Bingo Tsukemono Implements i-Reporter to Achieve Full Digital Transformation in Just One Year

Enhancing Efficiency: How Bingo Tsukemono Transformed Operations with i-Reporter

Bingo Tsukemono Co., Ltd., a prominent player in the pickled food industry, successfully utilized the i-Reporter system, delivering a substantial digital transformation across four departments in just one year. This remarkable achievement not only saved 182 hours of manpower annually but also eliminated the risk of losing important paper documents, enhancing operational accuracy significantly.

Background and Challenges

Founded in 1946, Bingo Tsukemono, based in Fukuyama City, Hiroshima Prefecture, has established itself as one of the leading companies in the pickled food sector. With a commitment to quality, they successfully obtained the FSSC 22000 certification for their production facilities. However, as they employ a diverse workforce that includes many foreign staff, Bingo Tsukemono faced significant challenges regarding record-keeping using paper documentation. The issues highlighted included:

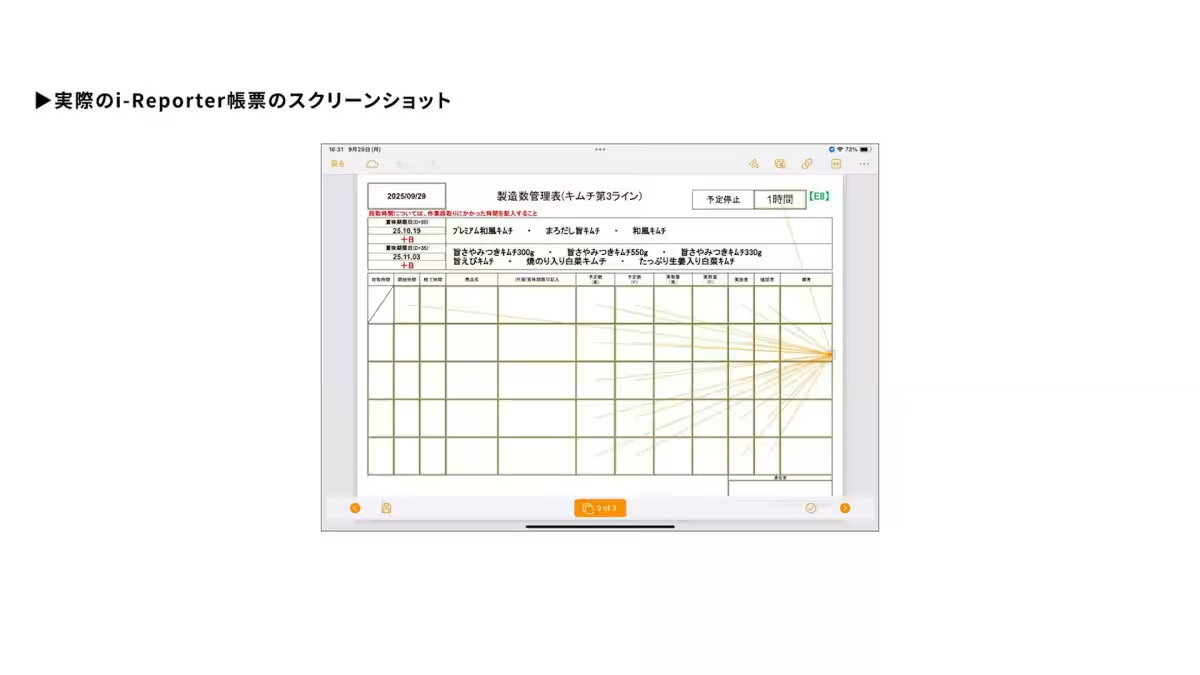

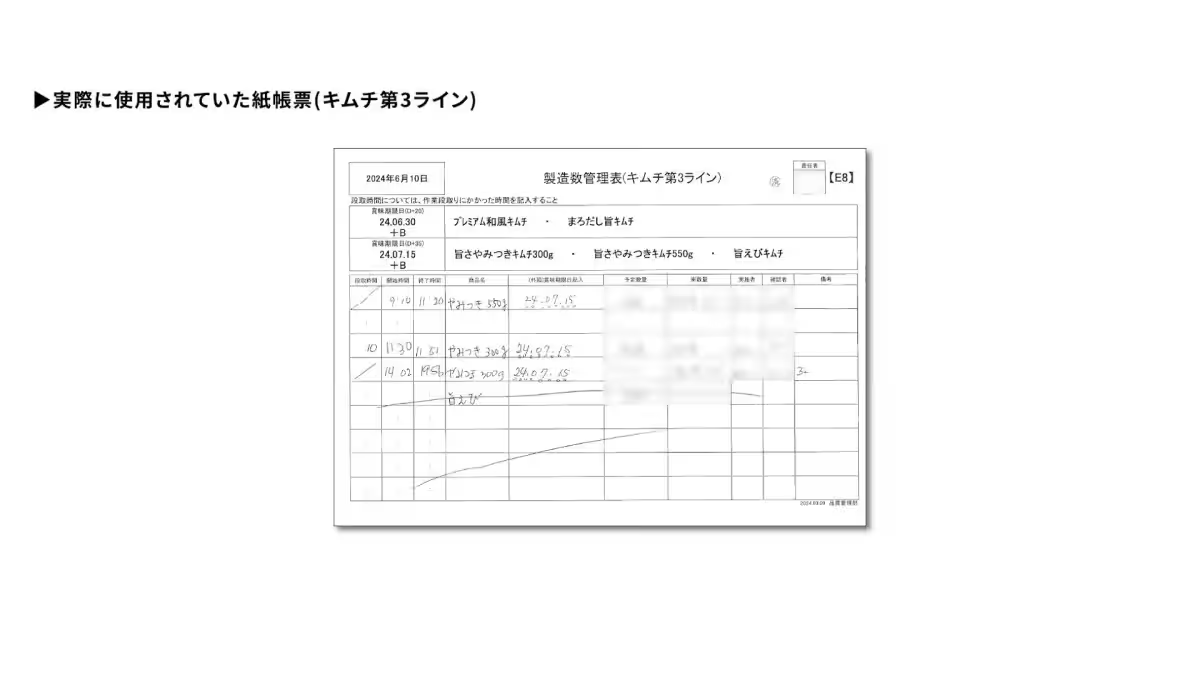

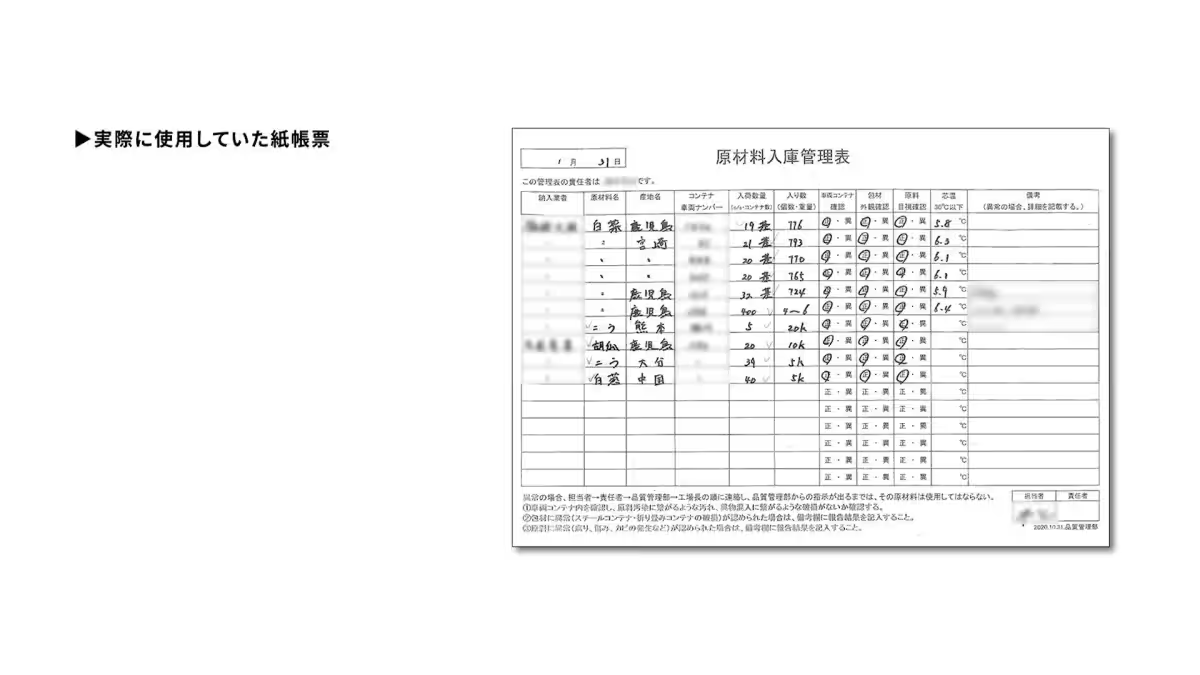

- - Manufacturing Record Management: Classifying and sorting daily production records took up to 30 minutes, resulting in a steep annual cost of 182 hours.

- - Handling Paper in Moist Environments: Their operation employed laminated papers that would often lead to smudging and poor readability due to ink bleeding.

- - Handwriting Challenges: Foreign staff faced difficulties in handwriting records, leading to potential inaccuracies—examples include confusing the numeral “1” with “7”.

- - Risk of Document Loss: The inadvertent failure to make photocopies could result in the loss of critical records.

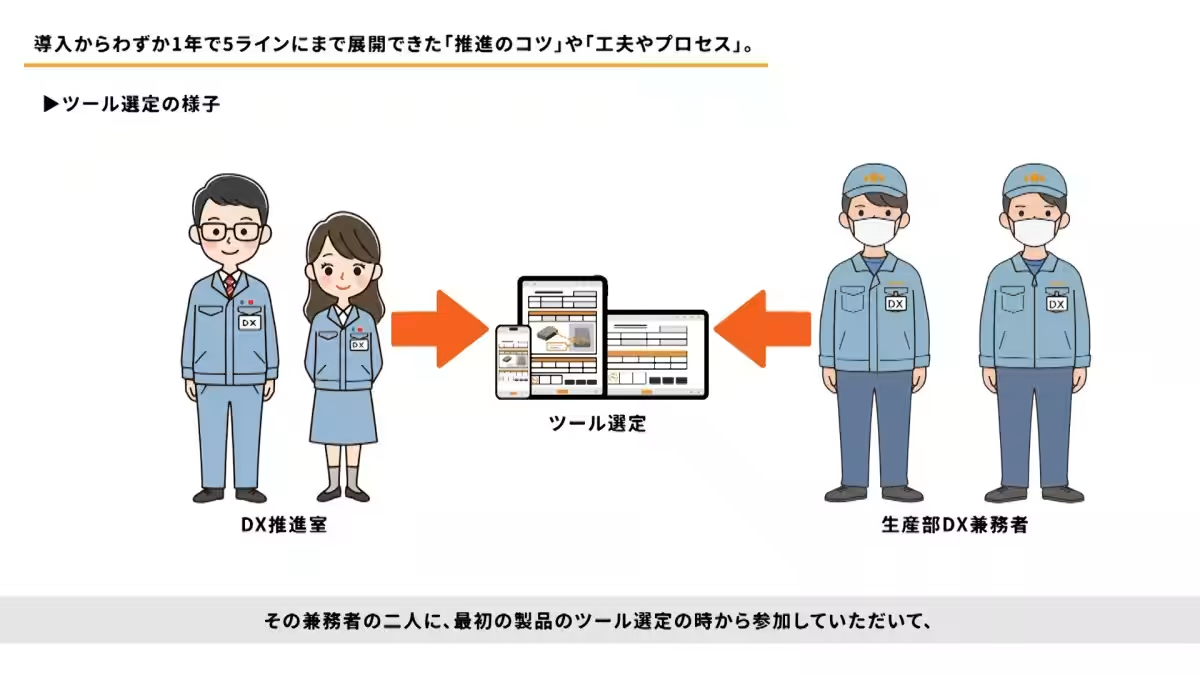

In response to these challenges, Bingo Tsukemono decided to implement the i-Reporter system in 2024, establishing a collaborative environment involving the DX Promotion Office and personnel from various departments to promote a field-driven approach to digital transformation.

Key Points of Implementation

The decision to adopt i-Reporter was strategic for several reasons:

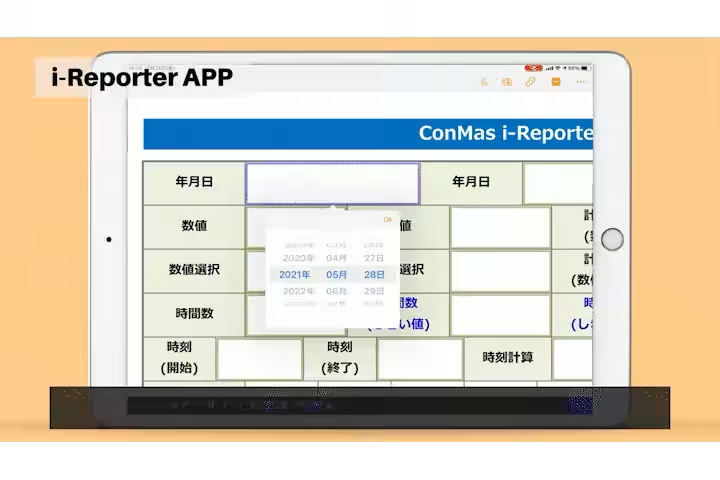

1. Easy Transition: The system maintains existing paper layouts, facilitating a seamless transition to digital that minimizes training costs.

2. Field-Driven Approach: By fostering cooperation between DX promoters and department staff, they were able to tackle challenges from a ground-level perspective.

3. Gradual Rollout: The implementation began with a single production line, gradually expanding based on feedback from the field.

Significant Impacts and Benefits

1. Improvements in Production Record and Quality Management

Before: 30 minutes were required daily just for the classification of production records, consuming valuable staff time.

After: The transition to i-Reporter eliminated this task entirely. Instead of managing paper records, data could now be submitted digitally, effectively reducing the risk of document loss. The system ensures essential fields are filled, minimizing the chances of record omissions and allowing same-day reviews and corrections.

- - Result: An annual reduction of 182 hours, improved record accuracy, and lower costs on copy paper, alongside streamlined audit processes.

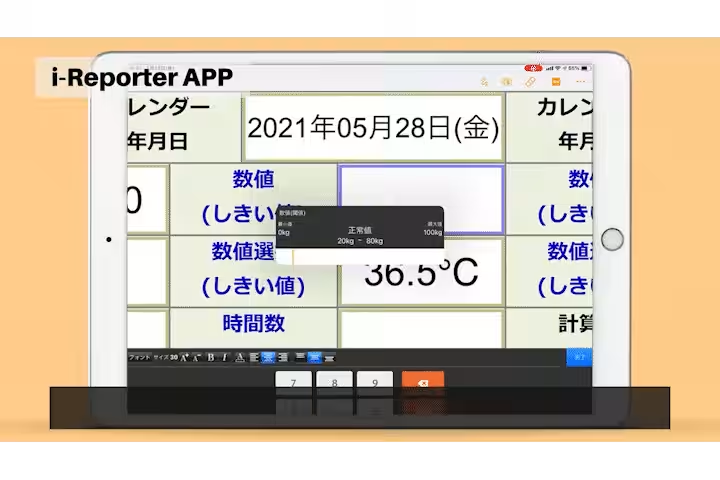

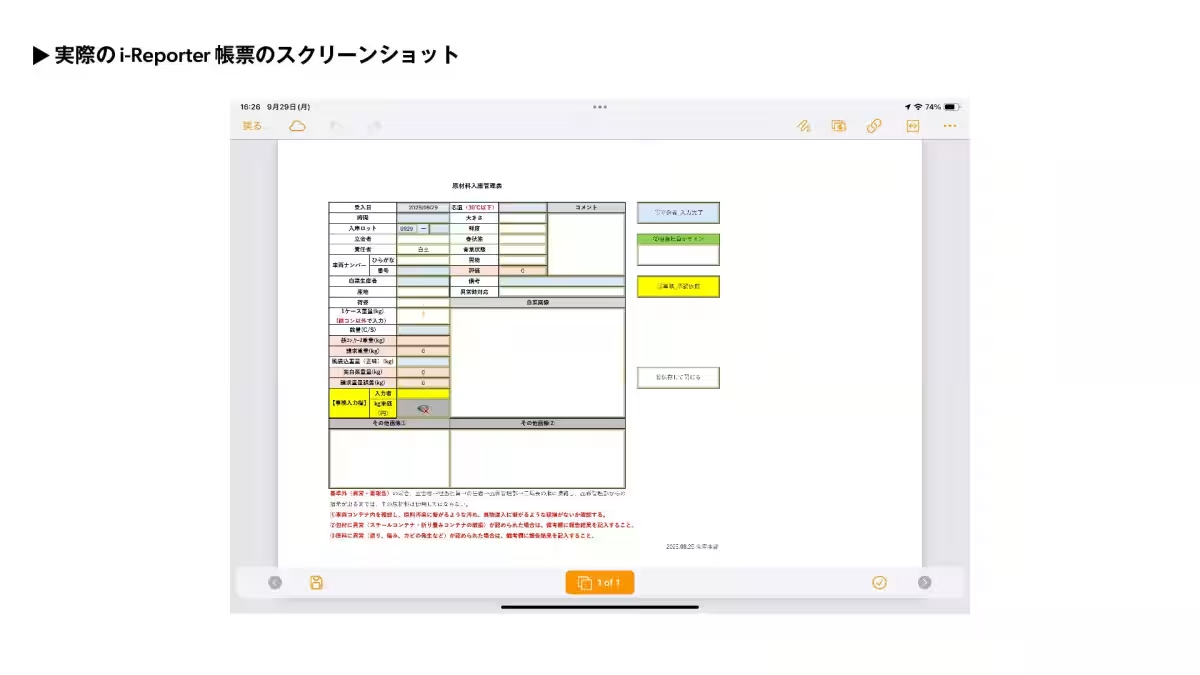

2. Enhancements in Quality Assessment for Cabbage Reception

Before: Quality assessments during the reception of cabbage were subjective and prone to inconsistencies.

After: An automated system captures images and records evaluation scores. Data points such as core temperature and leaf condition are selected via dropdown menus, allowing for standardized calculation of quality ratings, which can be communicated back to farmers to improve raw material quality.

- - Benefit: This objective assessment has received positive feedback from farmers, creating a continuous improvement cycle for supplier quality.

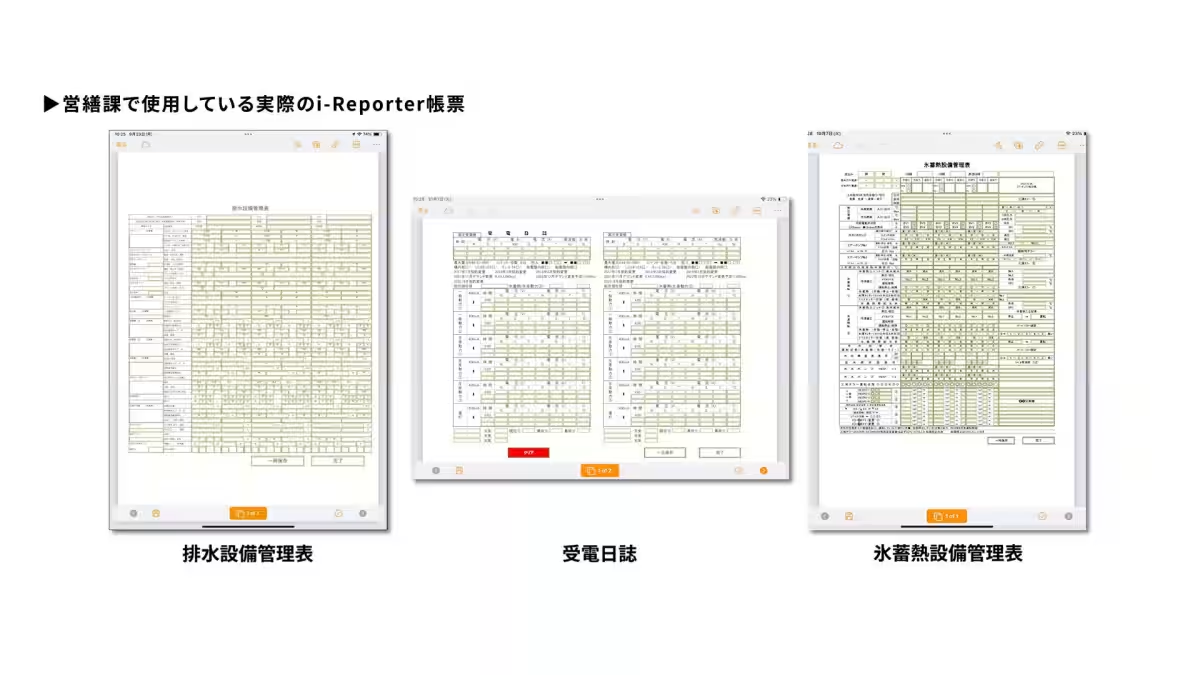

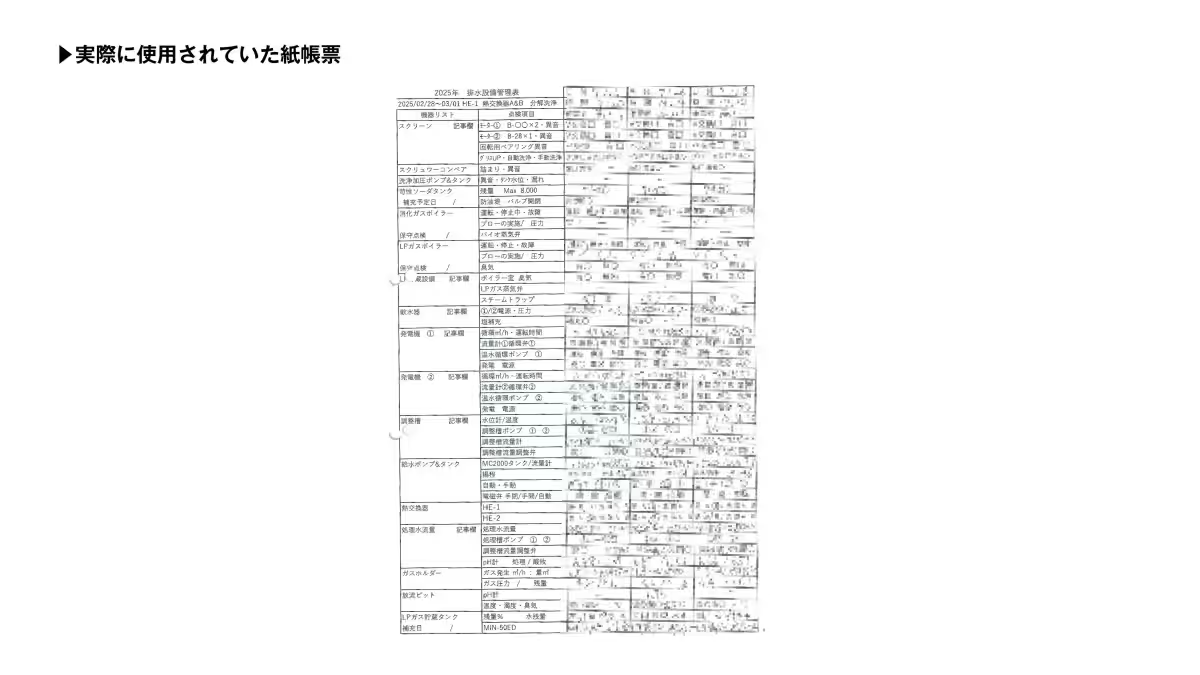

3. Streamlined Equipment Inspection for the Maintenance Department

Before: Equipment inspections faced challenges in adverse weather, often damaging paper forms.

After: By digitizing inspection forms for facilities like wastewater treatment, staff can now utilize iPads that withstand outdoor conditions, reducing the need for tedious manual data entry.

- - Outcome: Significant efficiency gains in data aggregation processes and faster anomaly detection through visual graphing.

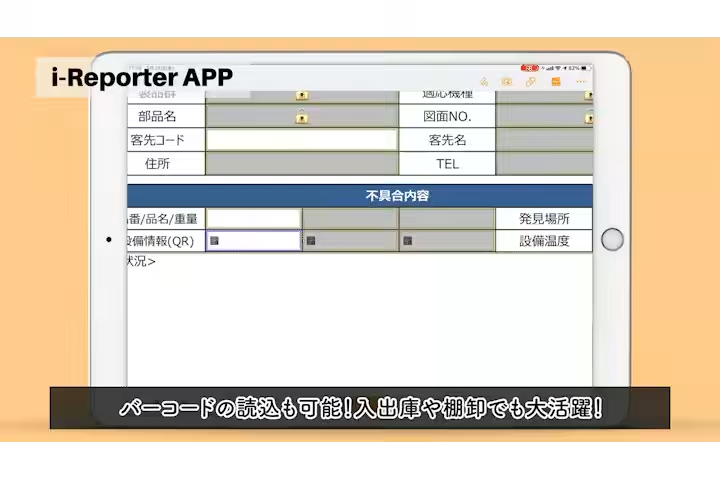

4. Accurate Record Keeping for Diverse Staff

To accommodate many foreign workers, transitioning from handwritten records to dropdown selections allowed accurate documentation without handwriting issues.

- - Impact: This inclusive digital recording system improved traceability, an essential factor in the food manufacturing industry.

Future Outlook

Bingo Tsukemono is committed to advancing their DX initiatives centered around the i-Reporter system for enhanced operational efficiency and accuracy. Future plans involve utilizing the accumulated data to support production planning and operational analysis while considering implementing Business Intelligence tools for data visualization. By pinpointing reasons for downtime, they hope to expedite the improvement cycle, ultimately increasing productivity further.

For more details on Bingo Tsukemono’s i-Reporter success story, visit: Bingo Tsukemono i-Reporter Case Study

Company Overview

Bingo Tsukemono Co., Ltd.

- - Founded: 1946

- - Head Office: 1613-47 Hoonseiji, Ekimae-cho, Fukuyama, Hiroshima Prefecture 720-2413

- - Business: Manufacturing and sales of pickled foods and kimchi

- - Production Facilities: Main plant (Hiroshima Prefecture), Kanto plant

- - Quality Certification: FSSC 22000 for both main and Kanto plants

- - Official Website: Bingo Tsukemono

Introducing i-Reporter - A market leader in field reporting solutions, utilized by over 4,500 companies. Offering a no-code solution, it simplifies digitalizing familiar paper forms, making the transition smooth for users without programming knowledge.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.