Introducing the Cutting-Edge FUNMAT PRO 310 APOLLO 3D Printer at TCT Japan 2026

Sunstella Unveils the Innovative FUNMAT PRO 310 APOLLO

Sunstella Co., Ltd., based in Tokyo, is set to introduce the latest high-end 3D printer model, the FUNMAT PRO 310 APOLLO, from the global industrial 3D printer manufacturer INTAMSYS. This exciting reveal will take place at TCT Japan 2026, which will be held from January 28 to January 30, 2026, at Tokyo Big Sight, South Hall 3. This will be one of the largest 3D printing exhibitions in Japan.

The FUNMAT PRO 310 APOLLO is designed for the continuous production of advanced engineering plastics, including PEEK, PAEK, and PEKK, utilizing a new generation of FFF (Fused Filament Fabrication) technology.

Key Features

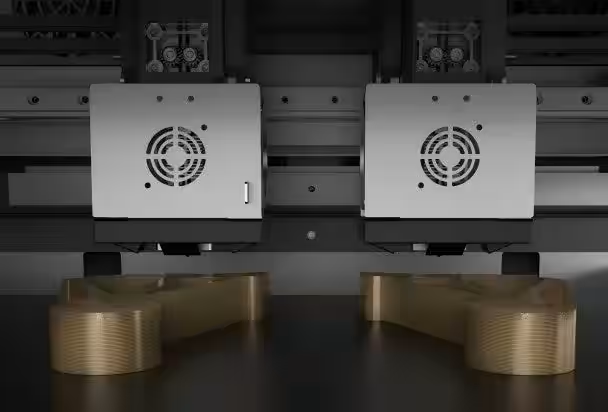

- - High-Speed Printing with PEEK and PEKK: This 3D printer supports high-speed printing of up to approximately 200 mm/s. The unique dual nozzle system optimized for PEEK and PAEK materials enables a fourfold increase in speed compared to traditional PEEK-compatible printers, making it ideal for applications in aerospace, automotive, and medical fields.

- - Designed for Continuous Production: A notable feature includes the dual 3kg active drying box, which minimizes material change interruptions and allows for stable continuous operation, enhancing productivity. Its real-time material recognition and print history logging are integral components of the INTAMQuality™ system, ensuring quality control and traceability.

- - Superior Thermal Management: Capable of reaching a chamber temperature of 100℃ and a build plate temperature of 160℃, this printer effectively minimizes thermal shrinkage, thus allowing for high precision and stable dimensional accuracy. It can also manage materials that are challenging for most 3D printers, such as PC-ABS and PPS, while reducing odors produced during high-temp engineering plastic printing.

Product Specifications

- - Printing Method: Fused Filament Fabrication (FFF)

- - Build Volume: Single nozzle: 305 × 260 × 260 mm, Dual nozzle: 260 × 260 × 260 mm

- - Layer Thickness: 0.1 - 0.3 mm

- - Number of Nozzles: 2 (IDEX system)

- - Nozzle Maximum Temperature: 450 ℃

- - Maximum Printing Speed: Up to 500 mm/s (200 mm/s with PEEK materials)

- - Maximum Acceleration: Up to 8,000 mm/s²

- - Additional Functions: Includes alarms for nozzle clogging, build plate overheating, filament break detection, power recovery printing, remote monitoring, and software/hardware OTA updates.

Exhibition Information

Exhibition Overview

Event Name: TCT Japan 2026

Date: January 28 - January 30, 2026

Venue: Tokyo Big Sight, South Hall 3

Sunstella Booth: 3S-H03

Admission: Free (e-invitation available at registration link).

Future Sales and Consultation

After the exhibition, domestic sales will commence progressively once product validation is complete. Sunstella also offers corporate support, maintenance, and material optimization consultancy.

About Sunstella Co., Ltd.

Established in March 2007 and headquartered in Toshima, Tokyo, Sunstella specializes in 3D printing equipment and materials, having achieved annual sales of over 3,500 units. With a customer-centric approach, Sunstella emphasizes reliability with support services, assured pricing, and a comprehensive shopping experience, consistently enhancing its reasons for customer choice.

Company Information

Headquarters: 〒170-0013 Tokyo, Toshima, Higashi-Ikebukuro 5-7-3, 6F Higashi-Ikebukuro Building

CEO: Yusuke Wada

Capital: 10 million JPY

Website: sunstella.co.jp

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.