JAL Group Introduces Innovative Stretch Film Utilizing Biomass Materials

Introduction of Biomass Stretch Film by JAL Group

In a significant step towards sustainability, the JAL Group has announced the introduction of a biomass-based stretch film for cargo handling at domestic airports. This initiative marks the first time that a Japanese airline has adopted the mass balance approach for such materials. Scheduled for rollout after October 2025, this new handling material will be utilized for securing cargo during loading and storage, aiming to reduce CO₂ emissions by approximately 50 tons per year.

Understanding the Mass Balance Approach

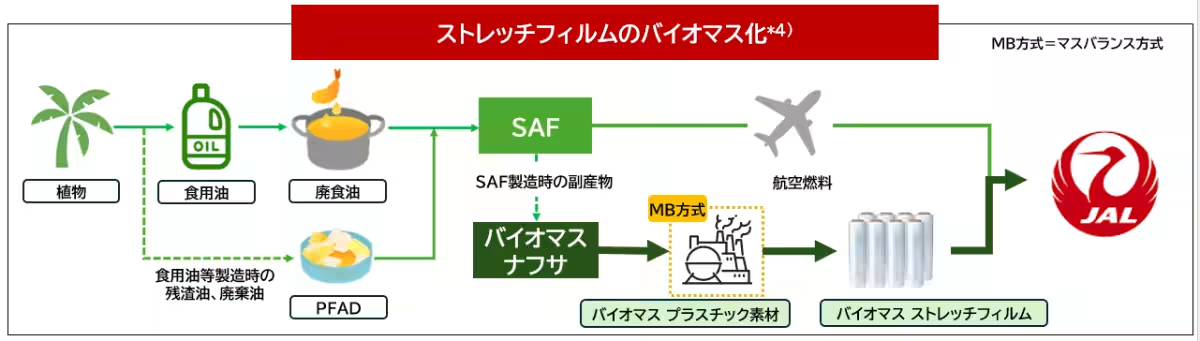

The mass balance method involves mixing multiple raw materials during the manufacturing process and properly assigning the characteristics of each raw material to the final product based on their proportions. This innovative approach allows for the production of stretch films with qualities equivalent to those made from 100% petroleum-derived raw materials while incorporating biomass components. Notably, the biomass materials used here are derived from bio-naphtha, a by-product of Sustainable Aviation Fuel (SAF) production, ensuring efficient resource utilization.

The new stretch film consists of around 25% biomass material, manufactured from polyethylene specifically allocated through the mass balance process. Ensuring that the handling quality remains equal to traditional films, JAL Group has verified this effectiveness through rigorous testing at Narita Airport’s cargo services.

Commitment to Sustainability

The JAL Group has set ambitious goals to reduce reliance on new petroleum-based plastics, consistently striving to incorporate environmentally considerate materials into its cargo business. By integrating this biomass stretch film into its operations, JAL will fully achieve the target of including 100% environmentally friendly materials in cargo supplies, as outlined in their mid-term management plan, Rolling Plan 2025. The group continues to search for ways to use limited resources effectively and lessen environmental burdens during their cargo operations.

The Manufacturing Partners

The production of this biomass stretch film has been made possible through collaborations with reputable companies such as Mitsui Chemicals, Prime Polymer, Tanix, and Tsuji Chemical Industry. These partnerships ensure high-quality manufacturing processes while upholding sustainability standards.

Conclusion

Through the introduction of this advanced stretch film, the JAL Group is not just responding to environmental challenges but is also setting a precedent within the industry. Their continued focus on sustainable cargo handling practices and dedication to reducing environmental impact highlights a promising future for eco-friendly initiatives within aviation and logistics.

As we look forward to witnessing the implementation of these innovations, it’s clear that sustainability does not mean compromising on quality or efficiency. JAL Group exemplifies how responsible practices can be harmoniously integrated into every aspect of business operations, paving the way for a greener aviation industry.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.