NEC Nexsolution's Obbligato Enhances Itou's Competitive Edge Through DX

Driving Manufacturing DX: NEC Nexsolutions and Itou Chotmwave

In the rapidly evolving landscape of medical devices, NEC Nexsolutions has stepped up to facilitate a transformative shift for Itou Chotmwave, a medical device manufacturer based in Kawaguchi City, Saitama. By adopting NEC's Obbligato PLM solution, Itou aims to drastically improve its productivity by reducing indirect operations that had long hindered the development process.

The Shift from Analog to Digital

Traditionally, Itou Chotmwave relied on analog media for sharing design documents and parts lists throughout its development processes. This longstanding practice resulted in cumbersome indirect operations and an increase in development time. As a manufacturer of high-quality ultrasound and electrical stimulation devices, Itou recognized that the efficiency of their workflows was directly linked to their competitive edge in the market.

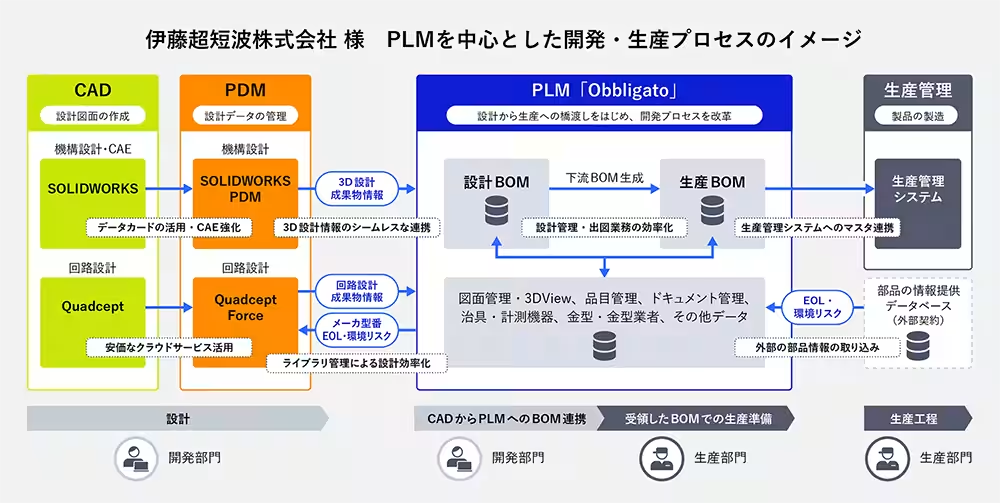

To address these challenges, Itou Chotmwave turned to NEC Nexsolutions' expertise, implementing a comprehensive system that integrates mechanical and electrical CAD tools, Product Lifecycle Management (PLM), and production management systems. Notably, the collaboration between Obbligato, SOLIDWORKS, and Quadcept represents a pioneering effort—marking Itou Chotmwave as the first to develop this integrated system.

Understanding PLM: A Game-Changer in Product Management

PLM, or Product Lifecycle Management, serves as a robust information foundation that manages all technical data from a product's inception through its development, manufacturing, sales, and even discontinuation. NEC's Obbligato stands as the top choice in the Japanese market, focusing on seamless management and sharing of crucial product data such as BOM (Bill of Materials) and BOP (Bill of Process).

According to Techno System Research, Obbligato dominated the market with a substantial share in 2024, making it a strategic choice for companies focused on improving operational efficiency.

Outcomes of the Implementation

The integration of Obbligato with SOLIDWORKS and Quadcept has allowed Itou Chotmwave to promote its DX (Digital Transformation) by reducing the reliance on analog systems significantly. Here are some key outcomes:

- - Streamlined Information Exchange: The digitalization of design documents eliminated the need for printing and physical document management, saving time and resources.

- - Efficiency in Design Tasks: Unifying operational rules across CAD systems improved the searchability of designs and parts information.

- - Swift Approval Processes: The digital review capabilities enabled faster approvals, regardless of location, enhancing overall productivity.

- - Enhanced Quality Control: By digitalizing and sharing component information, the company could focus more on quality checks and risk management effectively.

- - Real-time Management of Development History: Structured workflows provided progress tracking and made approval tasks more efficient, with added oversight for design changes.

With this collaborative effort, NEC Nexsolutions and Itou Chotmwave are setting a remarkable precedent for manufacturing entities, illustrating how the right tools can drive substantial reforms and empower ongoing growth.

Looking Towards the Future

As NEC Nexsolutions continues to support Itou Chotmwave's pursuit of sustainable growth, its commitment to help clients soar in their digital transformation journeys remains unyielding. The collaboration underscores the potential for adopting advanced solutions to nurture competitiveness in an age where digital integration is key.

For more detailed insights into this case study, download the comprehensive leaflet here or explore further on NEC Nexsolutions' page.

To know more about Quadcept and their offerings, visit their service site. Discover how Itou Chotmwave has revolutionized their operations with the integration of PLM solutions like Obbligato by checking this case study.

In the competitive landscape of healthcare technology, NEC Nexsolutions' robust solutions, paired with forward-thinking clients like Itou Chotmwave, are poised to set new standards for operational excellence in manufacturing.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.