JMAC Establishes MzX Research Group to Transform Japan's Manufacturing Industry

JMAC Establishes MzX Research Group

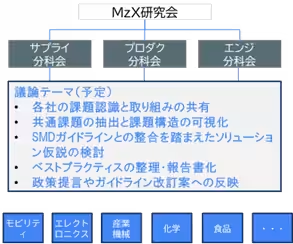

The Japan Management Association Consulting (JMAC), based in Minato, Tokyo, has launched the "Manufacturing Transformation (MzX) Research Group." This group serves as a platform for discussions aimed at expediting digital transformation (DX) in Japan's manufacturing sector. While terms like Industry 4.0 and DX have become more recognized, many companies still struggle with limited achievements and lack comprehensive strategies for implementation.

Purpose of the MzX Research Group

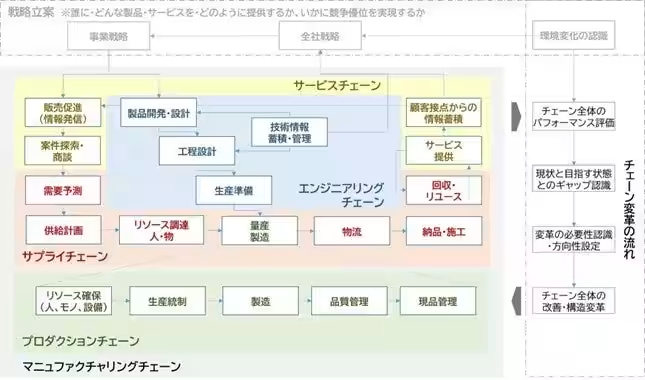

The MzX Research Group aims to tackle these challenges by leveraging the "Smart Manufacturing Development Guidelines (SMD Guidelines)," which will be officially released in 2024, with a revised edition planned for 2025. The guidelines, developed under the initiative of the Ministry of Economy, Trade, and Industry (METI) and NEDO, with JMAC responsible for writing, are designed to support DX activities among Japanese manufacturers. The key concept revolves around viewing internal initiatives not as isolated efforts but as interconnected value chains across various departments.

Together with participating companies, the group will focus on the four manufacturing chains proposed in the SMD Guidelines, facilitating discussions that drive innovations through the digitalization of information chains. As they cultivate insights that benefit the participating companies, the group also aims to provide new recommendations for the broader industry.

MzX Research Group Overview

Key Objectives

Based on the SMD Guidelines, the MzX Research Group will:

1. Support companies in their efforts towards manufacturing transformation.

2. Encourage participation in the MzX Award (MzX賞), established by the Japan Management Association (JMA), with applications starting in January 2026 and award announcements in February 2027.

3. Offer new recommendations to the industry.

4. Continuously evolve the SMD Guidelines themselves.

Initial Year Focus

In its first year, the discussions will mainly center around the food manufacturing industry, structured around three chains:

1. Engineering Chain

2. Production Chain

3. Supply Chain

Five to six companies will form three subcommittees to facilitate focused discussions on each chain. Here are a few research themes proposed for each subcommittee:

- - Engineering Chain: Discussing the ideal state and challenges from research and planning to mass production, particularly focusing on the engineering chain suitable for the food industry.

- - Production Chain: Develop common transformation scenarios and concrete solutions to promote the realization of smart factories.

- - Supply Chain: Organizing and reforming tasks necessary to build a smart supply chain in the food sector, addressing challenges intensified by anticipated demand decreases due to Japan's declining population.

Initial Year Schedule

- - Duration: January 2026 to November 2026

- - Format: Six bi-monthly meetings, with the final meeting featuring all three subcommittees together.

- - Venue: Japan Management Association Building or the Yaesu Satellite Office, Publica.

Detailed Agenda for Meetings

- - First Meeting (Jan 2026): Introduction

- - Second Meeting (Mar 2026): Setting Priority Issues

- - Third Meeting (May 2026): Digital Utilization in Transformation Challenges

- - Fourth Meeting (Jul 2026): Defining Industry Priority Challenges and Recommendations

- - Fifth Meeting (Sep 2026): Direction for Solving Priority Issues

- - Sixth Meeting (Nov 2026): Summary of Research Results

The SMD Guidelines: A Comprehensive Framework

The SMD Guidelines provide a robust foundation for the activities of the MzX Research Group. With a joint effort from METI and NEDO and guidance from JMAC's extensive experience in manufacturing reform, the guidelines will be published in June 2024 and updated in May 2025. They advocate for four core manufacturing chains:

- - Engineering Chain: Focusing on technology and information in product and process design.

- - Supply Chain: Managing the sequence of logistics from material procurement to product delivery.

- - Production Chain: Using internal manufacturing resources to process raw materials into finished products.

- - Service Chain: Enhancing service recognition and maintaining product value post-delivery.

As JMAC embarks on this exciting new venture, the MzX Research Group is poised to significantly influence the future landscape of Japan's manufacturing industry, driving progress towards a more digitally transformed and interconnected framework.

Topics Business Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.