NSK Warner Develops World's Leading Conductive Bypass Plate with High Conductivity and Space Efficiency

NSK Warner's Innovative Conductive Bypass Plate

In a groundbreaking development for the automotive industry, NSK Warner, a subsidiary of NSK Ltd., has introduced a conductive bypass plate that meets global standards for both high conductivity and space efficiency. With plans to launch this innovative product in the market by 2026 and target annual sales of 1 billion yen by 2027, it's poised to significantly impact electric vehicle technology.

1. Background of Development

The ongoing electrification of vehicles has brought to light several challenges, particularly around the driving range of electric vehicles (EVs). To tackle these issues, electric motors, such as those used in eAxle systems, are transitioning towards higher voltage operations that allow enhancements in efficiency and reductions in charging times. However, this trend towards high voltage creates new challenges. One such problem is the occurrence of electric corrosion in bearings caused by the voltage and current generated around them. This can lead to unusual noises and even cause vehicles to become inoperable.

Additionally, in vehicles with increasingly complex electrical circuits, the high voltages create electromagnetic noise, which can lead to malfunctions in onboard systems, including radios. Consequently, the market has seen an increased demand for conductive components capable of dissipating electric charges to address issues of electric corrosion and electromagnetic compatibility (EMC).

As manufacturers prioritize extending the driving range of EVs, they are also focused on reducing the size and weight of drive components. Therefore, there is a pressing need for conductive products that are both highly conductive and space-efficient, leading to the development of this new conductive bypass plate.

2. Features and Benefits of the Product

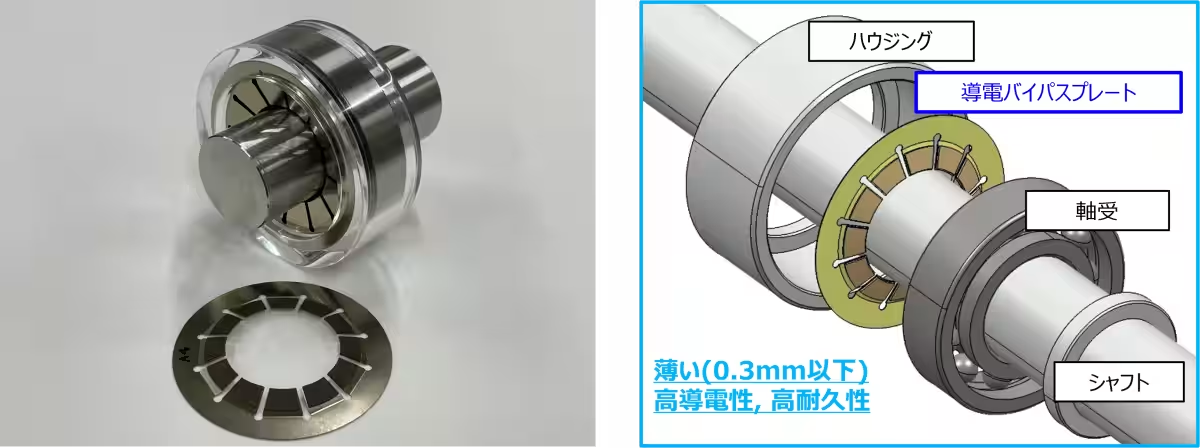

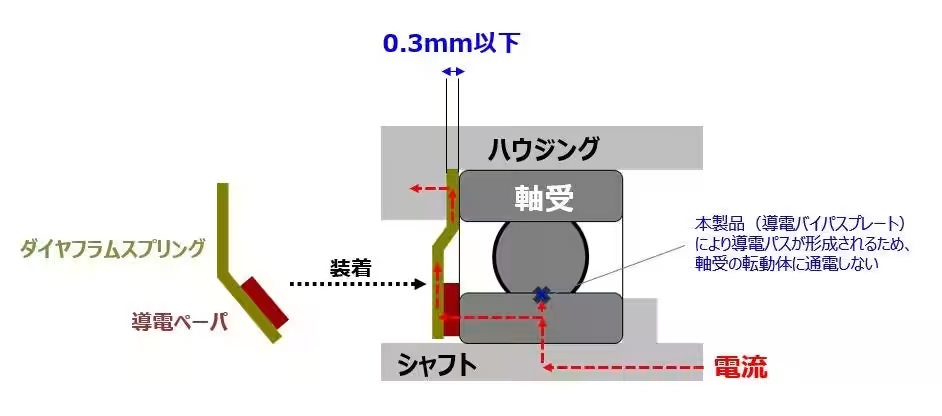

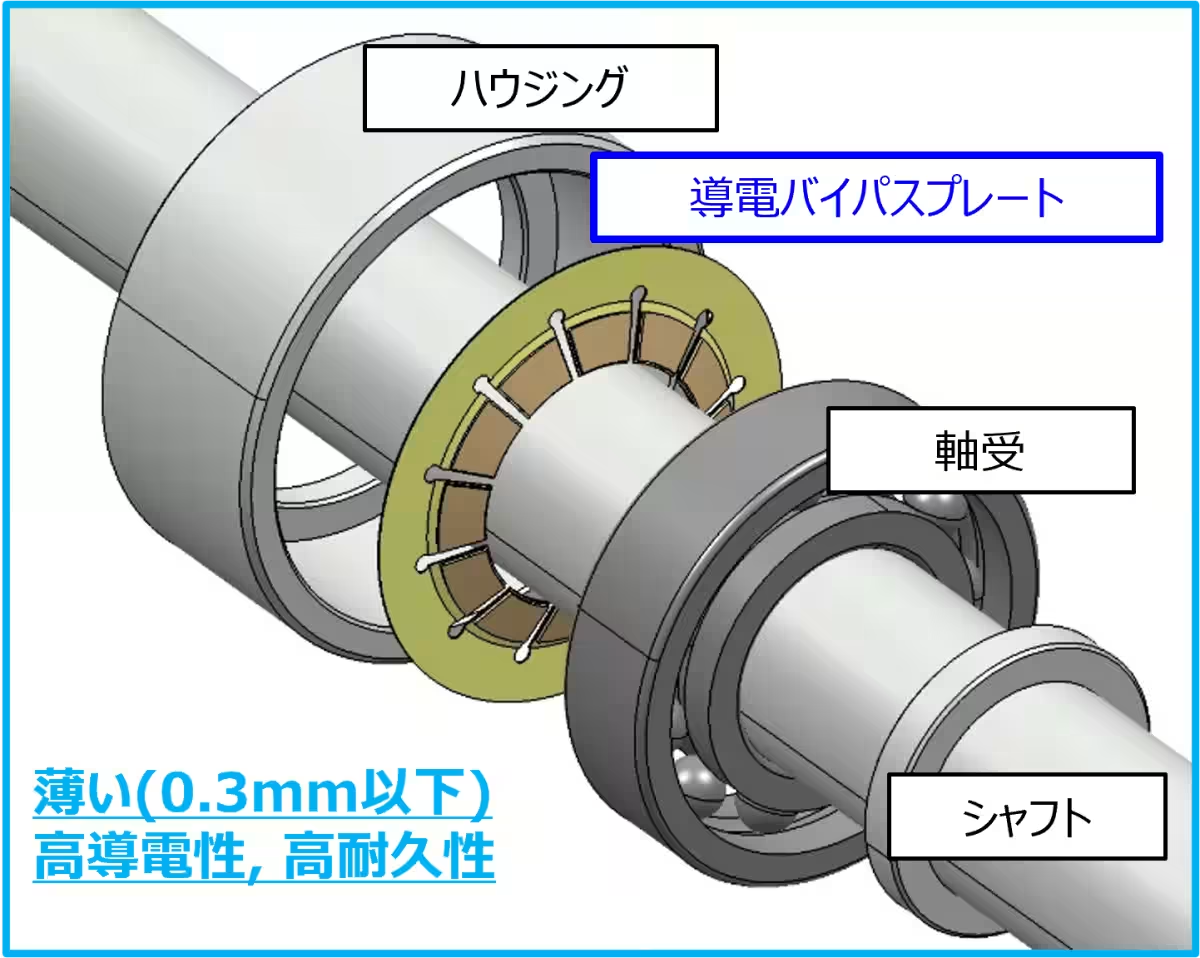

NSK Warner achieved a remarkable balance of high conductivity and space efficiency through its unique conductive paper technology and an innovative product structure that utilizes spring force. Unlike conventional conductive items that require complex bonding processes, the new bypass plate can be easily inserted between the bearing and housing, simplifying installation.

- - High Conductivity: The new conductive item significantly exceeds the performance of existing ring-type conductive solutions, showing more than tenfold conductivity improvement as of October 2025, based on NSK Warner's internal testing.

- - Space Efficiency: With a thickness of just 0.3mm, this product is less than one-tenth the thickness of comparable products, allowing for more efficient space utilization within the electric drive unit.

3. Technological Innovations

The development of this conductive bypass plate hinges on a couple of key innovations:

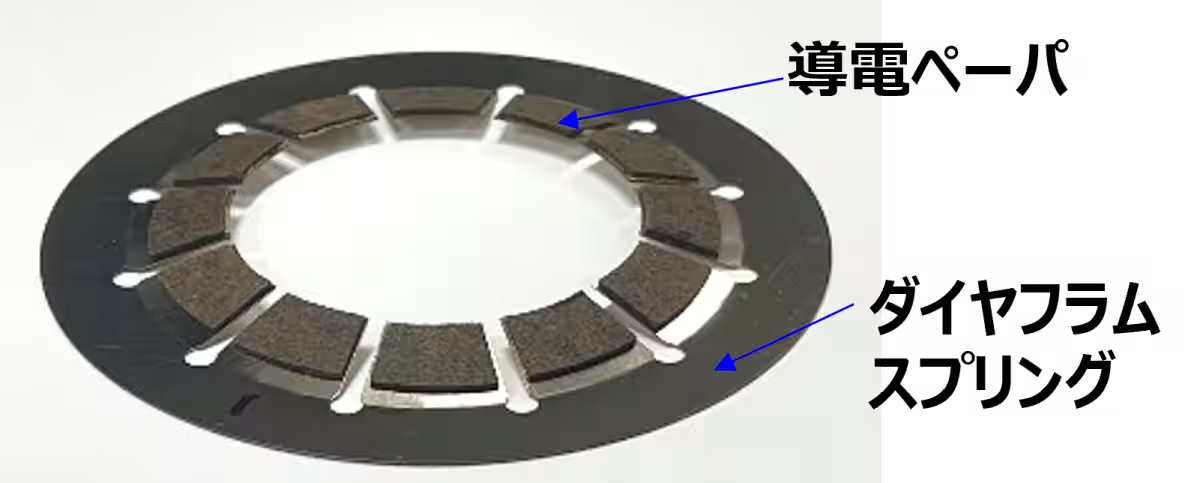

- - Conductive Paper: The recently developed conductive paper greatly enhances conductivity by over six times compared to previous technologies. It also retains a porous structure, allowing oil to flow through, facilitating its use in oil-based conditions.

- - Spring Force Utilization: The structural design incorporates a spring mechanism that maintains stable contact between the conductive paper and the inner ring of the bearing. Unlike other solutions that rely on contact with curves, this method ensures a uniform contact surface, minimizing space requirements and maximizing efficiency.

By integrating these technologies, NSK Warner's new bypass plate effectively mitigates electric corrosion and enhances EMC performance in electric vehicle drive components, all while maintaining design flexibility.

About NSK Warner

Founded in 1964 as a joint venture between NSK Ltd. and BorgWarner Inc., NSK Warner has been a key player in the automotive sector for over fifty years. Leveraging the innovative technologies of its parent companies, NSK Warner specializes in manufacturing clutch products and has built a trusted reputation for delivering reliable automotive solutions globally.

NSK Warner continues to push the envelope in 'Torque Transmission' technology by integrating new innovations to create value for customers. Its mission is to contribute to societal progress through technological advancements, providing products and services that meet emerging needs and striving for a sustainable and prosperous future.

About NSK

Since producing Japan's first bearing in 1916, NSK has remained at the forefront of bearing and automotive component innovation for over a century. With a global presence in about 30 countries, NSK ranks third in the world for bearings and is a leader in ball screws and electric power steering.

Emphasizing a philosophy of contributing to a smooth and safe society, NSK aims to strengthen the bonds between people across nations. Its vision for 2026 includes a commitment to co-create impactful value in response to societal expectations, balancing corporate growth with contributions to society.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.