Three Companies Collaborate to Innovate Logistics in Japan's Supply Chain

Transforming Logistics: A Sustainable Collaboration

In a pioneering effort to enhance efficiency within the logistics sector, three major players—Haleon Japan, Rohto Pharmaceutical, and Milbon—are teaming up to launch a joint delivery service by August 2025. With the growing need for sustainable supply chains and the challenges of labor shortages and extended working hours in the logistics industry, this collaboration aims to collectively address these pressing issues.

Background of the Initiative

The logistics industry is grappling with significant challenges, including chronic labor shortages and long hours for drivers, raising questions about sustainability. Haleon Japan has been proactive in seeking solutions to these challenges, particularly by optimizing loading methods to improve transportation efficiency. However, despite these efforts, issues such as excess space during loading due to storage efficiency and product specifications remained obstacles.

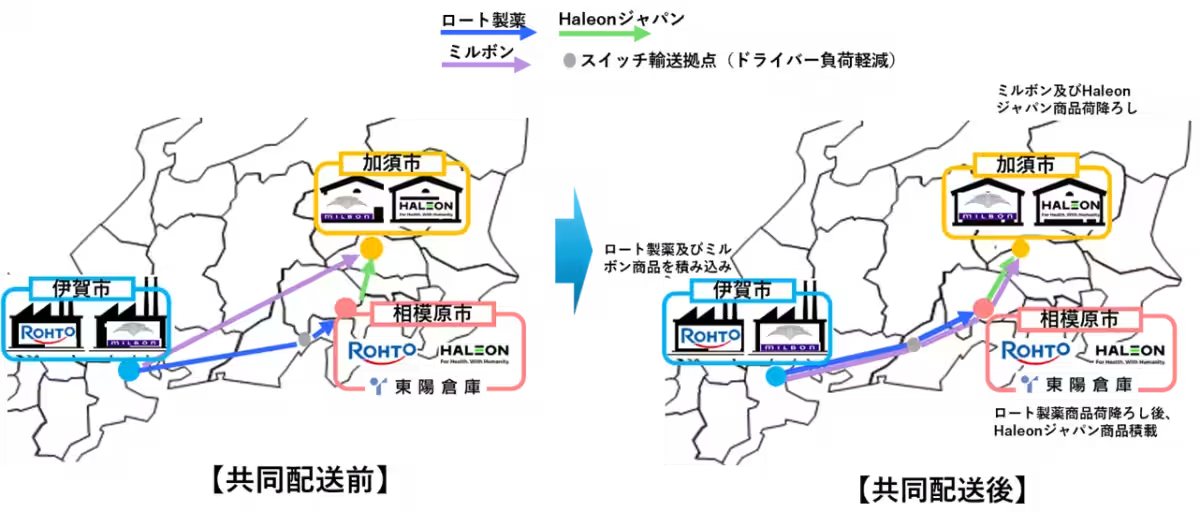

Recognizing a commonality in their delivery routes, the three companies are creating a joint transportation system that will maximize loading efficiency. This innovative approach looks to reduce CO2 emissions and enhance the working conditions for drivers while contributing to the sustainability of all stakeholders in the supply chain.

Challenges and Solutions by Company

- - Haleon Japan: The company, headquartered in Tokyo, has been contracting production to facilities in Sagamihara, Kanagawa. Transportation from the manufacturing site to their logistics hub in Kazo, Saitama, has led to underutilization of space due to the specific product size.

- - Rohto Pharmaceutical: Operating from their Ueno Techno Center in Iga, Mie Prefecture, Rohto has faced similar issues regarding loading efficiency and excess space when transporting products to the warehouse in Sagamihara.

- - Milbon: From their Yume-ga-oka factory, also in Iga, Mie, the company has struggled with loading limitations and risks of over-supply during transportation to their Kazo warehouse.

To tackle these issues, the companies have developed a collaborative delivery scheme. This includes selecting suitable products for joint transportation, verifying loading techniques, and conducting quality tests to meet various constraints such as pallet sizes and safety requirements. By streamlining the connection between manufacturing sites and warehouses using a relay system, they aim to maximize loading efficiency and ensure smooth operations for long-distance transport without overloading drivers.

Expected Outcomes of the Collaboration

The collaborative delivery, taking place weekly, is anticipated to yield remarkable improvements:

- - Loading Efficiency: A projected increase of 13.7%, raising the average from 66.5% to 75.6%.

- - Transport Efficiency: A reduction of 102 trucks annually (67.1%).

- - Distance: A significant cut of 15,428 km annually (38.6%).

- - CO2 Emission Reduction: An estimated cut of 13.3 tons annually (32.8%).

- - Additionally, this collaboration is expected to result in an 18.4% decrease in transportation costs and a 19.2% improvement in single-operation costs, contributing positively to driver employment conditions.

Future Prospects

As the joint delivery system begins with a monthly schedule, the aim is to increase to a weekly schedule for regular and stable operations. Success stories and insights gained from this collaboration will be utilized to expand partnerships with other companies. Emphasizing digital transformation in logistics, they plan to automate scheduling to optimize loading rates and improve efficiency further.

Furthermore, the objective is to extend this initiative across various areas of the supply chain, including upstream logistics for raw materials and downstream for product distribution, significantly contributing to overall sustainability within the supply chain and addressing societal and environmental challenges.

About the Companies Involved

- - Haleon Japan: This arm of Haleon, a global leader in consumer health, operates in Japan with a commitment to delivering health solutions rooted in trust and science. They offer various consumer health products, including oral health and OTC medications.

- - Rohto Pharmaceutical’s Ueno Techno Center: Serving as a core manufacturing facility since 1999, this center is responsible for key products like eye drops and skincare solutions, emphasizing quality management and logistics.

- - Milbon’s Yume-ga-oka Factory: Strategically located for efficient logistics, this facility has a dual focus on production management and technical development, ensuring timely responses to dynamic hair care market needs.

Through this innovative partnership, the companies are taking significant steps toward reshaping logistics in Japan, demonstrating how collaboration can lead to substantial improvements in efficiency and sustainability within the supply chain.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.