Atlas Copco Launches Air Quality Monitor for Enhanced Manufacturing Standards in Japan

Atlas Copco Launches Air Quality Monitor in Japan

On May 7, Atlas Copco, a leading global provider of sustainable productivity solutions headquartered in Tokyo, officially introduced the Air Quality Monitor (AQM) for domestic sales. This innovative service aims to enhance the visibility of air quality in manufacturing environments by adhering to the ISO8573-1 standard, allowing for real-time monitoring of particle levels, oil content, and dew point, significantly aiding quality assurance, maintenance, and environmental measures.

The Importance of Air Quality in Manufacturing

In the manufacturing sector, the cleanliness of compressed air is a critical factor that directly impacts product quality and the lifespan of machinery. Traditionally, companies relied on periodic inspections or visual assessments to gauge air quality, making real-time monitoring a challenging task. The newly launched AQM empowers manufacturing facilities to overcome this limitation.

Comprehensive Monitoring with AQM

The Air Quality Monitor offers an all-in-one solution, measuring and recording three key parameters continuously:

- - Solid Particle Concentration (0.1–5µm)

- - Dew Point (-100 to +20°C)

- - Oil Vapor Concentration (0.001–5mg/m³)

These metrics comply with the ISO8573-1 standard, facilitating the visualization of quality benchmarks and proof of reliability to clients.

Advantages of Implementing AQM

Businesses that incorporate the AQM will enjoy several significant benefits:

- - Real-time Monitoring: Prevents contamination by unwanted substances and condensation through continuous monitoring.

- - SMARTLINK Integration: This feature allows for cloud-based monitoring and trend analysis remotely, enhancing operational efficiency.

- - Alert System: Immediate notifications during anomaly detections, ensuring prompt responses to potential issues.

- - Durable Design: Built to last with IP54 specifications, the compact wall-mounted design saves space while maximizing functionality.

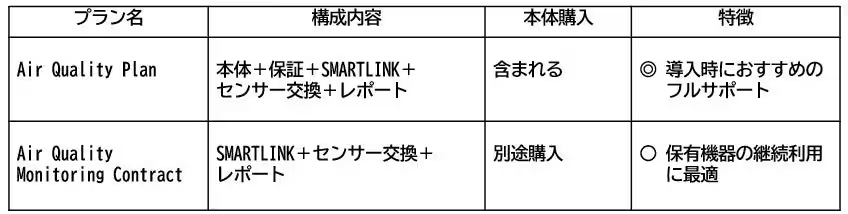

Maintenance Packages for Peace of Mind

To ensure that users can confidently operate the AQM post-installation, Atlas Copco provides two comprehensive contract plans, including maintenance services.

Understanding ISO 8573-1

ISO 8573-1 is an international standard that classifies the purity of compressed air based on the quantity of solid particles, moisture (dew point), and oil content. The air quality directly influences product reliability and equipment safety. The AQM delivers continuous monitoring of these critical factors, providing measurable insights into the air quality within manufacturing facilities.

Primary Applications and Benefits

The AQM is applicable in various sectors, including:

- - Electronics & Semiconductors: Enhances yield by preventing contamination from foreign particles and moisture/oil content.

- - Food & Pharmaceuticals: Reduces product contamination risks while ensuring compliance with HACCP and GMP standards.

- - Automotive Parts & Coating Lines: Stabilizes finishing quality by preventing paint defects and mechanical issues.

- - Clean Rooms: Assists in managing particles, moisture, and oil for compliance with environmental audits and evaluations.

Upcoming Webinar - Free Session on AQM

Atlas Copco is hosting a free webinar on June 24, 2025, from 1:00 PM to 1:40 PM, to delve into detailed product specifications, data integration with SmartLink, and the implementation process of the Air Quality Monitor. Pre-registration is required for participation.

Pricing and Installation Process

Pricing varies based on equipment configuration and installation scale, with the following process outlined:

1. Initial consultation and needs assessment.

2. Pre-diagnosis of air quality via onsite measurements.

3. If necessary, air cleanliness improvement measures (e.g., filter installations).

4. Proposal of the optimal installation plan.

5. Setup of the device and initial configurations.

6. Commencement of operation, including remote monitoring capabilities.

Contact Information

For inquiries, please reach out to Atlas Copco’s Compressor Division at:

Email: [email protected]

Explore More

About Atlas Copco Group

Founded in 1873, Atlas Copco has been transforming industrial ideas into valuable business benefits. With a presence in over 180 countries and projected revenue of 176 BSEK in 2024, Atlas Copco continues to innovate by understanding customer needs and providing future-focused solutions. The company is based in Stockholm, Sweden, with approximately 55,000 employees worldwide. For more information, visit www.atlascopco.com.

Topics Business Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.