Innovation in Cold Storage Sorting with GINFON's 3D Nexus Sorter

In an effort to improve efficiency in sorting frozen and refrigerated foods in cold environments, Nexa Ware, a joint venture between Tsubakimoto Chain Co. and KDDI Corporation, has conducted a trial implementation of the 3D Nexus Sorter. Developed and manufactured by GINFON, this cutting-edge three-dimensional cross-belt sorter aims to enhance operations at the Kitisai Logistics Center of Distribution Services, slated to begin operation on December 16, 2025.

The process of shipping frozen foods requires meticulous attention to various factors, including product size, shape, and shipping conditions, all of which need to be managed effectively in a cold storage environment. However, limitations in space and the lack of high-performance material handling equipment have significantly delayed the automation and efficiency enhancements required in this sector.

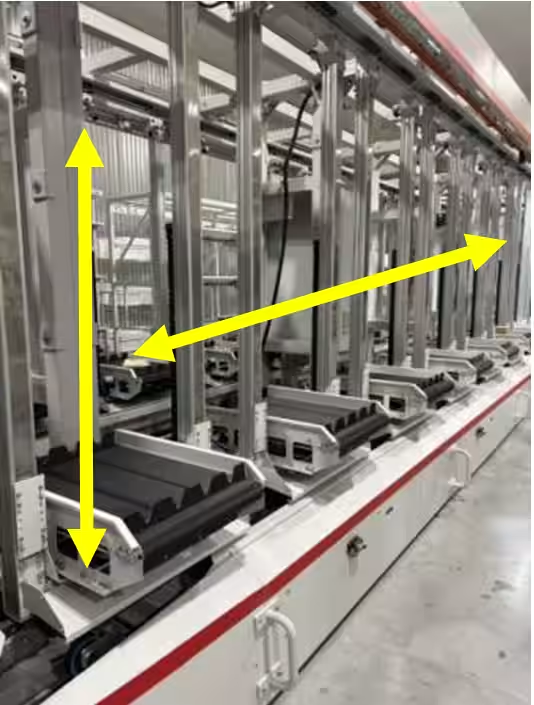

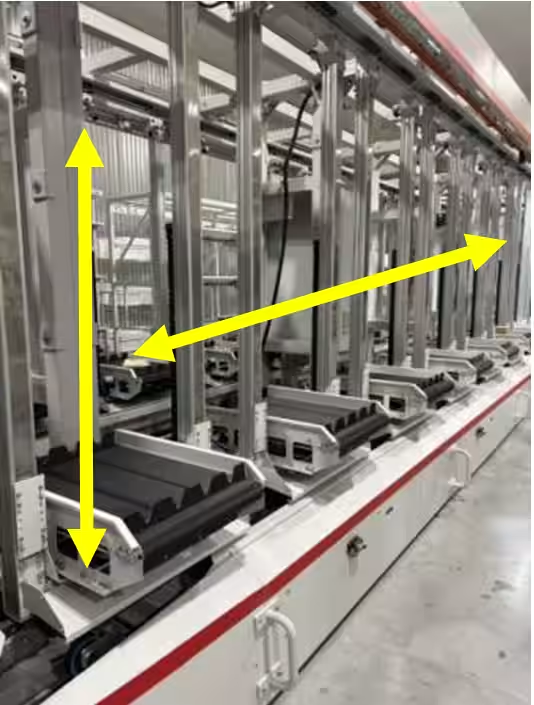

The 3D Nexus Sorter has been designed with these challenges in mind. It features an adjustable height cross-belt system that can rapidly sort items in a looped manner, achieving a maximum sorting capacity of up to 6,000 items per hour. This high efficiency minimizes the risk of shipping errors, ensuring high-quality and effective shipping operations, all while conserving precious space.

1. Space-saving Design: The unique cross-belt system operates within a compact framework while providing high-speed sorting capabilities. By elevating and lowering its cross-belt carriers, the sorter accurately handles a wide variety of products, which effectively reduces operational space requirements.

2. Flexible Multi-tier Chutes: With the ability to configure up to five tiers of chutes, the sorter can adapt based on daily shipping volume, the number of sorting destinations, and the nature of the items being sorted. This flexibility allows for simultaneous sorting for multiple clients or diverse product groups. Moreover, the process is made user-friendly since products can be added one by one through a single entry point, significantly reducing training time.

3. Adaptable Layouts: The 3D Nexus Sorter’s unit-based design enables easy adjustments to accommodate a variety of setup conditions. This feature not only supports flexible installation and extension but also caters to changes in handling volumes or product types efficiently. With a quick standard installation process that can be completed in under two weeks, it offers businesses the agility they need in dynamic markets.

4. Digital Transformation Through Data Utilization: The sorter incorporates real-time monitoring of operational data, allowing for remote services during breakdowns. This proactive approach provides alarms for potential failures and maintenance alerts, ensuring minimal downtime. By establishing data links between multiple facilities, it supports informed management decisions related to staff deployment, inventory, and sales planning.

The functionality of the 3D Nexus Sorter extends beyond cold storage operations. It is also capable of handling a vast range of products like apparel and room-temperature foods, contributing to the automation backbone needed for the future of logistics. By fostering a sustainable model for next-generation logistics through operational efficiency and stable performance, the 3D Nexus Sorter plays a pivotal role in the industry’s advancement towards improved automation.

Note:

1. Tsubakimoto Chain Co. is headquartered in Osaka and led by President Takashi Kimura. More at tsubakimoto.jp.

2. KDDI Corporation, based in Tokyo, is led by CEO Hiroji Matsuda. More at kddi.com.

3. Nexa Ware is headquartered in Chiyoda, Tokyo, with President Takashi Kitamura at the helm. More at nexaware.com.

4. GINFON, located in Minato, Tokyo, is chaired by CEO Xi Cai. More at ginfon.net.cn.

5. Distribution Services is based in Soka, Saitama, led by President Hideki Oba. More at ryutsu.co.jp.

The process of shipping frozen foods requires meticulous attention to various factors, including product size, shape, and shipping conditions, all of which need to be managed effectively in a cold storage environment. However, limitations in space and the lack of high-performance material handling equipment have significantly delayed the automation and efficiency enhancements required in this sector.

The 3D Nexus Sorter has been designed with these challenges in mind. It features an adjustable height cross-belt system that can rapidly sort items in a looped manner, achieving a maximum sorting capacity of up to 6,000 items per hour. This high efficiency minimizes the risk of shipping errors, ensuring high-quality and effective shipping operations, all while conserving precious space.

Key Features of the 3D Nexus Sorter

1. Space-saving Design: The unique cross-belt system operates within a compact framework while providing high-speed sorting capabilities. By elevating and lowering its cross-belt carriers, the sorter accurately handles a wide variety of products, which effectively reduces operational space requirements.

2. Flexible Multi-tier Chutes: With the ability to configure up to five tiers of chutes, the sorter can adapt based on daily shipping volume, the number of sorting destinations, and the nature of the items being sorted. This flexibility allows for simultaneous sorting for multiple clients or diverse product groups. Moreover, the process is made user-friendly since products can be added one by one through a single entry point, significantly reducing training time.

3. Adaptable Layouts: The 3D Nexus Sorter’s unit-based design enables easy adjustments to accommodate a variety of setup conditions. This feature not only supports flexible installation and extension but also caters to changes in handling volumes or product types efficiently. With a quick standard installation process that can be completed in under two weeks, it offers businesses the agility they need in dynamic markets.

4. Digital Transformation Through Data Utilization: The sorter incorporates real-time monitoring of operational data, allowing for remote services during breakdowns. This proactive approach provides alarms for potential failures and maintenance alerts, ensuring minimal downtime. By establishing data links between multiple facilities, it supports informed management decisions related to staff deployment, inventory, and sales planning.

The functionality of the 3D Nexus Sorter extends beyond cold storage operations. It is also capable of handling a vast range of products like apparel and room-temperature foods, contributing to the automation backbone needed for the future of logistics. By fostering a sustainable model for next-generation logistics through operational efficiency and stable performance, the 3D Nexus Sorter plays a pivotal role in the industry’s advancement towards improved automation.

Note:

1. Tsubakimoto Chain Co. is headquartered in Osaka and led by President Takashi Kimura. More at tsubakimoto.jp.

2. KDDI Corporation, based in Tokyo, is led by CEO Hiroji Matsuda. More at kddi.com.

3. Nexa Ware is headquartered in Chiyoda, Tokyo, with President Takashi Kitamura at the helm. More at nexaware.com.

4. GINFON, located in Minato, Tokyo, is chaired by CEO Xi Cai. More at ginfon.net.cn.

5. Distribution Services is based in Soka, Saitama, led by President Hideki Oba. More at ryutsu.co.jp.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.