Sumitomo Bakelite Develops Wear-Resistant Phenolic Resin for Brake Pads

Introduction

Sumitomo Bakelite Co., Ltd., based in Shinagawa, Tokyo, has made significant strides in automotive technology with the development of a new binder resin specifically designed for brake pads. Named Sumilight Resin® PR-56531, this wear-resistant amide-modified phenolic resin promises to address one of the automotive industry's pressing concerns: brake dust emissions. As European emission regulations tighten, particularly the Euro 7 standards set to be enforced from 2028, the need for innovative solutions to reduce brake dust has become critical.

Background of Development

The push for reduced air pollution has led to stricter regulations on harmful emissions from vehicles. The Euro 7 regulations will include specific limits on particulate matter released during braking, which underscores the urgency for the development of more efficient brake systems. Recognizing this need, Sumitomo Bakelite has developed PR-56531 as a binder resin that contributes to minimizing wear particulate emissions from brake pads.

Features of Sumilight Resin® PR-56531

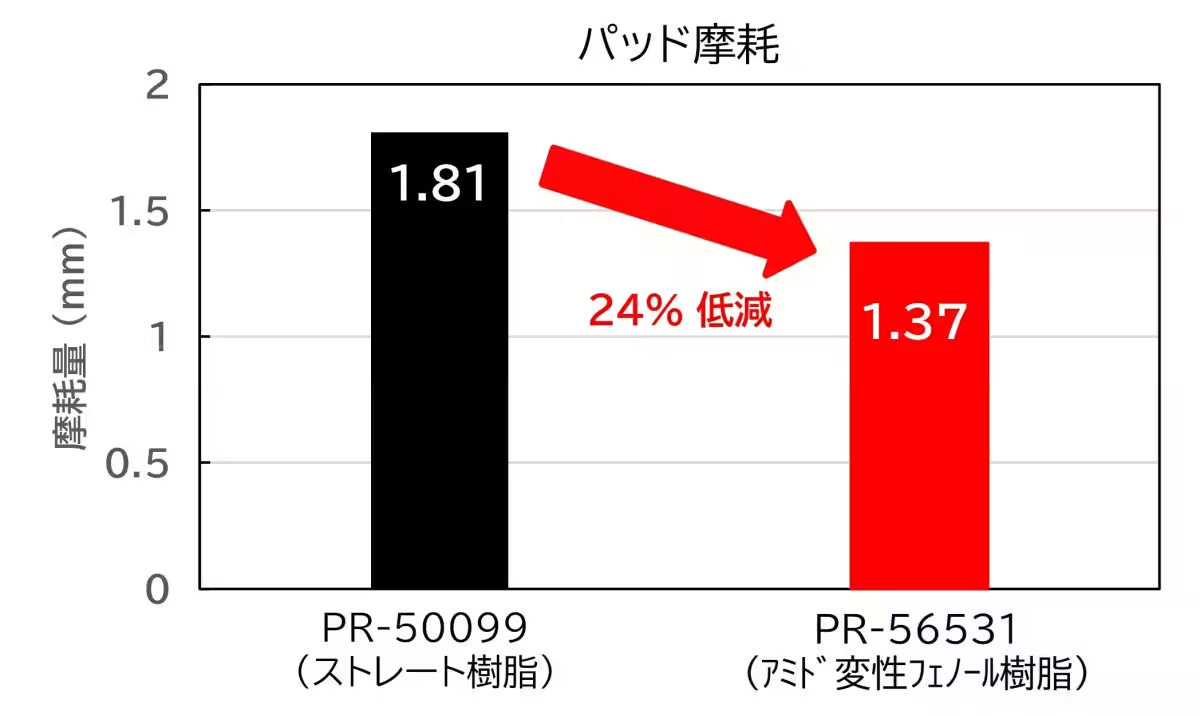

The newly developed resin exhibits excellent wear resistance, enhancing the durability of brake pads. Internal dynamometer tests have demonstrated a 24% reduction in wear compared to traditional unmodified phenolic resins. This resin not only maintains friction performance but also allows for the integration into existing manufacturing processes, making it suitable for various friction material manufacturing methods. Furthermore, Sumitomo Bakelite’s global production capabilities enable local supply from plants across China, Southeast Asia, and Europe, ensuring quick response times to customer demands.

Figure: Wear Resistance Data for Brake Pad Model Compounds

Testing Conditions: Initial braking speed 100 km/h, braking deceleration 3.5 m/s², pre-brake temperature 300°C, 300 braking cycles. Data derived from internal evaluations conducted with a 1/10 scale dynamometer.

Future Plans

With the growing significance of environmental concerns, Sumitomo Bakelite aims to expand its market share as a high-performance binder resin in Europe. The company is actively working towards entering the market for brake friction materials compliant with Euro 7 regulations and is conducting performance evaluations in collaboration with friction material manufacturers both domestically and internationally. Goals include beginning mass production and sales by 2027, targeting annual revenue of 1 billion yen globally.

Sumitomo Bakelite is committed not only to Euro 7 compliance but also to broader sustainability initiatives, including the electrification of automobiles and the development of high-performance braking systems. The company plans to enhance its product lineup to meet next-generation demands, focusing on rapid molding technologies and the integration of biomass materials.

Contact Information

For inquiries regarding this matter, please reach out to:

Sumitomo Bakelite Co., Ltd.

Materials Solutions Sales Division, Polymer Sales Department

Phone: 03-5462-4241

Contact Us Here

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.