NEC Nexsolutions Enhances Factory DX for Kato Model Train Production

NEC Nexsolutions Transforms Kato Model Train Production

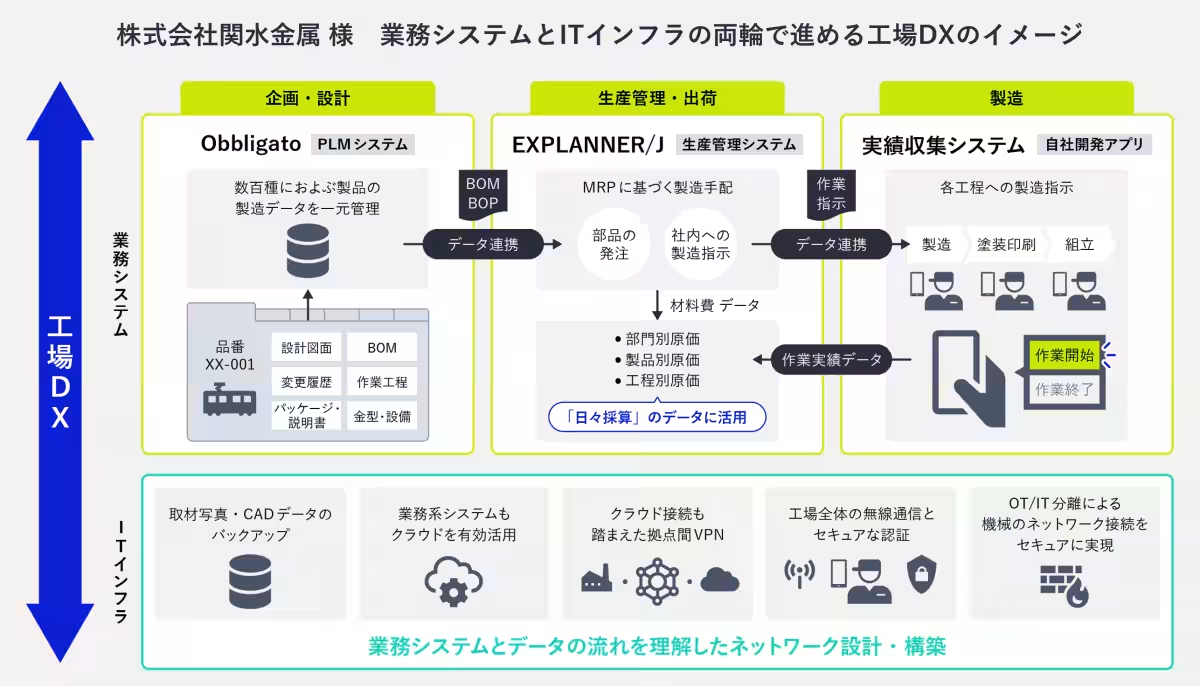

In a significant move to enhance operational efficiency, NEC Nexsolutions Inc. has implemented a comprehensive integrated system for Kato Models, renowned for their high-quality model trains. This initiative focuses on strengthening collaboration among Kato's production management system, their Product Lifecycle Management (PLM) system, and an internally developed performance tracking app. The goal is to support Kato Models' ambitious Factory Digital Transformation (DX) efforts.

A Step Towards Enhanced Management Practices

Kato Models, based in Shinjuku, Tokyo, has long been recognized for crafting stunningly intricate and high-performance model trains. The company leverages a management methodology known as “daily profit management,” which relies on sophisticated operational systems and IT infrastructure to visualize departmental profitability on a daily basis. This focus on accuracy and efficiency is vital for sustaining the brand's reputation in the competitive model train market.

Since 2012, NEC Nexsolutions and Kato Models have been collaborating to enhance both operational systems and IT infrastructure, with the overarching goal of realizing advanced Factory DX practices. As a result, employees can now better understand profit margins and focus on profitability, effectively fostering a culture of accountability and awareness across all levels.

(Above Image: The iconic HO D51 Standard Production model, a testament to Kato's commitment to quality.)

Achieving Operational Precision

The comprehensive implementation of the EXPLANNER/J production management system has enabled precise management of inter-departmental transactions. This system allows the processing of orders and purchases within the production operations, enhancing the capability for accurate profitability analysis across departments.

Kato Models has also integrated their PLM system, Obbligato, with the production management system and the performance tracking app. This synergy allows detailed management of the Bill of Materials (BOM) and Bill of Processes (BOP) data. By collecting actual work performance through a proprietary smartphone application, the data is seamlessly integrated into EXPLANNER/J, enabling visibility of costs per product and process.

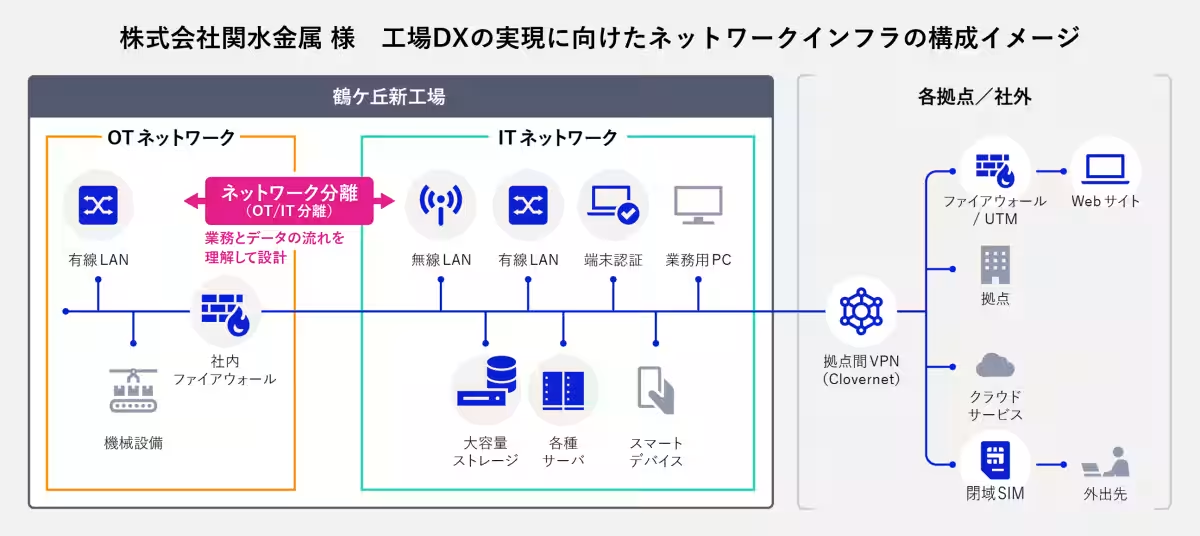

Connectivity and Security at Its Core

One of the standout features of this initiative is the adoption of a network architecture that distinctly separates Operational Technology (OT) from Information Technology (IT). This approach ensures both the safety and the usability of the activities carried out throughout the factory. A secure network infrastructure has been established, enabling real-time data aggregation from the factory floor, thus exemplifying a robust solution that meets contemporary security and functionality needs.

Representatives from NEC Nexsolutions will showcase the details of this transformative initiative at the Smart Factory Expo, taking place from September 17 to 19 at Makuhari Messe, Chiba.

A Commitment to Continuous Growth

NEC Nexsolutions is dedicated to supporting continual growth and competitive advantages in its clients' development and production processes. Through this strategic partnership, both companies are focused on not just accelerating Factory DX but also on delivering higher quality standards that resonate with customers worldwide.

In sharing these success stories and insights, the company hopes to inspire others in the manufacturing sector about the transformative power of digital technologies. The importance of a well-structured digital ecosystem in enhancing production capabilities cannot be overstated, especially for businesses like Kato Models, who continue to set the benchmark for quality in the model train industry.

- ---

For further details or inquiries regarding this initiative, please connect with NEC Nexsolutions’ Manufacturing and Equipment Solutions Group via email: [email protected].

Related Links

Conclusion

This collaborative endeavor is a prime example of how targeted digital transformations can greatly enhance the efficiency and output of manufacturing operations, paving the way for continuous improvement and long-term success.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.