

Operating within a dynamic industry, Matsuya Foods interacts with numerous suppliers and service providers, hence their business is heavily reliant on stringent compliance checks. Recently, there has been an increasing emphasis on corporate social responsibility (CSR), making it necessary for businesses to diligently vet their partners—and not just new ones. This has led to an increase in internal workloads for compliance checks, causing inefficiencies due to varying processes used by different departments.

Moreover, the quality of checks was inconsistent, with subjective judgments leading to varying results. Employees were often overwhelmed by the responsibility—after all, a misjudgment could potentially lead to serious repercussions. This situation called for a transformative solution, guiding the company to seek an all-encompassing compliance tool to streamline its processes.

Enter RoboRobo: A Smart Solution

The quest for a suitable compliance tool ended with RoboRobo. With a proven track record in the food services sector and a good balance between ease of use and cost, RoboRobo was chosen as Matsuya’s compliance solution. The user-friendly interface meant that transitioning from varied departmental processes to a centralized system would be seamless, minimizing additional burdens on staff.

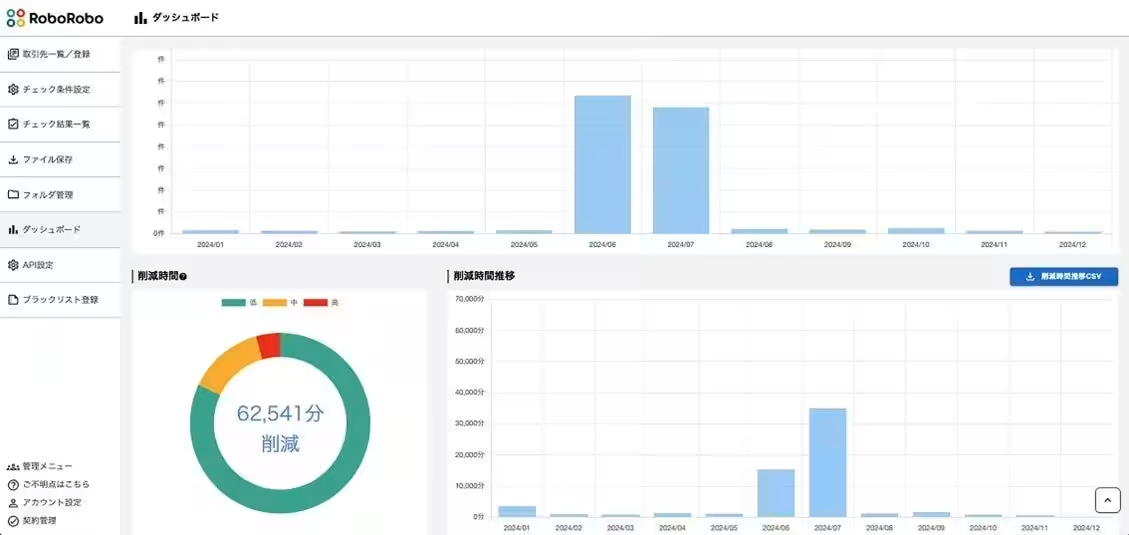

Various departments received training on the importance of compliance checks and introduced new procedures as they rolled out the tool. By early 2024, Matsuya Foods began utilizing RoboRobo effectively, leading to notable improvements across key areas.

Tangible Benefits Realized from the RoboRobo Integration

Over a year since the introduction of RoboRobo, Matsuya Foods has witnessed four major advancements:

1. Significant Reduction in Processing Time

The time taken for each compliance check has dramatically decreased from 5-6 minutes to just 1-2 minutes. This efficiency has led to a reported average saving of 87 hours of operations monthly for key staff members involved in compliance checks—an impressive jump in productivity.

2. Enhanced Visibility of Compliance Checks

Previously, individual departments conducted checks without a clear overview of the corporation’s compliance status. With RoboRobo’s centralized management approach, there’s now a clear record of when and who was checked. The ability to export results in Excel or CSV format also facilitates swift responses to audit inquiries, improving overall operational transparency.

3. Standardization of Check Quality

RoboRobo classifies risks into three clear categories: high, medium, and low, effectively eliminating inconsistencies that stemmed from individual judgment. This standardization ensures that every partner undergoes a reliable compliance check that meets Matsuya Foods’ expectations.

4. Reduced Stress for Department Staff

Previously, compliance officers carried heavy responsibilities, and the potential for critical errors added to their stress. With the introduction of RoboRobo, staff only need to submit minimal information about vendors. The centralized compliance department handles the ensuing tasks, allowing employees to direct their energy toward primary responsibilities. Many departments have reported being able to receive results on the same day—significantly enhancing their productivity.

Automation and Focus on Core Operations

While the operational departments have greatly benefited from using RoboRobo, the corporate compliance team has also undergone substantial changes. The process now involves three simple steps: receiving requests via an established electronic system, utilizing RoboRobo for checks, and returning the results electronically. Automation, here, plays a pivotal role in reducing manual workloads.

No longer burdened by subjective judgments, staff can now focus on high-risk cases, further lessening their mental load. Additionally, they can now dedicate adequate time to essential tasks like legal consultations and contract reviews, further enhancing operational effectiveness.

Open Corporation, through its RoboRobo lineup, aims to contribute to improved efficiency and business automation. By leveraging generative AI for automated summaries and LLM analysis for risk decisions, they provide staff with a conducive environment for effective decision-making. Continuing to mitigate legal risks and foster reliability, they remain committed to supporting their clients' sustainable growth.

For more information on RoboRobo Compliance Checks, visit their service page here.

Company Information

Open Corporation

Headquarters: 3-3-1 Nishishimbashi, Minato, Tokyo

Established: July 2013

President: Takehisa Ishii

Capital: 300 million yen

Business: Information processing services using smart robots (RPA, AI), consulting services, outsourcing, digital marketing, online advertising.

Matsuya Foods Holdings

Headquarters: 1-14-5 Nakacho, Musashino, Tokyo

Founded: June 1966

Established: January 16, 1980

President: Kazumichi Kaburaki

Capital: 6.65593 billion yen

Business: Management of group companies with a focus on the dining industry.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.