Japan Launches PrintHub: A Decentralized 3D Printing Farm for Local Manufacturing

Japan's Revolutionary 3D Printing Initiative: PrintHub

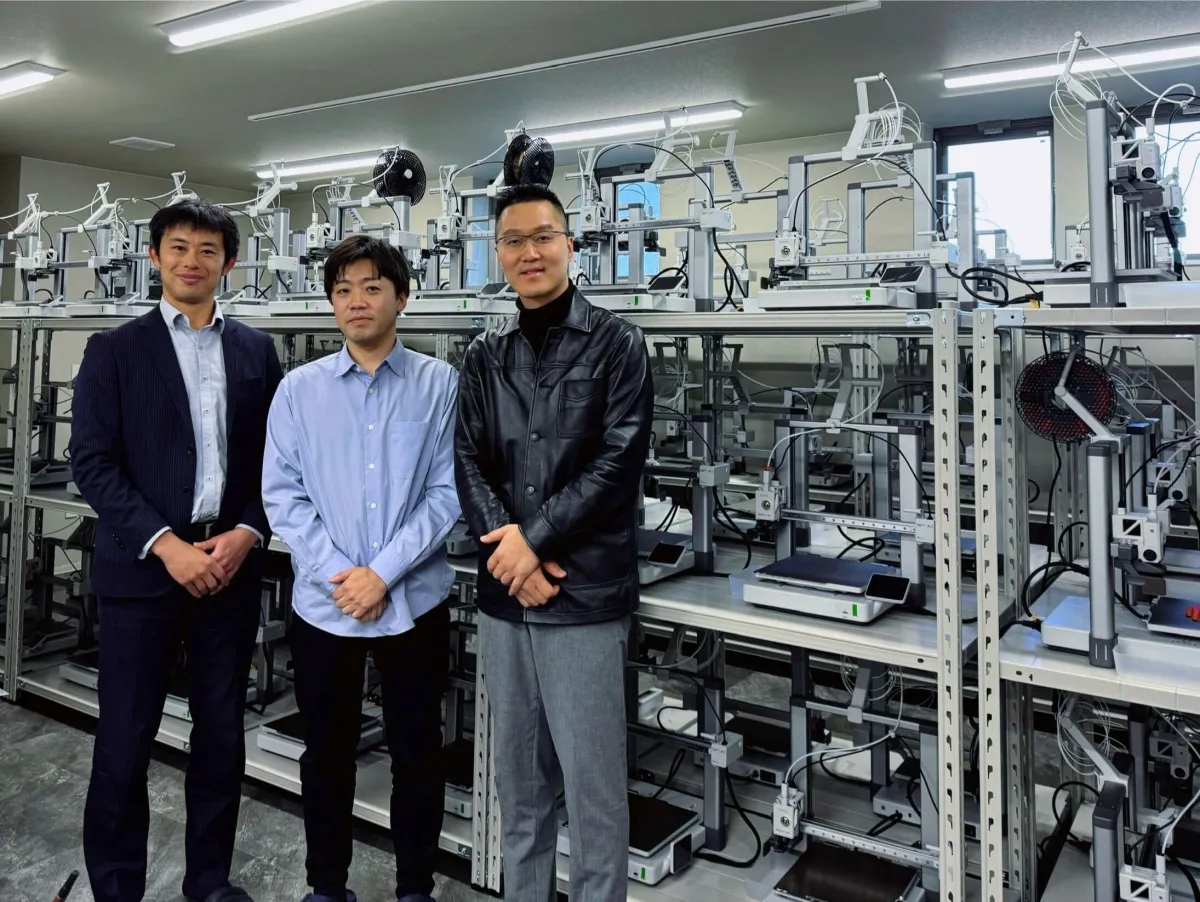

In a groundbreaking move for Japan's manufacturing landscape, APPLE TREE Inc., headquartered in Osaka, has partnered with Nagoya Kogei to launch PrintHub, the nation's first decentralized 3D printing farm. This innovative project aims to establish a flexible and responsive domestic manufacturing framework, empowering both creators and businesses alike.

A New Manufacturing Model: The 3D Printing Farm

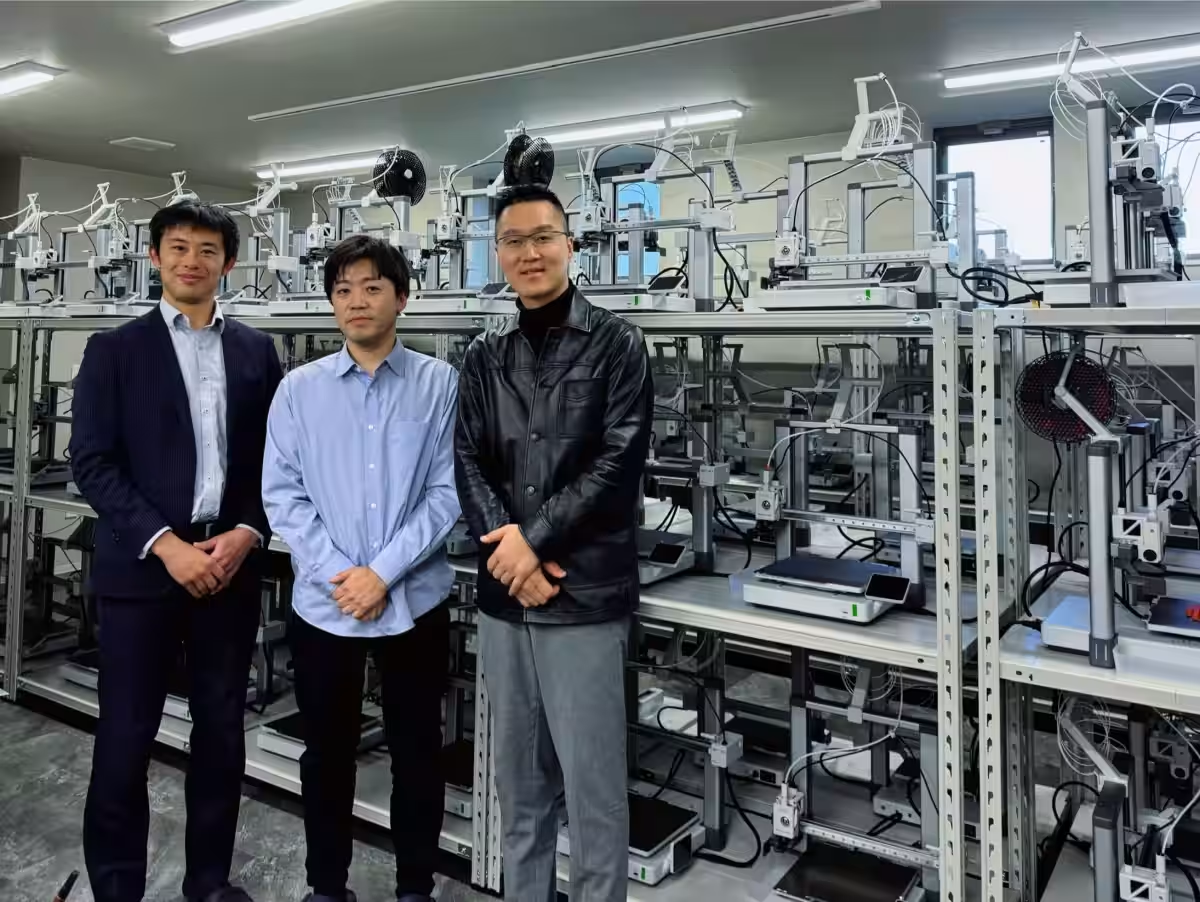

PrintHub employs a decentralized network of 3D printers that allows for on-demand production of parts and products, eliminating the need for traditional molding processes and large injection molding machines. Instead, it leverages digital data to fabricate items directly, showcasing a manufacturing model characterized by its low-cost solutions, short delivery times, and ability to accommodate small production runs. This approach has captured the attention of industries both in Japan and internationally.

The first PrintHub location will feature up to 120 high-performance Bambu Lab 3D printers, scheduled to commence full operations in spring 2026. These printers are designed for high precision and speed, enabling a significant re-evaluation of the manufacturing process, which was previously reliant on molds and large batch sizes.

By implementing a Just In Time production model, PrintHub aims to create “what is needed, when it is needed, and in the necessary quantities.” Furthermore, its design caters to operations with minimal manpower, addressing labor shortages—a prevalent issue in the manufacturing sector—by pursuing sustainable production systems.

Collaboration with Nagoya Kogei

The collaboration with Nagoya Kogei, a company specializing in traditional doll materials and known for its efforts to create sustainable filament through the recycling of automotive waste, embodies a vision for high-value, sustainable production. This partnership aims to create a comprehensive framework for filament production and 3D printing, exploring the potential for eco-friendly materials and processes.

APPLE TREE supports this initiative through its extensive knowledge of 3D printer supply and marketing, seeking to implement a decentralized and adaptable manufacturing model through PrintHub.

Supporting Creators and Businesses

PrintHub envisions multiple applications, catering to:

- - Individual Creators: Providing an outsourcing solution for event-related prototypes or small-batch production.

- - Businesses: Fulfilling prototyping needs without the need for molds, along with manufacturing repair parts and components required in short lead times.

By offering versatile options to meet the growing demand for small-scale, diverse, and rapid production, PrintHub represents a significant shift from traditional manufacturing methods.

The Future of Decentralized Manufacturing

Since the Industrial Revolution, manufacturing has predominantly favored mass production concentrated in specific locations. However, advancements in 3D printing technology make decentralized, locally-rooted production increasingly viable. PrintHub seeks to contribute to lowering logistical and environmental burdens by spreading manufacturing sites across different locales, thus revitalizing regional industries.

Envisioning a future where consumers buy data to produce items locally, PrintHub is poised to reshape the conventional paradigm of online shopping where products are shipped from distant factories.

Future Prospects

Apple Tree aims to expand the PrintHub initiative into a network of decentralized 3D printing farms across Japan over the coming years, with a mid-to-long-term vision to democratize access to manufacturing. Their goal remains to foster an environment where individuals can easily engage in production when and where they need it, driving a new era of localized manufacturing in Japan.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.