Transforming Office Spaces: The Rise of Horizontal Recycling in Japan

The Evolution of Office Renovation in Japan

In the realm of office renovations, a significant change is afoot in Japan. The Refineverse Group, headquartered in Chiyoda, Tokyo, has recently launched a dedicated webpage highlighting the innovative concept of horizontal recycling for discarded carpet tiles. As of October 27, this initiative aims to educate and encourage businesses to adopt circular recycling practices during their facility upgrades. This new approach addresses the need for sustainable operations in modern workspaces. Visit their special landing page here to learn more.

What is Horizontal Recycling for Carpet Tiles?

Carpet tiles, commonly utilized in offices and commercial spaces, are made from complex materials where the fiber layer is integrated with a resin layer. This combination has historically made it challenging to recycle, leading to a significant volume of these products ending up in landfills. Over the past two decades, Refineverse has taken on the challenge of this issue, establishing a revolutionary technique for horizontal recycling. This method allows discarded carpet tiles to be transformed back into raw material, facilitating approximately 60 million square meters (around 300,000 tons) of material to be repurposed effectively.

Currently, there is a robust movement toward horizontal recycling across the Tokyo metropolitan area, with around 50% of carpet tiles being efficiently recycled, based on the company's own research. This initiative signifies a critical shift in waste management, moving from traditional disposal methods to more sustainable practices.

How Horizontal Recycling Works

The process begins with the collection of discarded carpet tiles, which is carried out by the Group’s subsidiary, GMS, and industrial waste disposal businesses. In Yachiyo City, Chiba Prefecture, discarded tiles are transported to the Refineverse Chiba Factory, as well as the Refineverse Innovation Center (RIVIC) in Futtsu City. Here, they undergo a recycling process to become a new raw material known as 'Refine Powder'. This powder is then used by various carpet tile manufacturers as the primary ingredient for creating new recycled carpet tiles.

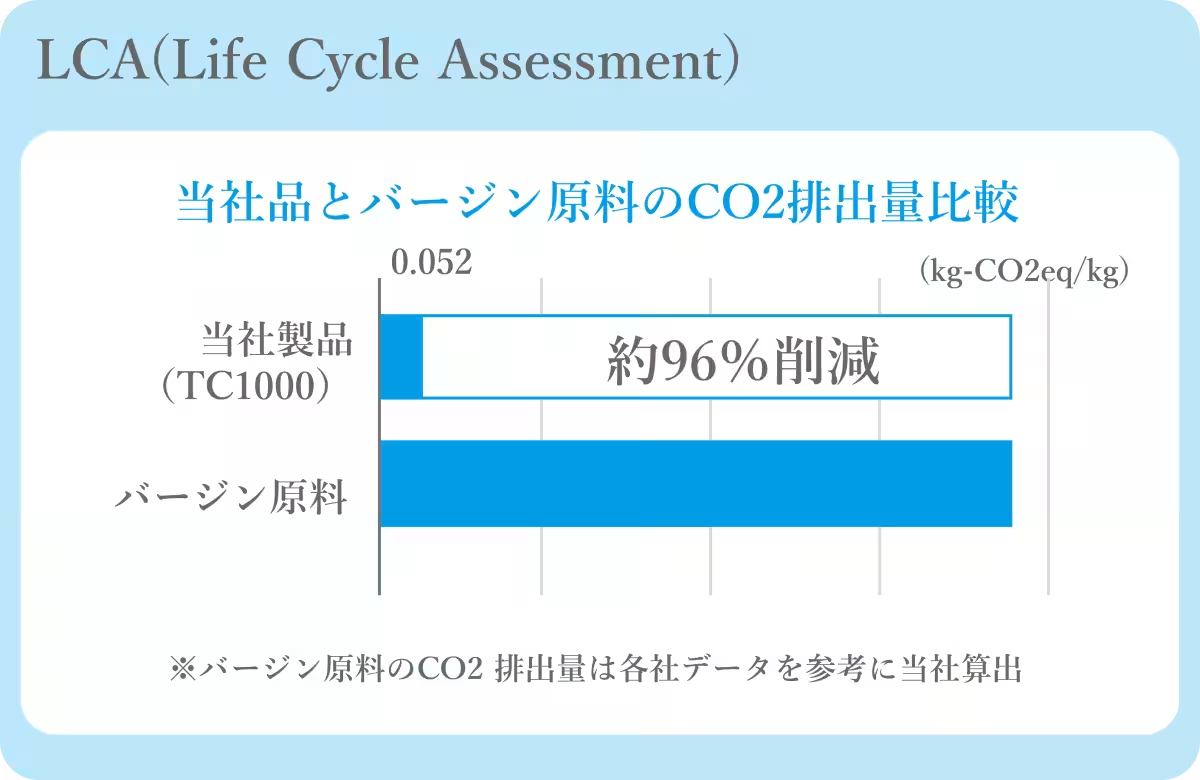

The environmental benefits of using Refine Powder are substantial. Compared to conventional new materials, it boasts an impressive 96% reduction in CO₂ emissions, making it an attractive option for many companies aiming to develop eco-friendly office environments. As businesses increasingly prioritize sustainability, the adoption of Refine Powder is on the rise.

Overview of Refineverse

The mission of Refineverse is simple yet profound: "Connecting future wealth through innovative perspectives and technologies." Having practiced circular economy principles for over 20 years, the company focuses on the recycling and development of various materials. Their operations extend beyond carpet tile recycling; they also recuperate materials from discarded fishing nets and airbags to produce high-quality recycled nylon pellets called 'REAMIDE'.

In 2023, Refineverse embarked on a new venture by developing an innovative bio-material named 'ReFEZER', derived from bird feathers, illustrating their ongoing commitment to innovation and sustainability. This breadth of operations reflects their dedication to expanding business impact, promoting a circular economy, and securing a sustainable future for our society.

For more details on the carpet recycling initiative, visit the Carpet Tile Recycling Landing Page.

More about Refineverse Group

Website: Refineverse Website

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.