AI Platform Meviy to Launch Automated Quoting for Copper and Brass Parts

Introduction

On November 17, 2025, the AI-driven platform Meviy, developed by Misumi Group, will officially launch its automated quoting service for sheet metal parts made from copper and brass materials. This innovative service aims to significantly streamline the procurement process for these essential components used in various industrial applications.

About Meviy

Meviy is designed to simplify the procurement of mechanical parts by utilizing 3D data uploads for immediate AI-generated quotes. This platform has been recognized for cutting down the time typically required for part procurement by more than 90%, addressing inefficiencies in traditional processes. For the fourth consecutive year, Meviy has achieved No. 1 market share in Japan’s online mechanical parts procurement sector and won the Prime Minister’s Award at the 9th Monozukuri Japan Awards.

Copper and Brass Materials

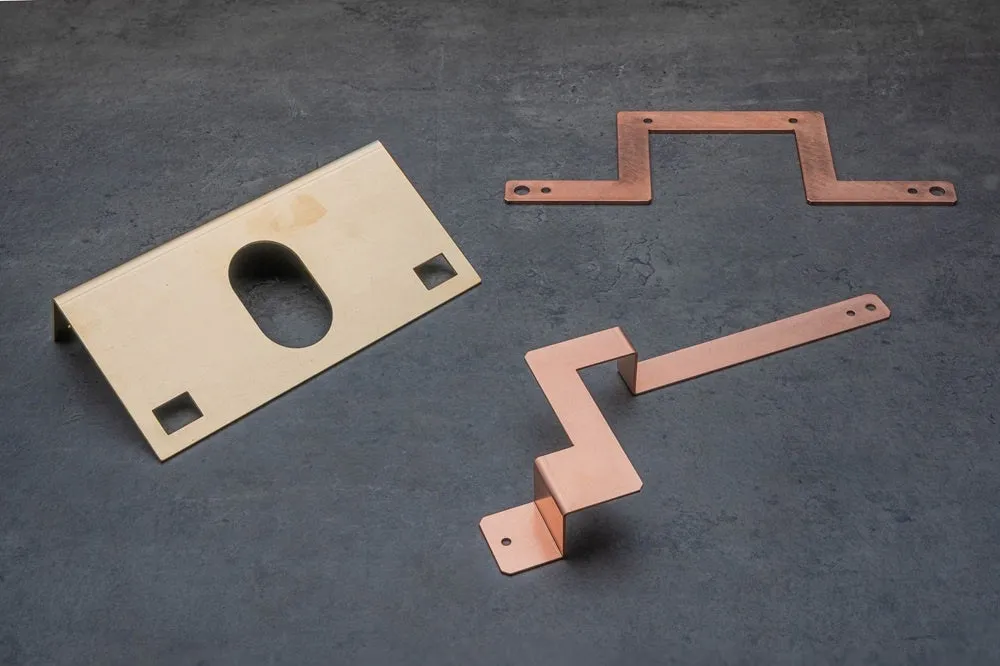

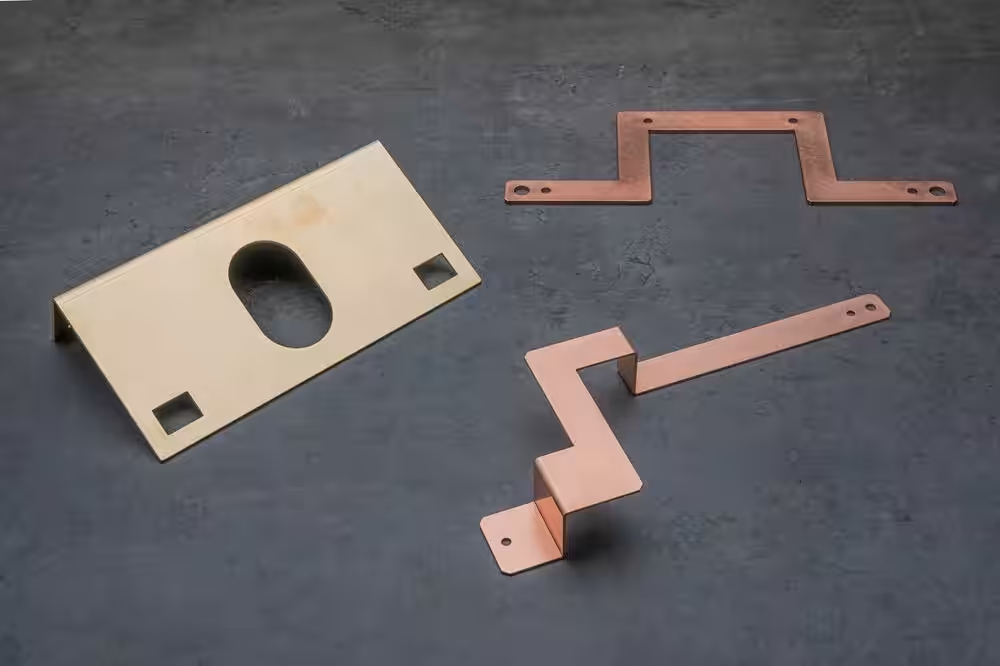

Copper, known for its excellent thermal and electrical conductivity, is a critical material in the production of parts such as busbars used in electrical and electronic devices. Pure copper variants, including C1020 oxygen-free copper and C1100 tough pitch copper, are particularly valued for their efficiency in transmitting electrical currents. Brass, particularly the C2801P variant, is an alloy of copper and zinc that offers superior durability and corrosion resistance, making it ideal for various mechanical components, including covers that prevent spatter during welding processes.

Despite their advantages, both copper and brass parts come with challenges in terms of processing. Copper, for example, reflects light excessively during laser processing, leading to a higher risk of discoloration and deformation. Additionally, the complexity of working with these materials has limited the number of capable manufacturers, often resulting in extended lead times and delivery uncertainties.

Addressing Customer Demands

In response to customer feedback, including requests for the capability to handle copper and brass materials, Meviy has decided to extend its services. Not only will automated quoting for these materials be introduced, but the production system will be enhanced and processing specifications standardized to ensure consistent quality. This enhancement allows for parts to be shipped as soon as two days after the order is placed, reducing the lengthy procurement times traditionally associated with copper material parts. With this new offering, even urgent design changes can be addressed swiftly, leveraging only 3D data for expedited orders.

Service Overview

- - Launch Date: November 17, 2025

- - Target Service: Sheet metal machining

- - New Materials Offered:

- Brass: C2801P

- - Thickness Range: 1.0mm – 3.0mm

- - Lead Time: Parts can be shipped as soon as two days

For detailed service information, visit the Meviy service site.

The Future of Manufacturing with Digital Model Shift

Misumi Group continues to innovate and transform the manufacturing process using digital technologies. In 2000, they pioneered internet ordering services in the industry, allowing clients to complete part selections and orders online seamlessly. The introduction of Meviy has marked a significant milestone in the drive for improved productivity in the industrial sector.

As Misumi positions the "Digital Model Shift" at the core of their growth strategy, they aim to offer enhanced value to clients through transformative digital changes. The objective is to dramatically enhance productivity in design and production environments while simultaneously achieving cost savings through optimized procurement services.

Conclusion

In summary, with the introduction of automated quoting for copper and brass parts, Meviy not only advances the efficiency of the procurement process but also strengthens its commitment to meeting customer needs in a rapidly evolving manufacturing landscape. Misumi Group is dedicated to continuing this journey, ensuring that every customer's time is transformed into valuable outcomes, fostering joint sustainable growth in the industry.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.