Experience Creativity Through 3D Modeling and Recycling with VOST!

Unleashing Creativity in Families with 3D and Recycling

On August 2nd, 2025, VOST Inc., located in Koto City, Tokyo, is set to host an exciting parent-child workshop that combines creativity with sustainability. This event, which will take place at Odaiba MONO, offers participants a hands-on experience in creating unique items using recycled materials, specifically focusing on 3D modeling and injection molding techniques.

Event Highlights

At this workshop, families will engage in multiple activities designed to foster creativity and learning:

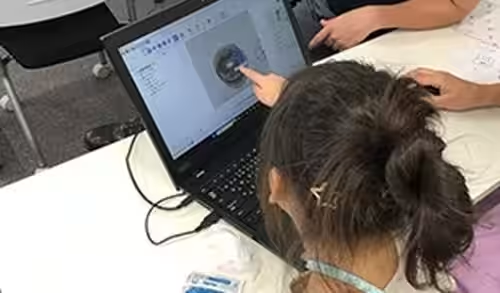

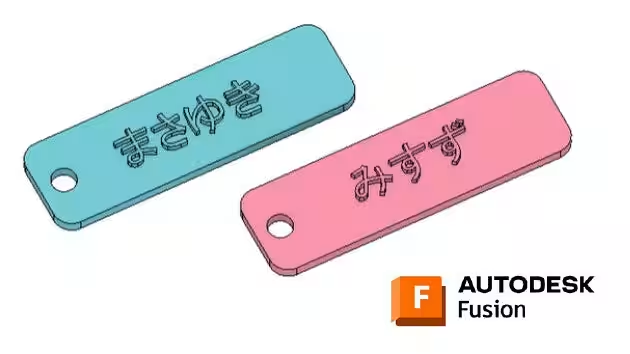

1. Understanding 3D Modeling with 3DCAD: Participants will gain insight into computer-aided design using 3DCAD programs.

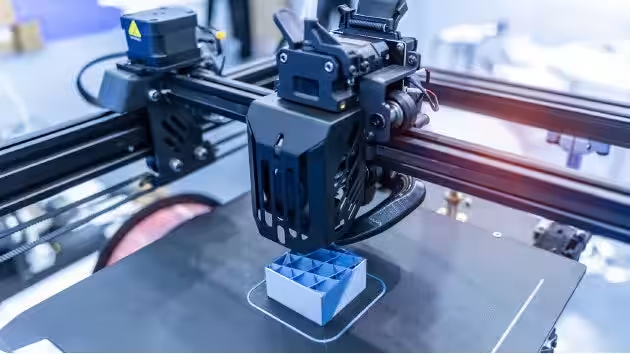

2. 3D Printing: Attendees will see their designs come to life as they print their created data using a 3D printer.

3. Crafting Lures from Bottle Caps: Using the injection molding process, families will transform recycled PET bottle caps into original lures, learning the basics of this innovative technique.

4. Data Creation and Assembly: Children will take charge of creating the data and assembling their final products, empowering them with hands-on skills and confidence.

Event Details

- - Date: Saturday, August 2, 2025 (Cancelled in case of severe weather conditions)

- - Location: Odaiba MONO, Telecom Center Building, East Tower, 14th Floor, 2-5-10 Aomi, Koto City, Tokyo

- - Target Audience: Parents and children from the 3rd grade and above (Limited to 10 families; one adult can accompany up to two children, younger siblings are welcome)

- - Participation Fee: Free

- - What to Bring: Nothing (feel free to participate hands-free)

Program Outline

- - Explore 3DCAD: Create a nameplate using Fusion 3D modeling software.

- - Watch 3D Printing in Action: See how your designs can be printed in real time.

- - Injection Molding Workshop: Understand the process of transforming shredded PET bottle caps into lures through injection molding.

- - Assembly Process: Customize your nameplate with colors and assemble the lure using various materials. Note that the lure bodies will be made from polystyrene to ensure easy assembly, as polypropylene is more challenging to work with.

- - Take Home Your Creations: All participants can take their crafted items home, fostering a sense of achievement.

Experience the Technology First Hand

Participants will gain Real-world experience by handling actual 3DCAD software and 3D printers. VOST's knowledgeable seminar instructors will guide participants through each step, making it accessible even for beginners. The goal is to ignite children's interest in technology, showcasing the endless possibilities of 3D printing and sustainable practices. Through this hands-on experience, children will cultivate thought processes that lead to innovative solutions while learning about environmentally friendly manufacturing practices.

What is Injection Molding?

Injection molding is a technology that involves melting plastic at high temperatures and injecting it into molds, allowing for the creation of products in various shapes. This technique is commonly applied in manufacturing toys, stationery, and bottle caps. Similar to cooling jelly, injection molding solidifies plastic rapidly, producing multiple identical items in a short span, which is one of its main advantages.

About VOST Inc.

VOST Inc. specializes in leveraging advanced technology for service development and technical skills training. The company strives to share complex technologies widely and correctly, aiming for innovative business creation and improvement. VOST provides a range of educational services focused on skill enhancement for professionals, including hands-on workshops to support digital transformation (DX) initiatives in companies. Additionally, VOST engages in consulting, media, human resources, and distribution services, aiming to facilitate overall support for enterprise growth and workforce development.

By introducing children to the realms of technology, art, and sustainability, VOST's event is poised to inspire the next generation of innovators and creators.

For more details about the event, please visit our website.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.