AI Utilization and the Risk of Dependency in Manufacturing: Key Insights from CADDi’s Survey

Exploring the Risk of Dependency and AI Utilization in Manufacturing

In a recent survey conducted by CADDi Corporation, a startup headquartered in Taito, Tokyo, it was revealed that a staggering 98% of workers in the manufacturing sector have encountered losses attributable to dependency on specific individuals for certain tasks or decisions. This survey included responses from 120 manufacturing firms and 163 employees, aiming to delve into the critical issue of dependency risks and the promising role AI can play in addressing these concerns.

Key Findings

The survey shed light on the persistent challenges faced by the manufacturing industry, particularly the issues of labor shortages and the complexities of skill transfer. One of the primary inquiries was centered on the risks associated with reliance on individuals who possess specific knowledge, especially in the context of significant HR changes occurring every autumn.

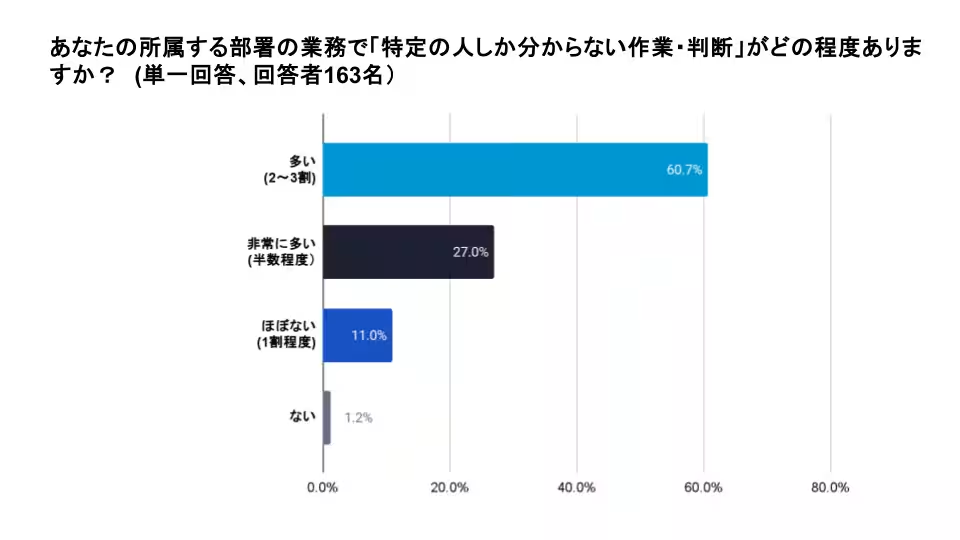

Among the notable findings, 98.7% of respondents acknowledged the existence of tasks or decisions that only certain individuals could handle. Specifically, about 60% indicated that approximately 20-30% of their work was susceptible to dependency, while nearly 30% reported that this dependency represented around half of their tasks. This alarming trend underscores the depth of the issue.

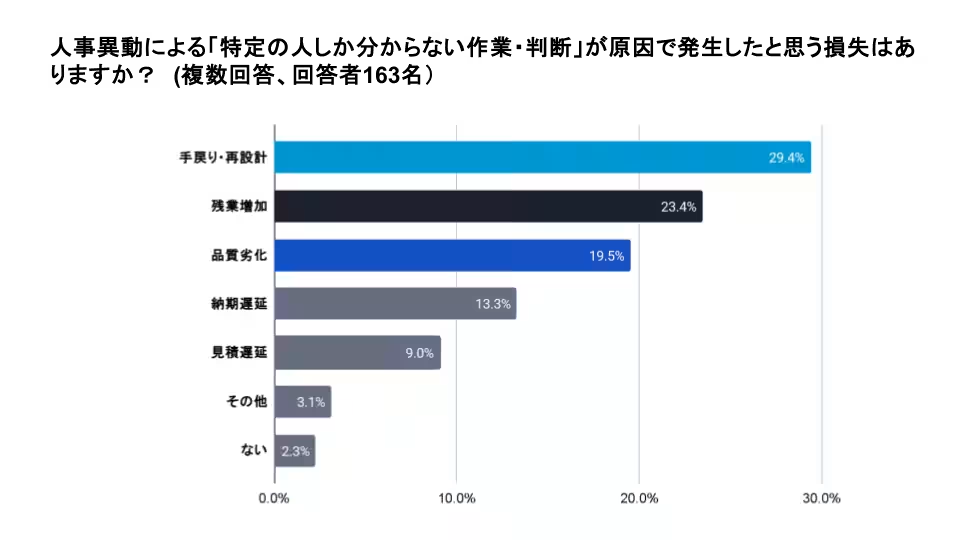

When it comes to the impact of dependency arising from HR changes, more than 29% of respondents cited ‘rework and redesign’ as a major consequence, followed closely by an increase in overtime (23.4%). Evidently, the effects of dependency extend far beyond operational inefficiency, crystallizing into heightened costs and diminished productivity.

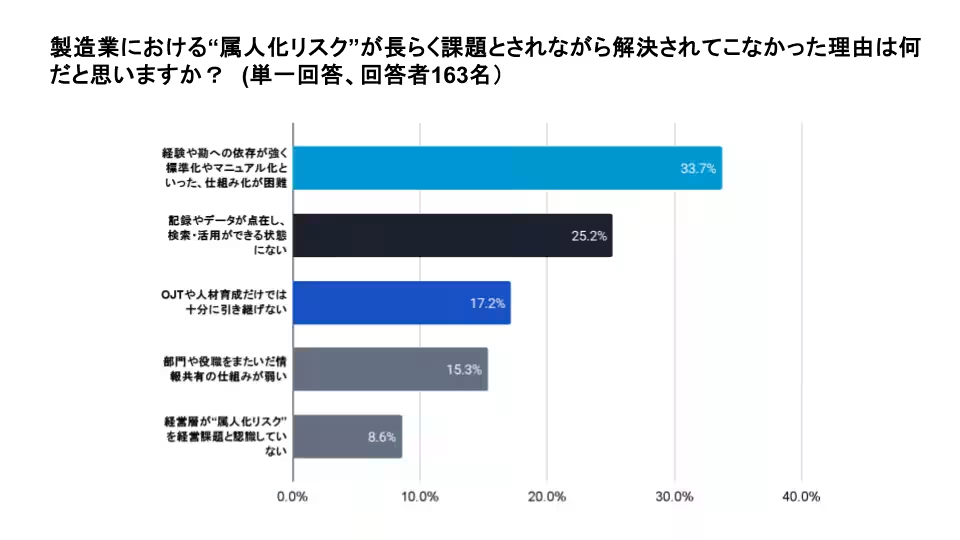

Moreover, the survey uncovered underlying reasons for the stagnation in addressing dependency risks. A significant 33.7% highlighted a strong reliance on ‘experience and intuition’, which complicates standardization efforts. Additionally, 25.2% reported issues related to fragmented data and its ineffective utilization, indicating existing challenges both in systems and organizational culture.

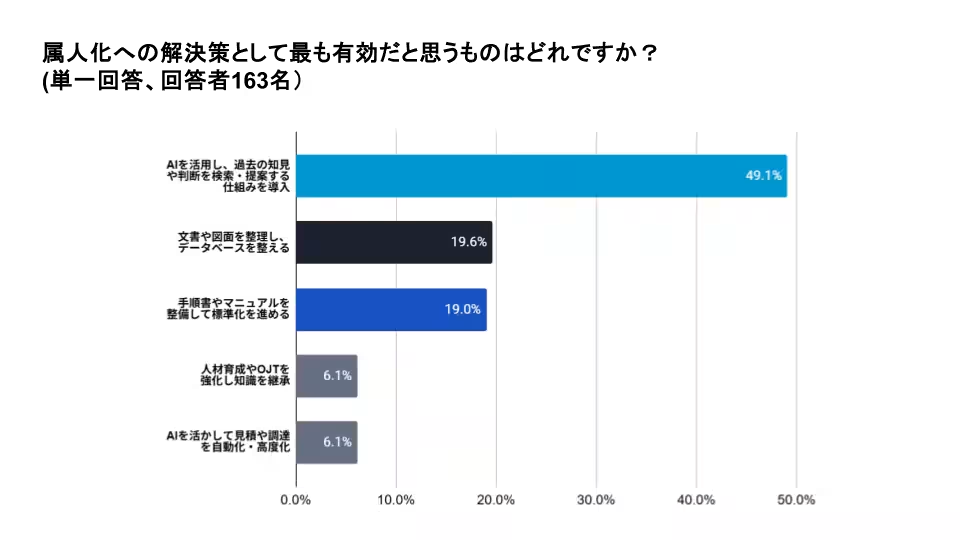

In terms of potential solutions, approximately half of those surveyed (49.1%) identified AI-driven insights and proposals for knowledge retrieval as the most effective remedy for mitigating dependency risks. This growing interest in AI not only signifies a shift in perspective but also offers a tangible path toward enhancing productivity and preserving critical knowledge within organizations.

Conclusion

Through this survey, it becomes increasingly apparent that dependency remains a substantial roadblock within the manufacturing sector, directly impacting productivity and operational costs. The reality that 20-30% or even up to 50% of tasks are reliant on specific individuals is alarming, suggesting a pressing need for strategic intervention.

The presence of structural and cultural barriers such as reliance on ‘experience and intuition’ and data fragmentation presents formidable challenges that traditional methods of training and manual development may no longer suffice to overcome.

Amidst these challenges, the significant acknowledgment of AI's potential role in facilitating knowledge transfer and decision-making highlights a shift toward innovative, technology-driven solutions. As the industry grapples with labor shortages and generational transitions, the imperative to address dependency as a tangible management risk has never been more critical. The findings indicate a need for organizations to adapt and redefine dependency from an ‘unavoidable challenge’ to a ‘strategic risk that must be managed’, advocating for the prudent adoption of digital technologies, including AI, as a cornerstone of organizational strategy.

As CADDi continues to leverage its platform in creating new value from scattered data and experience, the company exemplifies how the manufacturing sector can transform these challenges into opportunities for modernization and improvement, enhancing competitiveness in a rapidly evolving landscape.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.