AI Utility Survey in Manufacturing: Challenges and Optimism Unveiled

AI Utility Survey in Manufacturing: Challenges and Optimism Unveiled

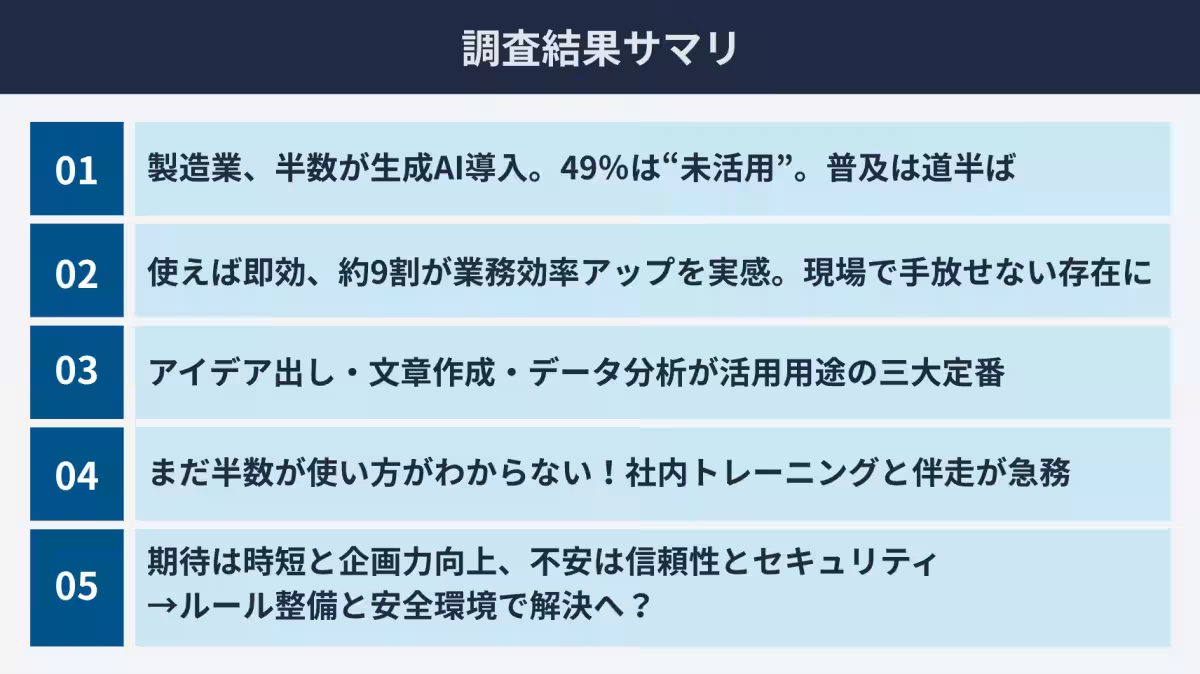

Arasaga Partners Corporation, headquartered in Shibuya, Tokyo, recently conducted a comprehensive survey exploring the utilization of generative AI among 331 professionals in Japan's manufacturing sector. The research highlights the current state of AI application in improving business operations, identifying both the benefits and existing hurdles.

Survey Overview

The survey, conducted as an internet-based questionnaire from July 22 to July 23, 2025, drew responses from 311 individuals engaged in various manufacturing roles across the nation. Although generative AI adoption has seen notable growth, nearly half of the respondents are still not utilizing it, revealing significant barriers in the industry.

Generative AI Adoption in Manufacturing

Approximately 51% of respondents reported some degree of generative AI utilization in their work processes. The breakdown is as follows:

- - Actively using: 16.3%

- - Partially using: 29.3%

- - Piloting: 5.4%

- - Interested but not using yet: 17.2%

- - Neither using nor interested: 31.7%

This distribution indicates a dual landscape: while half of the professionals have embraced AI, a substantial 49% remain hesitant or uninterested.

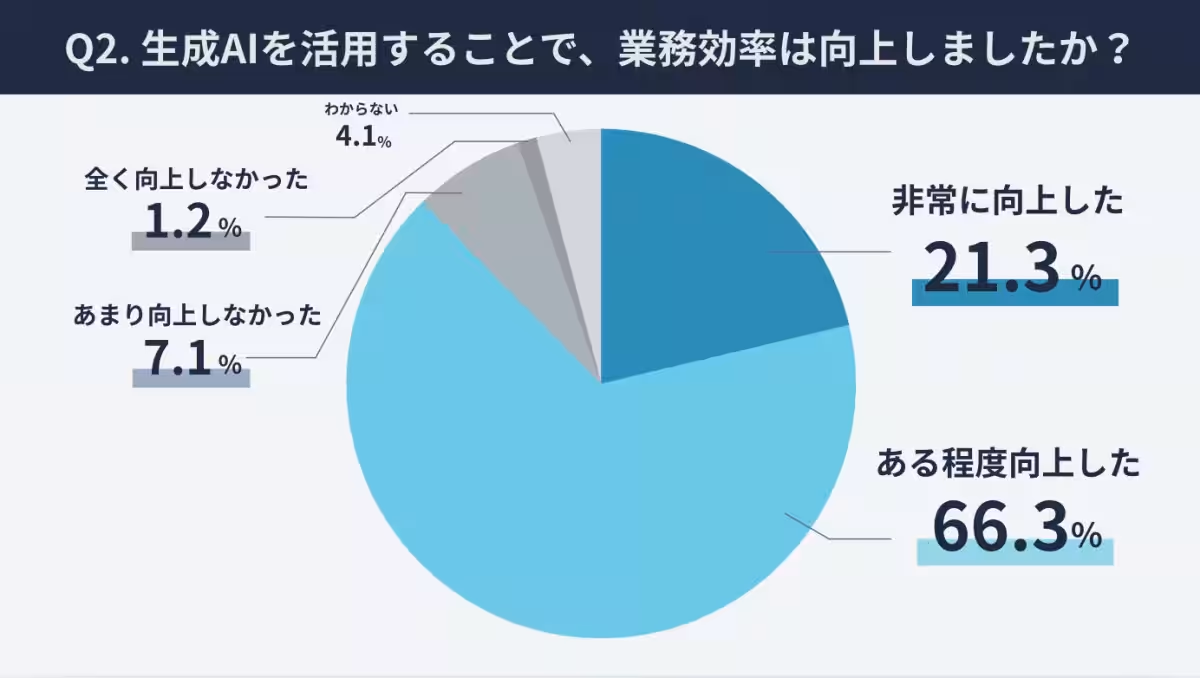

Impact on Operational Efficiency

The survey found a positive response regarding operational efficiency, with 87.6% of users signaling improvements:

- - Significantly improved: 21.3%

- - Moderately improved: 66.3%

- - Little improvement: 7.1%

- - No improvement: 1.2%

Nearly nine-out-of-ten users acknowledged enhancements in their workflows, particularly in terms of work speed and creativity.

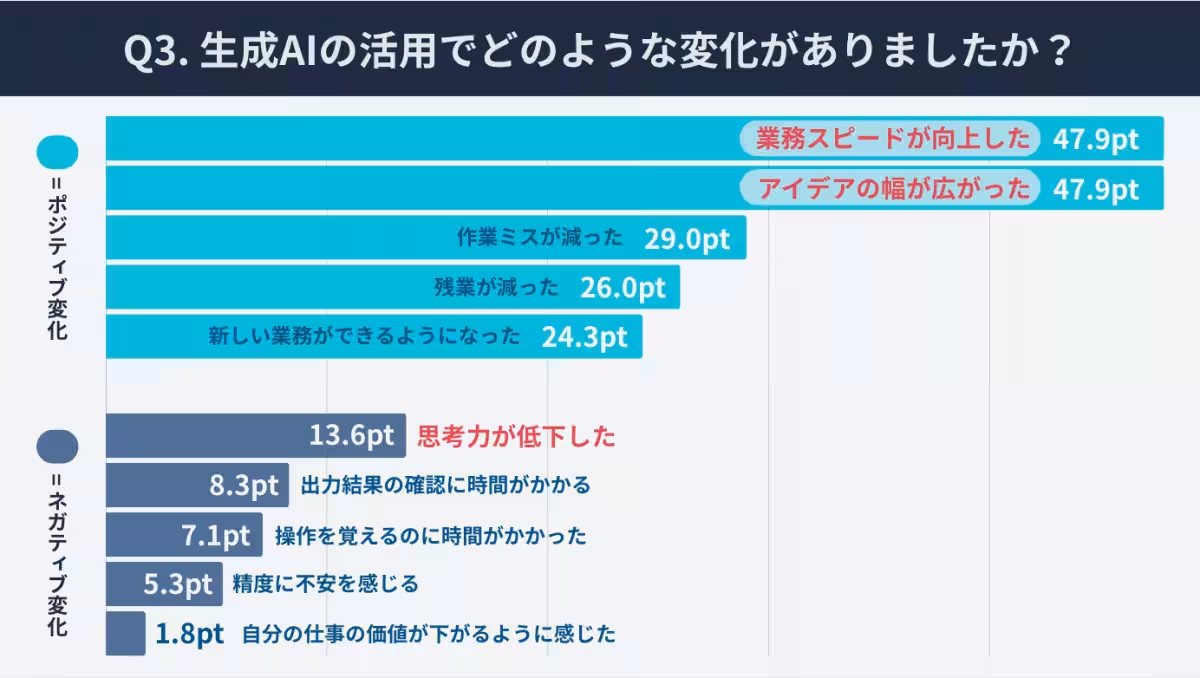

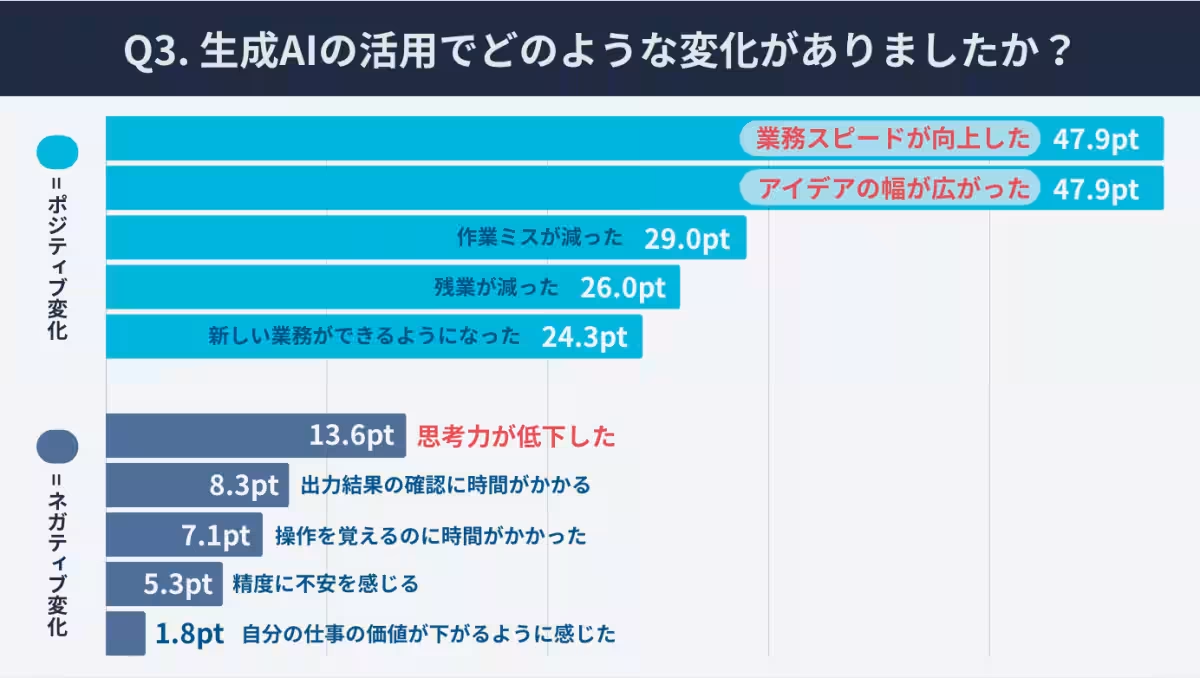

Positive Developments from AI Integration

The survey revealed several positive transformations attributed to generative AI:

- - Increased speed of operations: 47.9%

- - Expanded creative thinking: 47.9%

- - Reduced errors: 29.0%

- - Decreased overtime: 26.6%

- - Enabled new functions: 24.3%

Conversely, some respondents experienced setbacks related to reliance on AI, including:

- - Diminished critical thinking: 13.6%

- - Extended verification times: 8.3%

- - Challenges in adapting to new technology: 7.1%

These responses underscore the pressing need for organizations to reassess their processes and skills as they implement AI technologies.

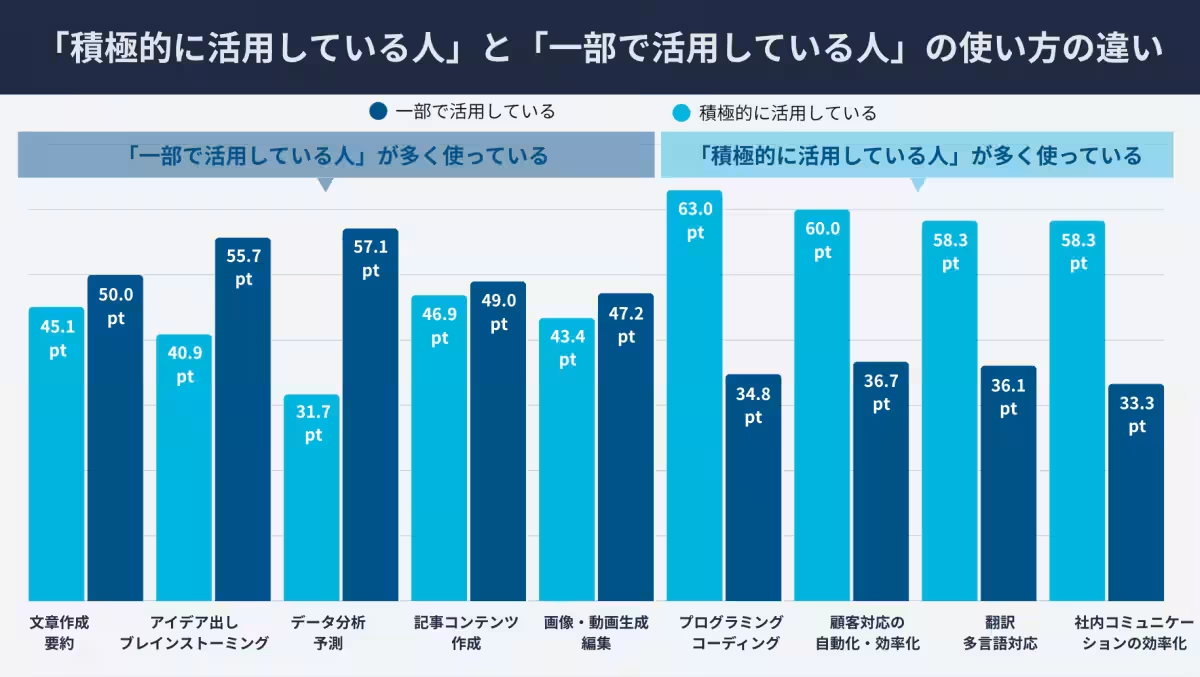

Areas of Application

Generative AI is being adopted in various capacities, with the following uses identified:

- - Idea generation and brainstorming support: 52.1%

- - Content creation and summarization: 48.5%

- - Data analysis and forecasting: 37.3%

- - Image and video generation/editing: 31.4%

Interestingly, the depth of adoption influences use cases. Regular users engage in more advanced operations, while less frequent users limit themselves to basic applications.

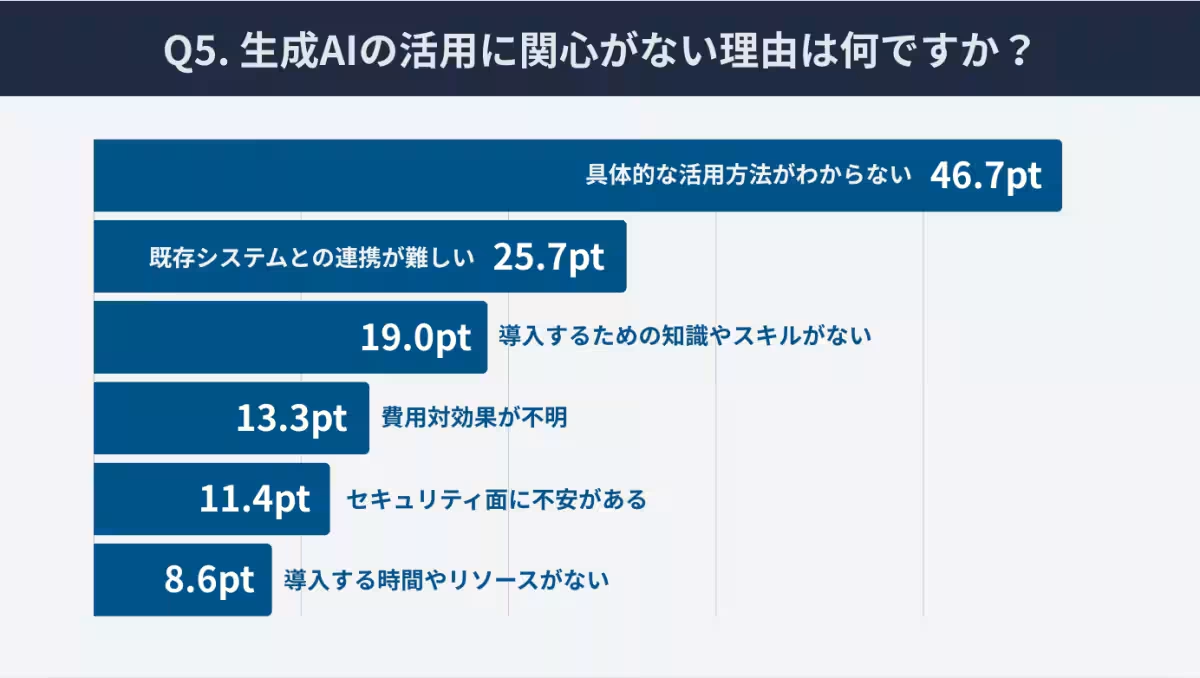

Barriers to AI Adoption

Despite advancements, many feel stymied, with 46.7% of non-users citing a lack of understanding of AI deployment methods. Other barriers include:

- - Integration with existing systems: 25.7%

- - Lack of necessary skills: 19.0%

- - Uncertainty around cost-effectiveness: 13.3%

Expectations and Concerns

Participants expressed optimism regarding generative AI's future in enhancing operational efficiency (38.1%) and the quality of ideas (33.5%). Conversely, concerns about accuracy (13.9%) and security risks (13.0%) were also noted. People are wary of the potential negative impact on employee capabilities and lack of structured internal guidelines—a critical concern for organizations aiming for seamless integration.

Conclusions

The survey underscores a critical juncture in the manufacturing industry's relationship with AI. With a significant percentage of the workforce recognizing the technology's potential but remaining on the sidelines, the sector stands at a pivotal moment. Arasaga Partners highlights the necessity for targeted education and concrete case studies to bridge the gap between awareness and application.

As the industry further navigates this transformative period, ongoing evaluation of impact, alongside enhancing training programs and addressing technical integration issues, will be vital to drive successful AI adoption across manufacturing landscapes.

Topics Business Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.