Revealing the True Factors Determining Foam Absorption Limits: A Breakthrough Discovery

Understanding Foam's Absorption Capacity

Foam is widely utilized in everyday products such as detergents, food, cosmetics, and even firefighting materials. Until recently, the absorption capacity of foam—or its ability to retain liquid—was predominantly believed to be determined by osmotic pressure. However, observations indicated that actual foam can expel water at significantly smaller heights than expected, prompting the need to explore this phenomenon further.

A team of researchers, including Aoi Kaneda (then a graduate student) and Professor Rei Kurita from the Graduate School of Science at Tokyo Metropolitan University, conducted an in-depth study to measure foam's absorption limits. They discovered that a remarkably low effective osmotic pressure, about 1/30th of the theoretical value, governs these limits. This finding reveals that the dynamics of liquid flow and internal bubble movement within the foam are intimately connected, which influences the foam's mechanical response and its absorption capacity.

Key Findings

1. The absorption limits of foam are dictated not by traditional osmotic pressure, but by mechanical properties such as yield stress.

2. The effective osmotic pressure was found to peak at approximately 70 Pa, significantly lower than the theoretical osmotic pressure of 2000 Pa.

3. The absorption limits directly correlate with the ratio of surface tension to bubble size and are independent of the type of surfactant used or how easily it collapses.

4. This mechanical response is a common trait observed in other soft jamming systems, like blood flow and emulsions, hinting at broad implications for fundamental and applied research.

Background of the Study

Foam consists of numerous bubbles densely packed in liquid, providing unique properties such as absorbency and thermal insulation. The ability of foam to hold liquid—its absorption limit—is a crucial metric in sectors like cleaning and environmental technology. Historically, it was understood that the internal bubble structure and collision due to compression lead to an increase in surface area, which reduces surface energy and generates osmotic pressure. Theoretically, it was presumed that liquid would only be lost when the pressure surpassed this osmotic level.

However, in practice, this theoretical osmotic pressure could only hold true for heights exceeding one meter, while foam would often expel liquid past a few centimeters, thus raising questions about the discrepancies between theory and reality.

Research Insights

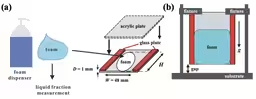

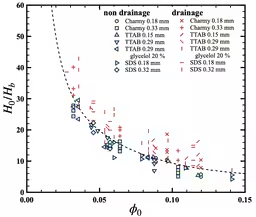

The research group created foam from commercial surfactant solutions using foam pumps, placing it between two acrylic plates to observe drainage. They found that the height of the foam and the gravity of the liquid inside dictated whether drainage would occur. By experimenting with various surfactants such as TTAB and SDS, they varied average bubble size, liquid fraction, and viscosity to observe drainage outcomes. Their findings indicate that drainage conditions are governed universally by a relationship between these parameters.

From the balance of gravity and osmotic pressure, the effective osmotic pressure can be derived using density. The maximum value, around 70 Pa, starkly contrasts with the theoretical pressure of 2000 Pa, underscoring the need for a revised understanding of foam mechanics.

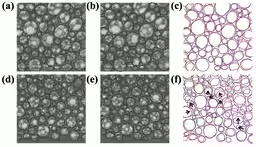

Furthermore, the study noted that when liquid is expelled from foam, the internal bubble structure behaves dynamically. Specifically, during drainage, bubbles reorganized themselves, aligning with the observed yield stress, confirming that this stress marks the threshold beyond which fluid is expelled. These insights yield a new comprehension of the physical mechanics at play, linking bubble rearrangement to liquid expulsion, driven by yield stress.

Implications of the Research

This discovery opens doors to a rapid assessment of foam absorption capabilities, suggesting an innovative method for evaluating foam products. The relationship between mechanical response and fluid absorption could serve as a simplified measurement standard, providing insights into surfactant selection and formulation design in product development.

The importance of this study transcends just foam physics; the underlying principles have universal applicability to various soft matter systems, including blood and biological tissues, thereby inviting further exploration into their flow dynamics and absorption behavior.

In conclusion, these findings challenge the static models previously applied to foam mechanics, advocating for a dynamic, non-equilibrium framework. As this research progresses, it holds the potential to significantly influence both theoretical studies and practical applications across diverse industries, from cleaning agents to biomedical materials.

Visuals

- - Figure 1: Schematic of the experimental apparatus observing drainage.

- - Figure 2: Conditions showing the draining or non-draining state across various experimental setups.

- - Figure 3: Internal structural changes of foam under draining and non-draining conditions, illustrating the kinetic behavior of bubbles.

Research Significance

The findings bolster rapid evaluation methodologies in foam absorption, crucial in guiding product design, and emphasize the need to rethink traditional foam dynamics from a more action-oriented perspective.

The implications extend further, potentially impacting the study of fluid dynamics in biological contexts, paving the way for advancements across a spectrum of scientific and industrial fields.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.