Somic Ishikawa Implements 'MISUMI Floow' to Enhance Efficiency

Introduction

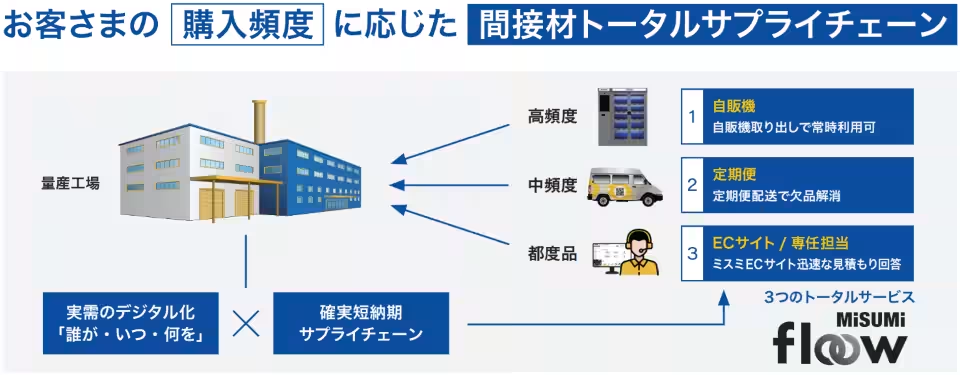

In an impressive move towards operational efficiency, Somic Ishikawa, a leader in automotive component manufacturing based in Hamamatsu, Shizuoka, has adopted the MISUMI Floow system. This innovative indirect material total cost reduction service, provided by MISUMI Group, aims to streamline the procurement processes particularly in the management of consumables, thereby enhancing productivity in the manufacturing environment.

Background

Somic Ishikawa is renowned for its dominance in the production of suspension components, specifically ball joints, which hold a significant share in the domestic market. However, the company faced challenges with their existing kanban management system used for operational consumables like gloves. This system led to delays in order placements and an increased risk of stockouts due to discrepancies in inventory management. Recognizing the inefficiencies shared between the production line and administrative departments, the decision was made to implement MISUMI Floow, a service previously found beneficial in their Chinese subsidiary.

Implementation of MISUMI Floow

The introduction of MISUMI Floow has revolutionized the way Somic Ishikawa manages its inventory, especially for frequently used gloves. By installing vending machines within the factory and utilizing a system for automated replenishment managed by MISUMI, they effectively eliminated the worries around order omissions and stock shortages. This system not only mitigated procurement hassles but also drastically reduced manual processes involved in sorting and disposing of delivery boxes, significantly easing the burden on both the production and management teams.

A dedicated representative from MISUMI provides support for tailored inventory management, adjusting shelf placements based on consumption trends, and promptly addressing requests for additional items. The visibility into usage has fostered a heightened cost-conscious mindset among employees, leading to a remarkable 25% reduction in costs compared to previous figures by the four-month mark post-implementation. Future plans include expanding the system to cover auxiliary materials and cutting tools across additional factories.

Impacts on Somic Ishikawa

The deployment of MISUMI Floow has led to a notable reduction in psychological stress for both the operational and management sectors, as it alleviated fears concerning stockouts through streamlined inventory processes. Employees can now retrieve just the necessary amounts at the right time without fretting about delivery timelines. Furthermore, the service’s usage tracking—enhanced by face recognition technology to identify users and monitor their consumption—has provided clarity on who uses what and when, thereby boosting the awareness of cost management practices on the ground.

Moreover, the elimination of post-delivery sorting and box disposal, which previously consumed about an hour daily from workdays, has improved workflow efficiency. Employees have expressed that the project has led to a more organized and clean workspace, reflecting positively on their work environment and overall morale.

Following the integration, the MISUMI representative has actively engaged with Somic Ishikawa to propose adjustments according to usage trends and to manage requests for items not currently available through vending machines. By maintaining collaboration, both entities aim to foster continuous improvements in procurement efficiency and cost management.

Testimonials from Somic Ishikawa

Takahiro Suda, Head of the Tsuru Management Division, remarked on the previously existing inefficiencies: “The implementation has refined our working environment, and the visibility into usage has significantly enhanced our management confidence. Moving forward, we plan to integrate feedback from the production floor to create an even more conducive work environment.”

Tetsuya Okubo, Head of the Tsuru Management Division's Engineering Office, noted, “If we could also manage auxiliary materials through vending machines, it would enhance convenience even further. Particularly, managing cutting tools is critical as shortages directly impact the production line.”

From the domestic procurement team, Shun-zheng Yang reflected on discovering MISUMI Floow during a webinar: “I introduced it to our Chinese subsidiary where it was embraced as a much-needed service. It significantly improved inventory management efficiency, paving the way for our own implementation in Japan.”

Conclusion

MISUMI Floow is not merely about inventory management; it represents a significant shift toward digital transformation in manufacturing. By incorporating advanced technologies to enable a streamlined supply process, Somic Ishikawa stands at the forefront of operational excellence in the automotive parts industry. As cost reductions continue, the broader deployment of this service could redefine traditional procurement models and influence the future of manufacturing.

For more details, visit the MISUMI Floow service site or check out the customer testimonials.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.