Breakthrough Discovery of Universal Rules Governing Colloidal Aggregation for Advanced Material Design

Introduction

Recent research led by Yujiro Furuta and Rei Kurita at Tokyo Metropolitan University has uncovered a groundbreaking principle that dictates how colloidal particles aggregate during the curing process of functional materials. This finding holds potential implications for the design of adhesives, paints, and even advanced applications in nanotechnology and electronics.

Overview of the Research

High-performance materials, commonly utilized in adhesives and coatings, consist primarily of polymers and colloidal particles. When transitioning from a liquid state to a solid state through a process known as curing, the structure and arrangement of these colloidal particles significantly influence the material's properties. Historically, the understanding of how these particles organized during curing relied heavily on empirical methods, leaving a gap in predictive capabilities.

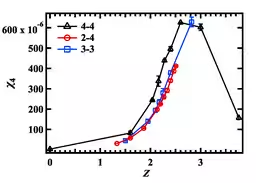

The research team employed numerical simulations to analyze the conditions under which colloids aggregate and the underlying mechanisms at play. A pivotal finding was that the colloidal behavior is governed by a universal rule: it is not the “degree of curing” but rather the “average number of bonds” (Z) between polymers that dictates the aggregation process. Notably, when Z exceeds 2.1, elasticity begins to develop within the material, leading to internal inhomogeneities that drive colloidal attraction, marking the onset of aggregation.

Key Findings

1. Unifying Framework: The team discovered that the aggregation of colloids can be uniformly explained through the average number of bonds (Z), rather than the curing rate (α).

2. Elasticity Emergence: Beyond a Z value of 2.1, materials begin to exhibit elasticity, leading to structural inhomogeneities.

3. Effective Attraction: The observed inhomogeneities generate effective attractions between colloidal particles, instigating their aggregation.

4. Competitive Dynamics: The ability of colloids to aggregate is influenced by the competition between the speed of curing and the mobility of the particles themselves.

5. Predictive Modeling: This newfound understanding allows for predictive modeling in the design of adhesives and functional coatings based on the parameter Z.

Background of the Study

Adhesives and paints are ubiquitous in our daily lives, serving not only fundamental functions like bonding and coloring but also providing essential properties such as durability, conductivity, rust resistance, and antiviral characteristics. In recent years, the shift towards curing reactions—rather than mere drying—to facilitate the transformation from liquid to solid states has prompted the need for a deeper understanding of colloidal behavior during this critical phase.

Despite its importance, the distribution of colloids during the curing process has traditionally been inadequately understood, hindering design capabilities. With the identification of a universal rule governing these processes, there is potential for more efficient and tailored material production.

Methodology

The research group conducted a systematic study utilizing various dispersions with differing functional groups on polymers to simulate the curing process of colloid-containing systems. They tracked the curing rates (α) and internal structural changes closely.

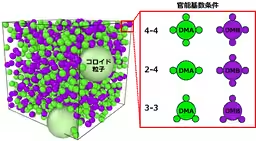

Two solvents, DMA and DMB, were selected, and the team employed a model that probabilistically bonded these molecules upon contact. By varying the number of functional groups to forms such as 4-4, 3-3, and 2-4, they investigated the curing dynamics and resulting colloidal structures over 100 simulation samples.

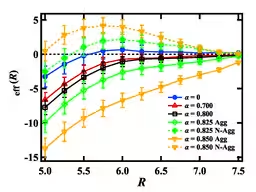

A significant observation was made when analyzing interaction dynamics at varying curing rates: above α = 0.825, marked differences in interaction patterns emerged, suggesting that long-range attractive forces began to play a role during aggregation—a pivotal moment that varied with different Z values.

Implications and Future Applications

This research profoundly enhances our understanding of colloidal systems, providing a clear parameter in the form of average bond number (Z) to design curing colloid dispersions systematically. This understanding could revolutionize the formulation of conductive films for electronic devices, robust adhesives, and environmentally sustainable coatings.

Moreover, the implications extend beyond traditional materials into realms like biocompatible materials, food engineering, and nanocomposite design. By establishing a simple yet universal parameter for elucidating colloidal behavior, this discovery could pave the way for innovations across various industries.

Conclusion

In summary, the findings of Furuta and Kurita's research signify a transformative leap in our understanding of colloidal aggregation. As we move forward, the ability to predict and design functional materials guided by the average number of bonds offers a new horizon for scientists and engineers alike, making significant strides toward sustainable and efficient material production for the future.

Reference

Furuta, Y., & Kurita, R. (2025). _Colloidal aggregation dynamics in curing systems unified by the number of cluster bonds_. Journal of Molecular Liquids. https://doi.org/10.1016/j.molliq.2025.128342

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.