PI Unveils Groundbreaking Miniaturized Alignment Engine for High-Volume E/O Wafer-Level Testing

PI's Innovative Miniaturized Alignment Engine

Introduction

In a significant advancement for the photonics industry, PI (Physik Instrumente) has launched a new technology platform that revolutionizes the way electro-optical devices are tested at the wafer level. This cutting-edge platform is specifically designed to conduct simultaneous validations of electrical and optical functionalities, addressing the growing needs of high-volume production.

Enhanced Efficiency with Parallel Testing

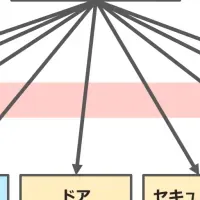

One of the standout features of this new platform is its ability to operate multiple miniaturized alignment engines in parallel. This capability allows for simultaneous electro-optical probing at various test sites, dramatically improving throughput and reducing the overall cost of testing. The systematic shift from sequential, laboratory-style alignment testing to high-volume, repeatable wafer-level testing represents a pivotal transformation for EPIC (Electronics, Photonics, and Integrated Circuits) manufacturers.

The compact architecture of the platform is also noteworthy; it is built to be compatible with Automatic Test Equipment (ATE), making it easier to integrate into existing production lines. This integration supports the trend towards automation in high-tech manufacturing systems, ensuring that manufacturers can scale operations without the need for extensive reconfiguration.

The Introduction of FAU Ranging

A key innovation featured in PI's new alignment engine is the FAU (Fiber-to-Wafer) ranging technology. Utilizing interferometry-based fly-height measurement, FAU ranging smartly leverages existing fiber channels, avoiding additional hardware and saving valuable space in the testing setup. This technology measures the distance between the fiber and the wafer at critical points, enabling stable probing and consistent optical coupling throughout the testing process.

Dr. Markus Simon from PI highlighted this advancement, stating, "With FAU ranging, we pave the way for trench-based photonic edge coupling, saving wafer real estate, lowering device costs, and enhancing design flexibility for EPIC manufacturers." This statement underscores the impact of the new technology not just on testing efficiency, but also on future design possibilities in photonics.

Implications for the Industry

The implications of PI's miniaturized alignment engine extend far beyond mere operational efficiency. As the demand for faster and more accurate testing methods increases within the photonics sector, the introduction of this platform offers manufacturers a streamlined solution that aligns with the industry's evolving dynamics. The combination of high-density electrical probing and automated photonic alignment will empower manufacturers to keep pace with the rapid innovations in electro-optical technology.

Furthermore, by facilitating trench-based photonic edge coupling, this technology could result in thinner devices, reduced waste, and greater energy efficiency—factors that are becoming increasingly critical in today’s market.

Conclusion

PI's new miniaturized alignment engine platform represents a leap forward in electro-optical wafer-level testing, aligning with the rigorous demands of high-volume manufacturing. As the technology continues to evolve, it is clear that such innovations will play a vital role in shaping the future of the photonics industry. PI is set to showcase this groundbreaking platform at the upcoming SPIE Photonics West event in 2026, highlighting their commitment to advancing precision testing solutions.

In conclusion, the transition to this new platform not only signals a shift in testing methodologies but also sets a new standard for efficiency and innovation within the photonics sector, ultimately driving higher performance and lower costs in modern electro-optical device manufacturing.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.