Rising Production of Automated Stages to Meet Data Center Demand

Rising Production of Automated Stages to Meet Data Center Demand

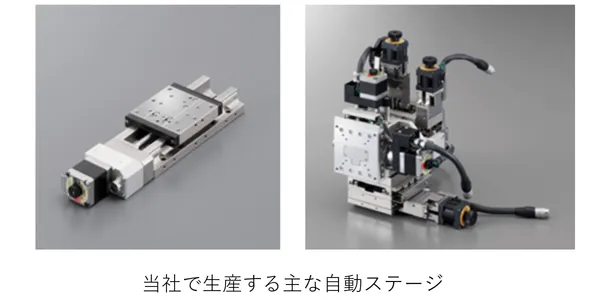

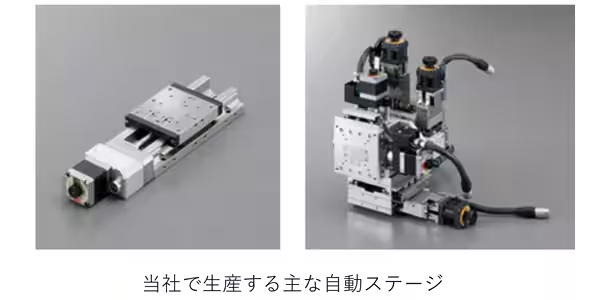

On January 29, 2026, Mitsumi Group Ltd., headquartered in Chiyoda, Tokyo, announced a significant increase in the production of automated stages tailored for the data center market. This expansion is fueled by the global proliferation of generative AI, which has spurred an unprecedented demand for data processing capabilities in data centers.

To support this increase in output, Mitsumi Group plans to invest approximately ¥2 billion in its manufacturing bases located in China and Vietnam, thereby doubling its supply capacity. This strategic move aligns with the company's ongoing commitment to responding effectively to the growing AI-driven demands in the manufacturing sector.

The Background of the Investment

The rise of generative AI has led to a global surge in demand for data centers as they become the backbone for processing the massive amounts of data generated. According to the Ministry of Internal Affairs and Communications' 2024 Information and Communications White Paper, the data center market is expected to reach a staggering $416.1 billion in 2024 and grow even further to $624.1 billion by 2029. Nearly half of this projection is tied to equipment and services related to network infrastructure.

A noteworthy illustration of this demand is the significant increase in the number of optical transceivers used in servers, which has risen dramatically compared to the pre-AI era. Consequently, the need for automated stages—integrated into the manufacturing equipment for optical transceivers—has also surged, prompting Mitsumi to ramp up production capabilities to meet customer orders with swift turnaround times. This proactive expansion aims to enhance supply readiness in a rapidly growing market.

Overview of the Production Increase

The strategic investment of approximately ¥2 billion will be allocated for the mass production of automated stages at Mitsumi's manufacturing facilities in China and Vietnam, facilitating a doubling of their output capacity.

Mitsumi's 'Digital Model Shift' and the Future of Manufacturing

Mitsumi Group has been transforming manufacturing processes through digital technologies. In 2000, the company pioneered an online ordering service in the industry, enabling the complete selection and ordering of parts via the web. Since then, innovative services like 'meviy,' which allows AI to provide automated estimates from 3D data, have positively impacted productivity across various sectors.

Mitsumi places 'Digital Model Shift' at the core of its growth strategy, aiming to bring forward new value to its customers with the concepts of 'Toku Mitsumi' and 'Raku Mitsumi.' By digitally transforming design and procurement processes, the company aims to drastically improve productivity in design and production while simultaneously offering cost-saving solutions. This shift allows customers to focus on more creative work by alleviating the burden of tedious daily tasks.

Mitsumi is dedicated to transforming each individual's time into a valuable resource and fostering sustainable growth together with its customers.

About Mitsumi

As a provider of essential mechanical components, tools, and consumable items, Mitsumi serves over 323,000 companies globally as of March 2025. The company operates under a unique business model that integrates manufacturing capabilities with the distribution of third-party brands, thereby contributing to achieving 'global assured short delivery times' and enhancing convenience for its customers.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.