Introducing the AP Deli-O Series: Sustainable and User-Friendly Food Containers

The Launch of the AP Deli-O Series: A Sustainable Solution for Food Containers

FPCO, a leading manufacturer of food trays and containers based in Shinjuku, Tokyo, has recently unveiled its new product line, the AP Deli-O series. This innovative food container addresses the pressing needs of the market by significantly reducing plastic usage and adapting to both automated and manual sealing processes.

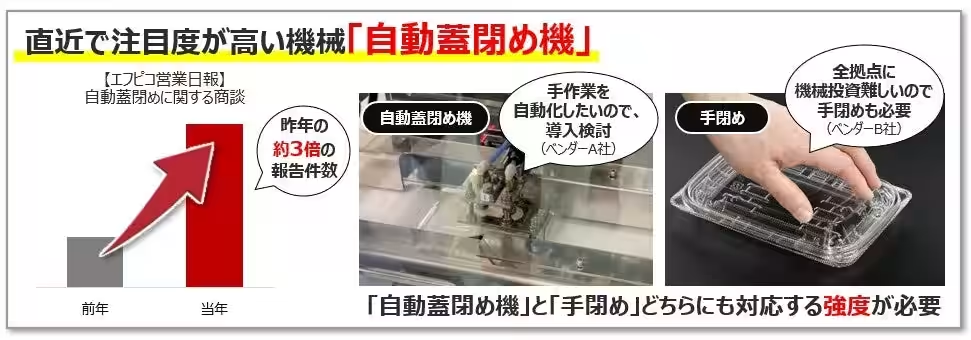

In recent years, there has been notable growth in the establishment and expansion of process centers (PC) in the food production and sales sectors. This shift has led to an increased adoption of automated sealing machines for food containers. Reports indicate that negotiations concerning automated lid sealing machines have tripled compared to the previous year, showcasing the high demand for such equipment. However, transitioning all facilities to full automation remains a challenge, and manual sealing processes continue alongside automation. Consequently, there's a growing need for food containers that can withstand both automated and manual lid sealing methods.

Moreover, there is an increasing emphasis on environmental considerations when selecting containers. Key factors influencing customer choices include the reduction of plastic usage and lightweight designs. To meet these market demands, FPCO developed the AP Deli-O series, aptly named by merging 'Deli' (for deli goods) and 'Automation,' reflecting its dual focus on mechanization and environmental consciousness while ensuring user-friendliness.

Key Features of the AP Deli-O Series

1. Significant Reduction in Plastic Usage

The AP Deli-O series is the lightest among FPCO's existing food containers, achieving a remarkable weight reduction of up to 17%. For instance, the AP Deli-O 18-13 (17) model's total weight, which includes the body and lid, has been decreased from 16.4g to 13.6g—a reduction of 2.8g.

2. Compatible with Both Automated and Manual Sealing

The AP Deli-O series features a unique structure that supports the lid and body through reinforcement ribs, offering enhanced stability. This design prevents buckling during automated sealing while also accommodating manual sealing, ensuring versatility for operators.

3. Leak Prevention Mechanism

A thorough redesign of the contact surfaces between the body and lid has led to a mechanism that successfully minimizes leakage of contents, enhancing customer satisfaction.

4. Environmentally Friendly Materials

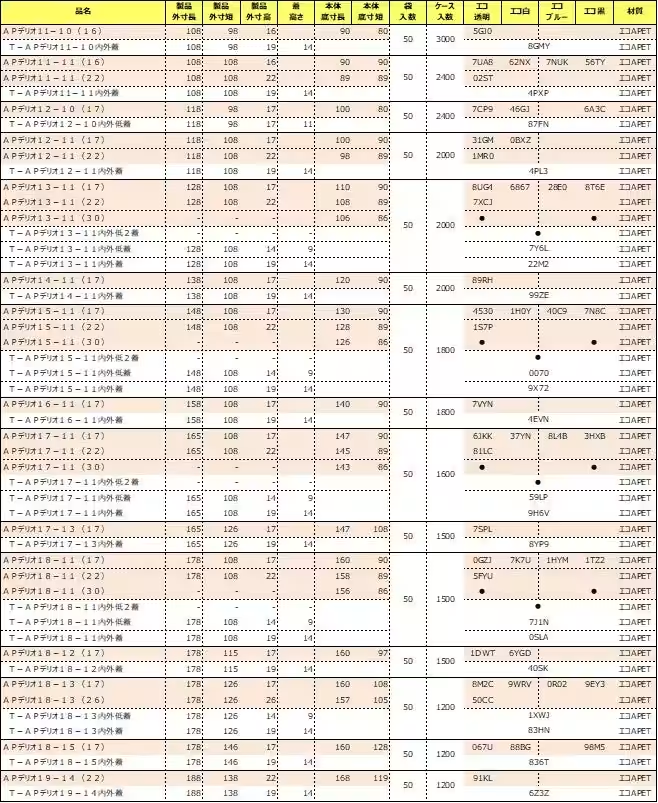

The containers are made from Eco APET, a recycled PET material. To clearly communicate their eco-friendliness, containers are marked with eco-labels and symbols indicating their use of recycled materials.

5. Diverse Size Options for Various Portions

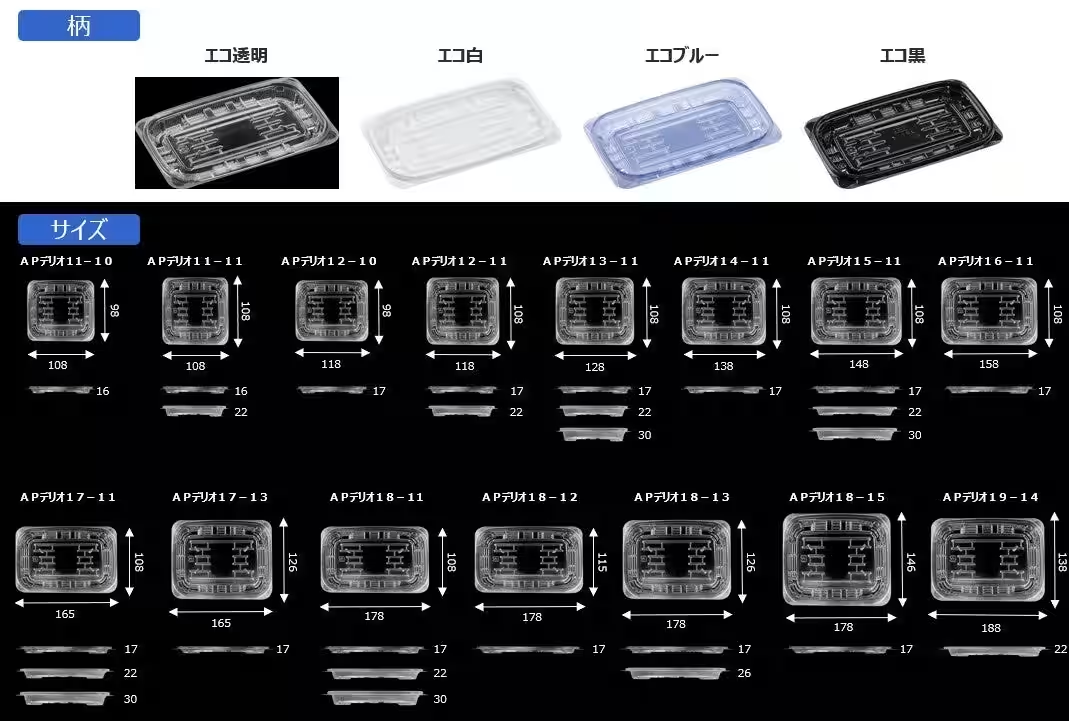

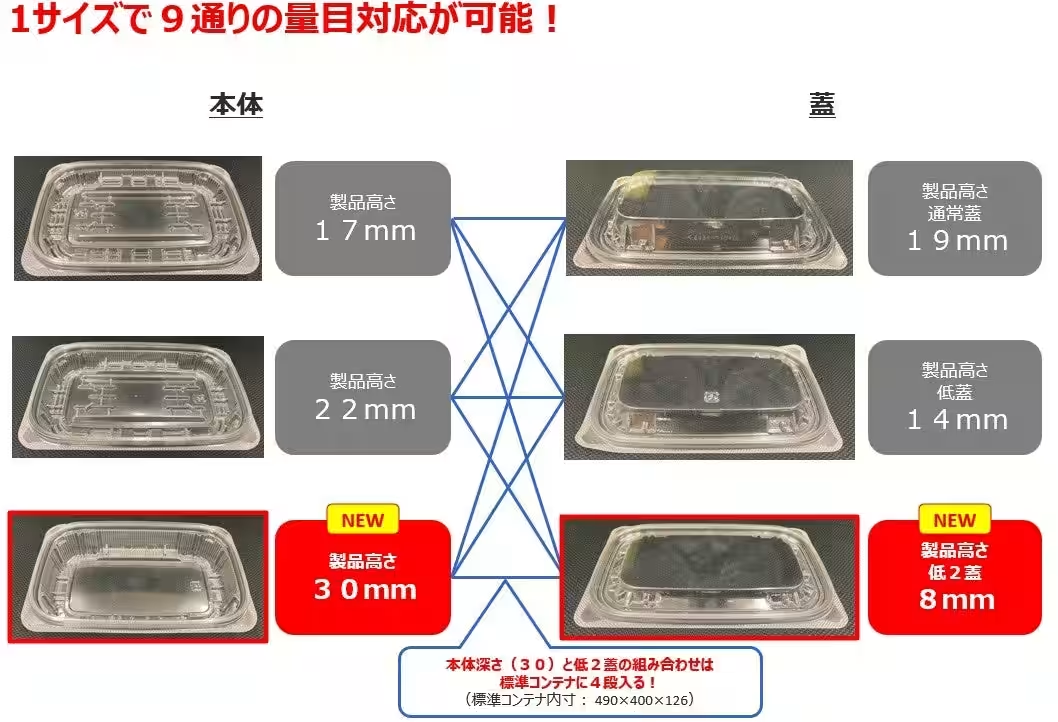

The AP Deli-O series offers a wide range of sizes and configurations, with 26 body types and 24 lid types. Sizes range from 11-10 to 19-14, allowing for combinations that enable a single body size to accommodate up to 9 different volume capacities. This flexibility meets the diverse demands of various deli products and portion sizes. Customers also have options in colors such as eco-transparent, eco-white, eco-blue, and eco-black.

In summary, the AP Deli-O series addresses the challenges of the automating deli industry while prioritizing eco-consciousness and usability. It represents a progressive step forward in packaging solutions for food manufacturers looking to meet the evolving needs of consumers in the modern market.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.