Revolutionizing Equipment Inspection Processes with AI and Collaboration Tools

Transforming Equipment Maintenance Efficiency

In a notable collaboration, NTT Docomo Business, NTT Docomo Solutions, and Toshiba have combined their technologies to improve efficiency in equipment maintenance and inspection tasks. This initiative, which took place at Toshiba's Fuchu Plant, integrated NTT Docomo Solutions' 'Plant Collaboration' and Toshiba's 'ToruMeter®'. The objective was to minimize human error and enhance operational efficiency during equipment inspection processes. The results from this project underline a commitment to advancing digital transformation (DX) in industrial environments.

The Need for Improved Inspection Processes

The manufacturing sector continually faces the challenge of maintaining aging equipment and ensuring high operational availability. In recent times, labor shortages due to an aging workforce have made efficient inspection processes more critical than ever. Traditional methods that rely heavily on manual data entry and visual inspections often lead to increased time and costs, as well as input errors that can compromise safety and reliability. To tackle these pressing issues, the collaboration explored the use of real-time data interconnectivity across multiple systems and incorporated AI-driven image recognition technology to streamline inspection procedures.

Overview of the Proof of Concept

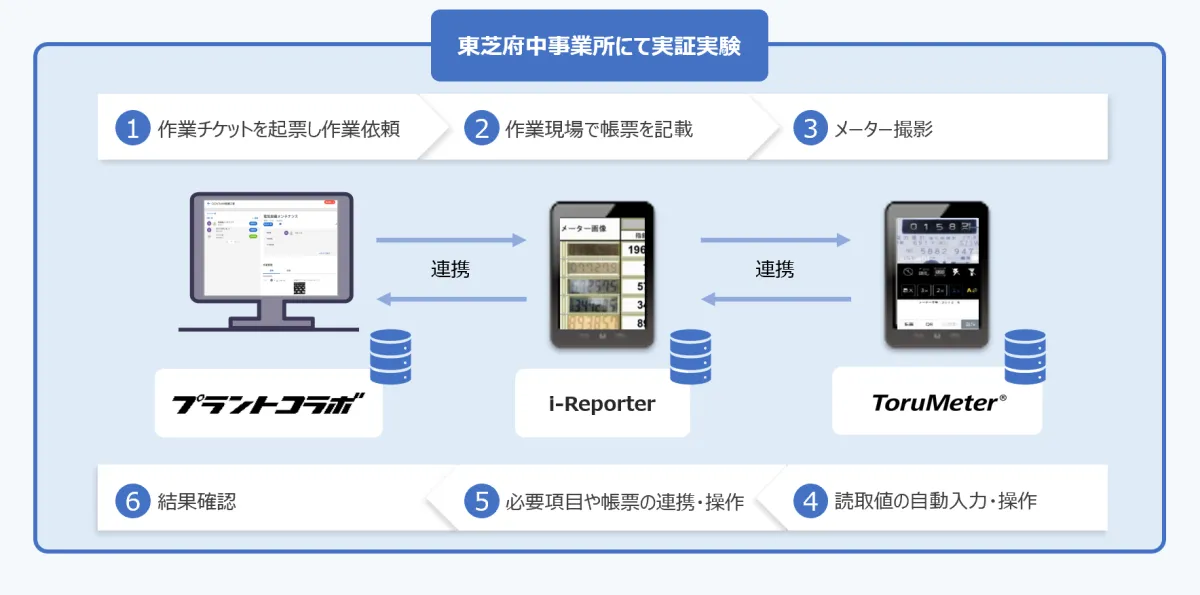

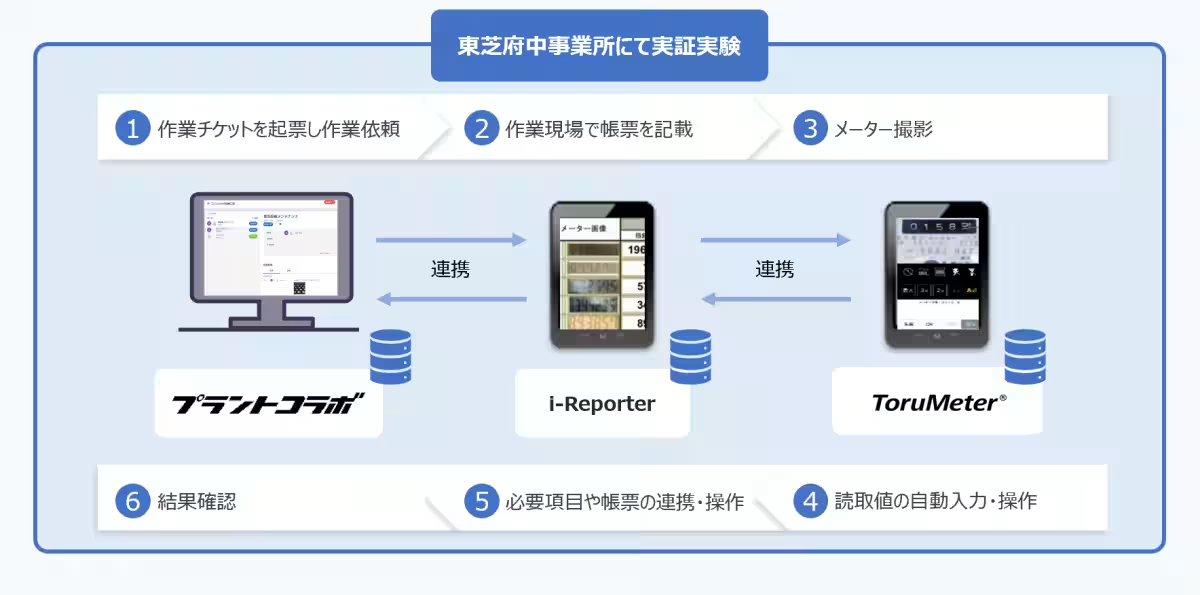

The proof of concept conducted at the Fuchu Plant simulated actual inspection scenarios, employing 'Plant Collaboration' and 'ToruMeter®' solutions linked through the electronic reporting system 'i-Reporter'. This setup allowed the instantaneous sharing of data during inspections, automating the generation of reports based on collected metrics. By capturing images of compressor meters, data was extracted through AI image processing, thus lessening the need for traditional visual checks.

The outcomes confirmed that the systems could exchange information instantly, allowing remote managers to access real-time reports and status updates without being physically present. Furthermore, the innovative approach enabled inspections to be carried out by a single technician instead of two, yielding significant cost-saving benefits.

Roles of Each Partner Company

- - NTT Docomo Business: Responsible for the sales of 'Plant Collaboration' and 'ToruMeter®'.

- - NTT Docomo Solutions: Provided and supported the implementation and operation of 'Plant Collaboration'.

- - Toshiba: Offered 'ToruMeter®' alongside implementation and operational support.

Future Prospects

Moving forward, NTT Docomo Business, NTT Docomo Solutions, and Toshiba plan to market the combined offerings of 'Plant Collaboration' and 'ToruMeter®' primarily to factories and plants with operational requirements. By tailoring solutions to clients' specific needs and combining various systems, the partnership aims to foster enhanced efficiency and reduced labor in inspection operations, contributing significantly to the creation of well-being-focused workplaces.

This collaborative model of integrating 'Plant Collaboration' with 'ToruMeter®' will be showcased from July 23 to 25, 2025, at the Maintenance Resilience Tokyo 2025 event, exemplifying the advancement of real-time digital solutions in industrial settings.

Visit us at Booths East Hall 6-C09 to explore more about our revolutionary approaches to equipment maintenance and inspection.

Topics Business Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.