Introducing OptFlow: Optimized Production Planning Solution for Factories

OptFlow: Revolutionizing Factory Planning Processes

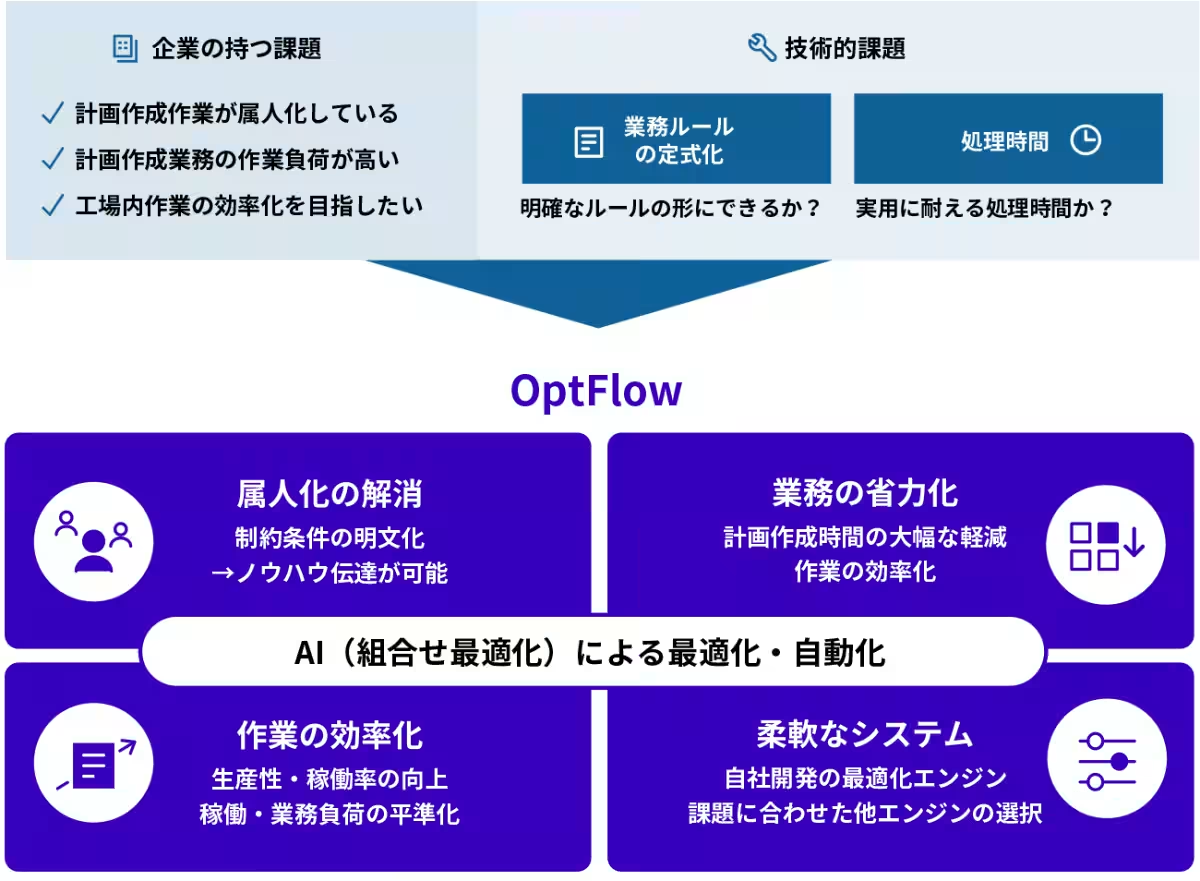

In an era where efficiency is crucial for maintaining competitive advantages, Motion Inc. is proud to announce the launch of its latest product, OptFlow. This state-of-the-art optimization solution assists factories in managing complex processes like inspection, production planning, maintenance scheduling, and workforce management. The aim is clear: to automate the planning process, ensuring approaches are not only optimal but also tailored to the specific challenges that businesses face.

What is OptFlow?

OptFlow is designed to transform the approach to planning in factories by utilizing a highly flexible engine developed by Motion Inc. The solution takes into account the vast array of factors that must be processed when creating effective operational plans. Using the company's expertise in combinatorial optimization, OptFlow can adapt to the specific requirements of each enterprise, enabling them to overcome technical challenges with ease.

Key Features of OptFlow

- - Data-Driven Automation: By capturing the invaluable experience and instincts of on-site workers, OptFlow converts this knowledge into a data-driven decision-making framework, allowing for high levels of automation in planning processes.

- - Speed and Efficiency: The core function of OptFlow is to accelerate the planning creation process while also enhancing its sophistication. This ensures that management decisions can be made swiftly and effectively.

- - Wide Range of Applications: OptFlow is not limited to one type of planning; it is adaptable across various scopes including production, inspection, maintenance, and employee scheduling, providing a comprehensive solution that meets diverse needs.

Background and Development

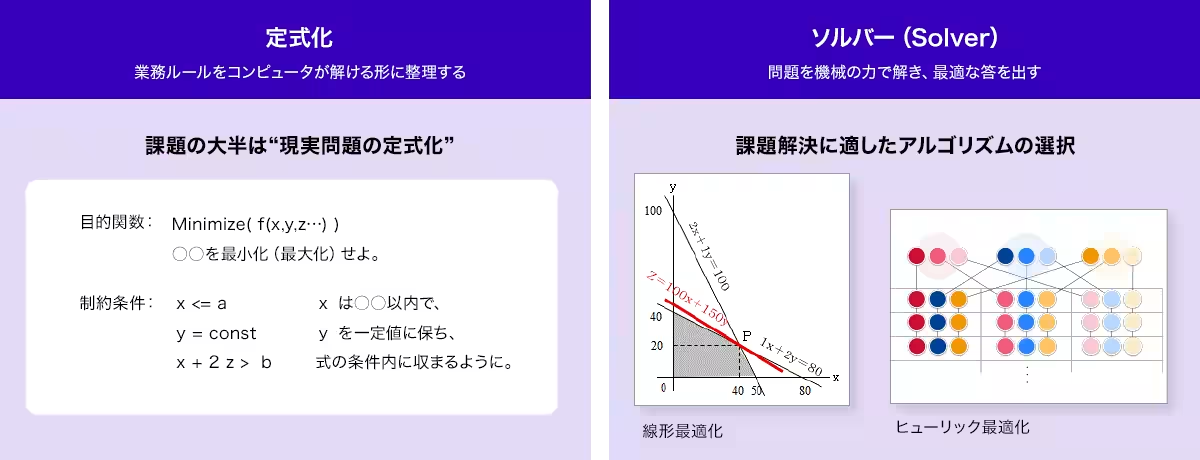

Numerous industries, particularly the food processing sector and chemical manufacturing, often require intricate planning due to multiple products and processes involved. These tasks usually demand not only an understanding of material quantities but also consideration of physical constraints, procedures, time constraints, employee skill levels, and other operational complexities. This leads to an exponential increase in potential combinations, creating a scenario that modern computing struggles to tackle without experiencing what is known as combinatorial explosion.

Moreover, the dependency on skilled individuals for critical decision-making can create a bottleneck when those employees leave or retire, leaving businesses at a disadvantage. OptFlow addresses these industry pain points by relying on Motion Inc.'s extensive statistical analysis experience to systematically formulate complex business rules. With the built-in optimization algorithms of the OptFlow engine, businesses can significantly reduce human labor, eliminate inefficiencies, and lessen over-reliance on specific personnel.

Automating Planning with OptFlow

The key to executing successful automation lies in accurately defining a company’s foundational business rules. OptFlow requires these rules to be clearly outlined, prioritized, and formatted in a way that is computationally digestible. Through this process, combined with selecting the appropriate optimization algorithm, the solution automates the planning tasks in a streamlined and effective manner. The OptFlow engine has proven its adaptability with successful applications in industries such as food processing and railway vehicle maintenance.

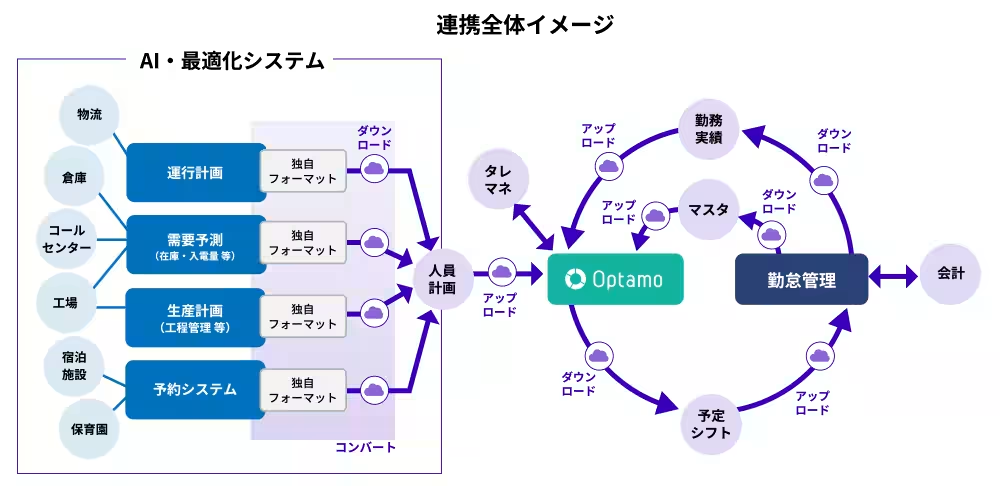

Collaboration with Optamo Series

OptFlow works in conjunction with the Optamo series, an existing service from Motion Inc. that optimizes work tasks and duty shifts using similar optimization technology. Since its inception in April 2018, Optamo has been integrated with over 17 attendance management systems in the country. This integration facilitates overall optimization by allowing OptFlow’s planned processes to inform Optamo's personnel requirements, bridging crucial external systems like attendance and accounting seamlessly.

Benefits of Using Optamo

Optamo enhances scheduling effectiveness by automatically creating fair and balanced shift and task schedules for staff. Utilizing statistical algorithms, Optamo considers staff capabilities when assigning roles, drastically reducing the planning workload. This leads to improved productivity and allows managers to focus on core responsibilities, thus enhancing overall operational efficiency.

Implementation Process

To integrate OptFlow into your organization, the following steps are followed:

1. Listening: Understanding your unique challenges.

2. Model Development: Creating a data-centric model.

3. Organizing Business Rules: Structuring and formalizing rules for clarity.

4. Prototype Development: Testing the optimization engine through proof of concept.

5. Deployment: Final implementation and fit-gap analysis.

Contact Information

For inquiries about OptFlow, please contact Motion Inc. Solution Sales Department via:

- - Email: [email protected]

- - Contacts: Sales Team - Orihara, Fujiwara

With its innovative features, OptFlow not only enhances operational efficiency but also prepares businesses for seamless future operations and growth. Join us in revolutionizing planning processes today!

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.