Tekkens Group Receives Building Technology Performance Certification for MIRACR Method Improvements

Tekkens Group's Cutting-Edge MIRACR Method Receives Certification

Tekkens Group, headquartered in Chiyoda, Tokyo and led by President Taishi Ito, has achieved a significant milestone in construction innovation with the recent adaptation of their proprietary MIRACR method. This construction technology, which utilizes a hybrid RC beam and steel column structure, has undergone substantial testing and improvements. On April 14, 2025, the Japan Architectural Testing Institute awarded the MIRACR method a Building Technology Performance Certification, expanding its application range for various structural components.

Background of the MIRACR Method

The MIRACR method is designed to enhance the construction of logistical warehouses and other buildings by minimizing construction time and costs. This innovative construction technique marries reinforced concrete (RC) columns—with their high axial load-bearing capabilities— to steel beams, allowing for long spans. Previously, the method struggled with integrating variable shapes such as step beams and eccentric beams, and it lacked compatibility with higher-strength materials that are increasingly prevalent in modern construction, making it difficult to apply in the context of high-rise or large-span structures.

Key Updates in Certification

Certification Reference Numbers

- - GBRC Performance Certification No. 06-13 (November 7, 2006)

- - GBRC Performance Certification No. 06-13 Revision 1 (April 14, 2025)

Expanded Application Details

- - Innovative Design Methods Added: Inclusion of step beams and eccentric beams.

- - Expanded Material Applicability: Increased concrete strength up to 60 N/mm², reinforcing steel grade of 490, and steel material grade of 520.

- - Building Applicability Upgraded: Adaptability now extends to structures with heights below 60 meters.

These adjustments are aimed at improving both the versatility and strength of the method to meet diverse building requirements in modern environments.

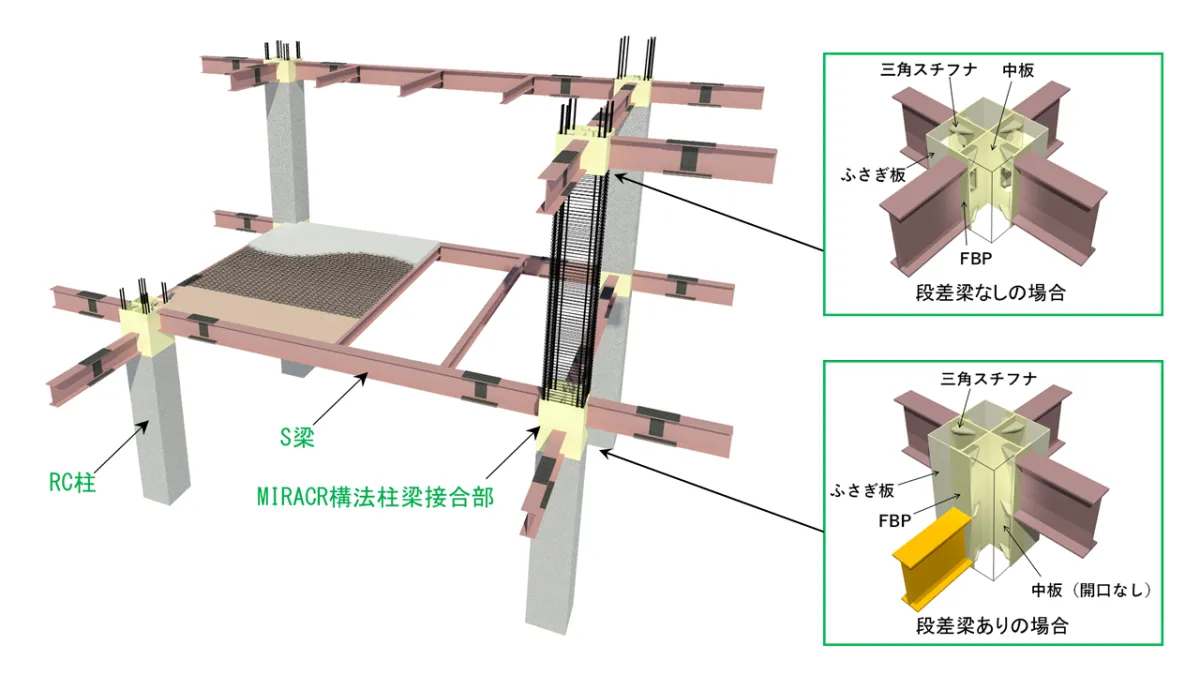

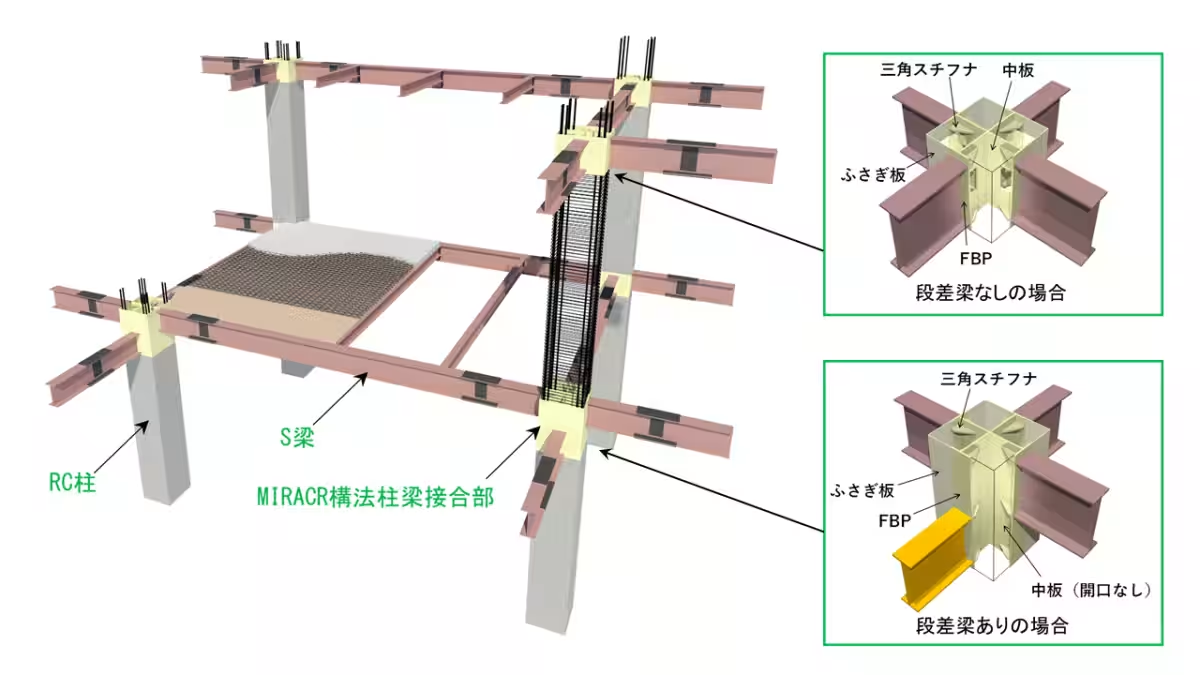

How the MIRACR Method Works

Within the MIRACR design, the connections between the RC columns and steel beams utilize a Face Bearing Plate (FBP) at the beam ends, supported internally by intermediate plates and triangular stiffeners. This configuration allows for effective stress transmission across connections, ensuring robust structural integrity. Additionally, the FBP absorbs deviations within the beams, providing a streamlined approach that prevents interference between the column’s main reinforcement and beam flanges. This innovative design can accommodate various connection forms, establishing the MIRACR method as not just a construction technique, but a comprehensive and adaptable structural solution.

Future Directions

Tekkens Group intends to leverage the possibilities offered by the newly acquired certification to promote economical and rational design methodologies across a variety of structures. These include large-scale logistics facilities, commercial complexes, data centers, and production plants, showcasing the method's adaptability and effectiveness in contemporary architecture.

Contact for Technical Inquiries

For further inquiries about the technology, please contact:

Tekkens Group, Construction Technology Division

Research and Development Center Environmental Group

9-1 Shinizumi, Narita, Chiba 286-0825, Japan

Telephone: 0476-36-2371

With these advancements, the MIRACR method is positioned to meet the demands of the future construction landscape, offering innovative solutions that cater to an increasingly complex building environment.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.