Hexagon Celebrates 50 Years in Japan: Innovations for the Next Half-Century

Hexagon Celebrates 50 Years in the Japanese Market

2025 marks a monumental milestone for Hexagon Manufacturing Intelligence, headquartered in Chiyoda, Tokyo, as it celebrates 50 years of operations in Japan. Since its entry into the market in 1975, Hexagon has played a pivotal role in supporting innovation in manufacturing quality, facilitating businesses to enhance their operational efficiencies.

Japan’s manufacturing sector currently faces unprecedented challenges, including the “2025 cliff” related to digital transformation delays, sustainability requirements, and rising costs. On this significant anniversary, Hexagon aims to consolidate its expertise and advanced technologies to accelerate transformations within the industry, laying the groundwork for the future placing a strong emphasis on quality.

Highlights for 2025: Pursuing Quality to Enrich Lives

Through product development, Hexagon continues to seek enhancements in manufacturing quality while simultaneously enriching people's lives. The following initiatives highlight their commitment this year:

Strengthening Business Foundations for Accelerated Quality Innovations

To meet changing market demands and manufacturing quality requirements, Hexagon reinforced its foundations this milestone year. In July, the company streamlined operations by merging four subsidiaries focused on measurement technologies and CAD/CAM, launching Hexagon Manufacturing Intelligence. This integration reinforces its ability to support innovative technologies connecting design, production, and measurement, ultimately enhancing support quality.

Delivering New Value at Manufacturing Sites with Next-Gen Products

Hexagon has launched next-generation products and features aimed at improving operational efficiency and quality within manufacturing environments:

- - Next-Gen Laser Tracker for Aerospace and Energy Industries: The recently unveiled ATS800 laser tracker is designed to tackle inefficiencies in inspecting large structures in the aerospace and energy sectors. Its patented TruePoint technology enables high-precision scanning of up to 40 meters without the need for reflective targets. This innovation simplifies inspection processes, reducing inspection times from hours to mere minutes, thereby supporting modern production speeds and quality management automation.

- - Enhanced Reverse Engineering and Quality Assurance through Brand Integration: In April, Hexagon formalized the integration of the Geomagic brand, strengthening its portfolio in 3D measurement and reverse engineering. The tools developed by Geomagic enable manufacturers to redesign existing products, fostering the development of more sustainable products without compromising quality.

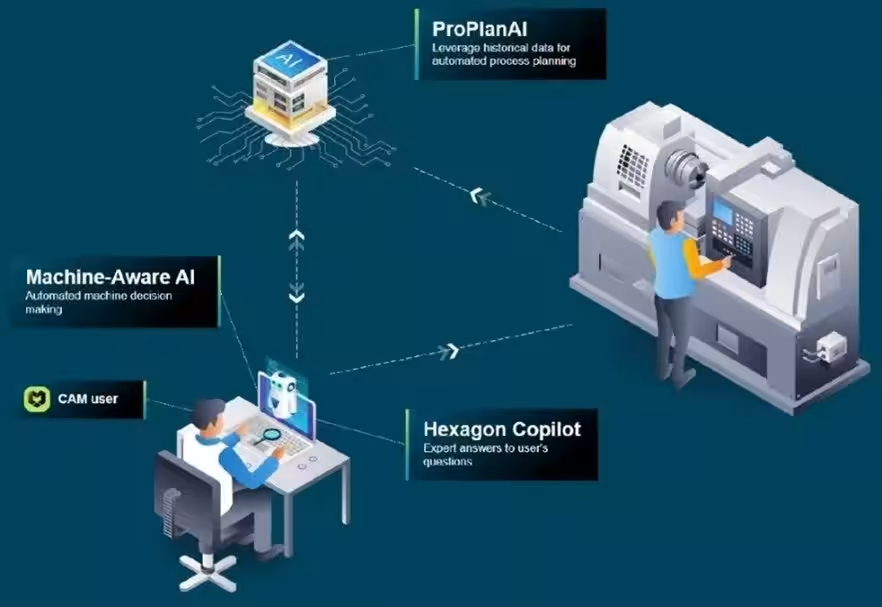

- - AI-Enhanced Digital Twin Compatible CAM System: Scheduled for unveiling at Japan's largest machining trade show, Mechatrotech Japan 2025, the next-gen CAM system ESPRIT EDGE features an AI component called ProPlanAI. This function automates the collection and analysis of past machining data from the cloud, aiding in both the passing on of technical knowledge and productivity increases.

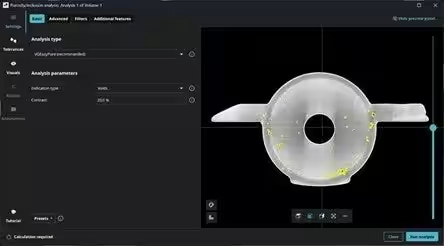

- - Industrial X-ray CT Analysis Software Update: The latest version of VGSTUDIO MAX, showcased at a user conference in November, integrates an award-winning defect detection tool. The upgraded AI delivers precise internal defect detection in metal and composite parts, significantly benefitting complete inspections.

Proven Technologies from F1 for Manufacturing Futures

In February, Hexagon renewed its long-standing innovation partnership with Oracle Red Bull Racing, reinforcing an 18-year relationship that showcases advanced measurement technologies under rigorous conditions. This collaboration promises to accelerate the development of intuitive and high-precision measurement solutions, benefitting Hexagon’s manufacturing product line. Proven F1 technologies that satisfy extreme quality and performance standards are now available to the global manufacturing industry.

Hexagon's CEO, Nozomu Ikeya, shared, "As we celebrate our 50th anniversary in Japan, we are dedicated to maintaining our push for innovation, contributing to the enhanced competitiveness of Japanese manufacturing. Our pride lies in our ability to solve challenges on the ground through our new products and solutions. For the next 10, 50 years, and beyond, Hexagon will continue to unify top-tier technology and expertise to enrich lives through quality."

Over the past 50 years, Hexagon has built a foundation of trust and technology, striving for quality that enhances lives. Through innovative solutions across various sectors, Hexagon is committed to creating a better future.

For the latest updates and articles on cutting-edge technologies, visit Hexagon’s advanced technology media, Hexagon Tech Bee.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.