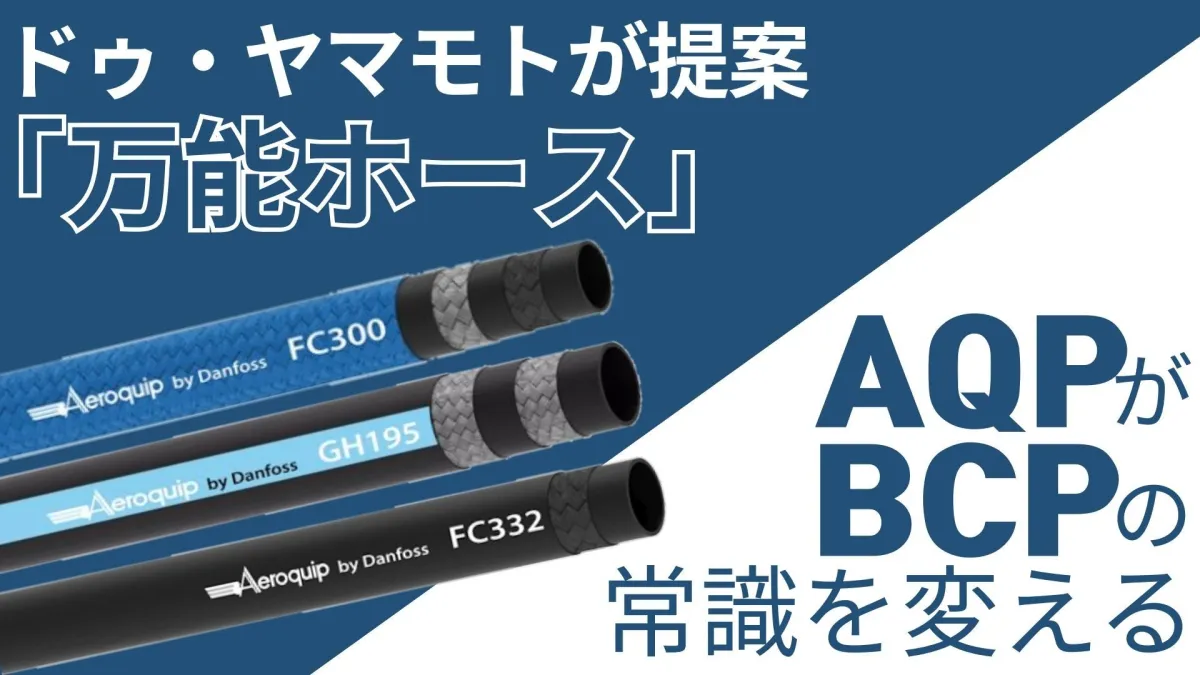

Revolutionizing BCP Strategies with Do Yamamoto's Versatile Hose Solutions

Rethinking BCP Measures with Do Yamamoto's Innovative Hose Solutions

In today's industrial landscape, unexpected equipment failures can halt production lines instantly, leading to significant financial losses. Among the often overlooked elements in business continuity planning (BCP) is the risk of hose deterioration or damage. Do Yamamoto, a leading industrial hose supplier, introduces a new paradigm with its proposal of a "no-prepare BCP" using the highly versatile Aeroquip (AQP) hoses from Danfoss (formerly Eaton) along with reusable fittings (AMR/LAR). This approach moves beyond the traditional method of stockpiling multiple types of hoses to prevent risks.

Understanding the Risks of Production Line Halts

The demands of modern industries necessitate continuous operation, where a single malfunctioning hose can bring an entire production line to a standstill. This not only leads to delayed deliveries and damaged reputations but can also result in losses amounting to millions of yen—sometimes even tens of millions. Conventional BCP strategies typically involve keeping vast inventories of various hose types. However, this can lead to increased management costs, space constraints, and the nightmare of not finding the needed component quickly when it’s critical.

Aeroquip Hoses: Versatile Solutions for Every Need

Do Yamamoto's Aeroquip (AQP) hoses are engineered to tackle these BCP challenges with exceptional versatility.

- - Multi-fluid Compatibility: One hose can handle a wide array of fluids including hydraulic oil, gasoline, water, air, crude oil, fuel oil, and lubricants. This capability ensures that, in urgent situations, there’s no need to ponder which hose to use, as one AQP hose suffices. Reducing the variety of spare parts leads to simplified inventory management and cost savings.

- - High-Temperature Resistance: In environments where high temperatures are prevalent, hoses can heat up excessively, posing burn risks to workers and affecting surrounding equipment, not to mention leading to quick hose degradation. The AQP hose boasts remarkable heat resistance, handling internal fluid and external temperatures up to +150℃. Tests show that the FC300 hose remains unaffected even after being exposed to a +150℃ environment for an extended period.

- - Durability Test Success: To prevent sudden failures, hoses must be durable, and the FC300 hose has cleared over one million impulse tests at a continuous fluid temperature of +150℃, proving reliable even in harsh conditions. Its excellent resistance to oxidation, ozone, and various chemicals makes it suitable for delicate tasks like the removal and replacement of PCB-containing equipment.

Streamlining BCP: In-House Repairs for Faster Recovery

The standout feature of Do Yamamoto's BCP solutions is that clients can perform rapid in-house repairs during emergencies.

- - On-Site Fitting Installation: The AQP hoses can be paired with AMR (high-pressure crimp fittings) and LAR (medium and low-pressure fittings), allowing teams to assemble hose fittings on-site using only the necessary hoses and fittings.

- - Minimizing Downtime: This means no waiting for external service providers, drastically reducing recovery times and minimizing downtime for production lines. This capability offers a robust advantage in business continuity.

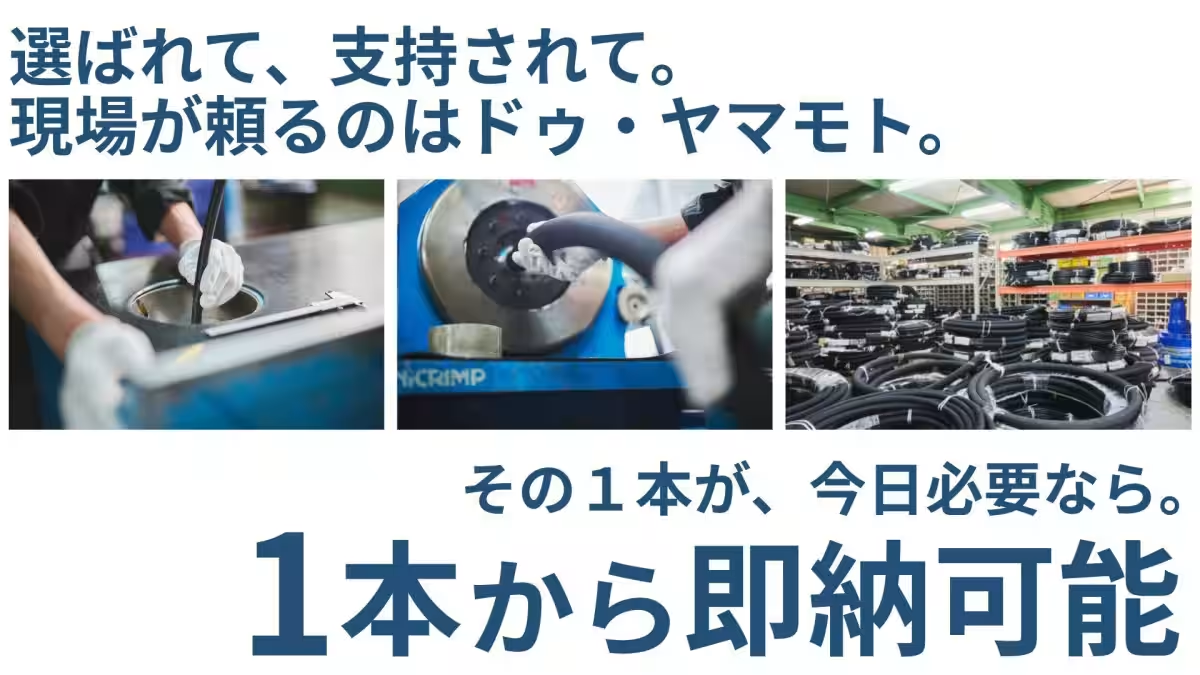

Ensuring Readiness with Immediate Assembly Availability

Even with versatile hoses and repair abilities, availability during critical moments is essential. Do Yamamoto has established a solid support system in collaboration with Danfoss and Bridgestone as a recognized factory.

- - Extensive Inventory: The company maintains a stockpile of around 100,000 meters of industrial hoses to meet diverse customer needs promptly.

- - Quality Assembly Techniques: Experienced staff apply their expertise to process and provide optimal hose assemblies with high quality.

- - Rapid Delivery: During emergencies, even processing a single hose for rapid delivery helps minimize equipment downtime and robustly supports business continuity.

Transition from Traditional to Modern BCP Approaches

Do Yamamoto's proposed BCP model shifts from the old paradigm of stocking various hose types to a more efficient one that incorporates versatile hoses, reliable supply chains, and on-the-spot repair capabilities. This transition allows businesses to reduce costs while building a solid framework for managing unforeseen risks effectively.

Moving forward, Do Yamamoto is committed to enhancing productivity and risk management for its customers by providing high-quality products and optimal solutions.

About Do Yamamoto Inc.

Founded in 1959, Do Yamamoto Inc. specializes in industrial hoses. As a Bridgestone-certified factory, it boasts one of the industry’s leading inventory volumes and extensive experience in hose sales and processing, dedicated to solving customer challenges.

Company Overview

- - Company Name: Do Yamamoto Inc.

- - Certifications: Bridgestone Certified Factory / Aeroquip Certified Factory

- - Products: High-pressure hoses, industrial rubber products, plastic products, and other industrial materials and accessories.

- - Corporate Website: Do Yamamoto

- - Service Site: Hose Search

Topics Business Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.