Glico Manufacturing Japan Adopts MISUMI floow for Enhanced Efficiency

Glico Manufacturing Japan Enhances Operations with MISUMI floow

Glico Manufacturing Japan, a key player in the Glico Group responsible for producing confectioneries, frozen desserts, processed foods, and dairy products, has recently adopted the indirect materials total cost reduction service, MISUMI floow. This move marks the first implementation of the service in their Osaka factory, with plans to expand its application to other facilities including those in Chiba, Mie, and Hyogo.

What is MISUMI floow?

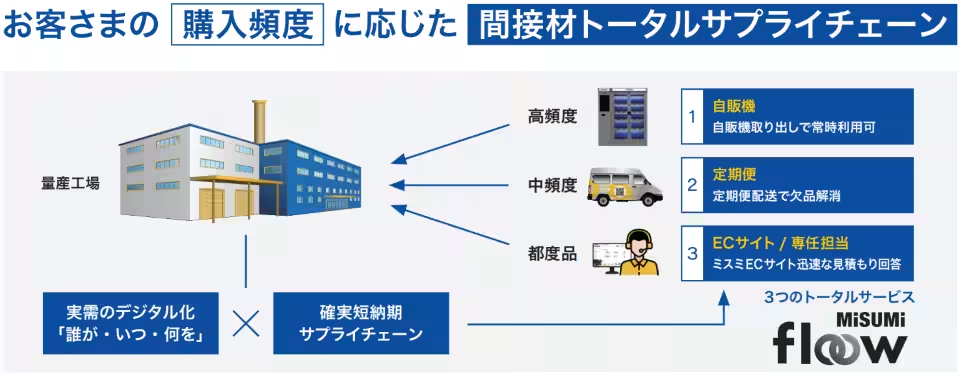

MISUMI floow is a cutting-edge service powered by digital technology that enables streamlined procurement processes based on customer demand data. It facilitates the provision of products through optimal channels, such as vending machines, and significantly reduces the complexities associated with indirect material procurement at manufacturing sites. As businesses look to elevate efficiency, the introduction of this service aims to alleviate operational burdens while enhancing productivity across the board.

The Operational Landscape at Glico Manufacturing Japan

Operating out of one of its 13 factories, the Osaka facility faced challenges with managing various indirect materials across different production lines. Complications arose due to the intricate ordering processes and excess inventory, primarily stemming from a two-tier ordering system managed by the general affairs department. This structure not only increased operational workloads but also strained storage capabilities.

To tackle these issues, Glico decided to implement MISUMI floow. The adoption of vending machines for product distribution, along with automated replenishment directly from MISUMI, has substantially minimized the time spent on ordering and restocking. Additionally, to address food safety concerns, the risk of foreign object contamination has been significantly mitigated through the use of facial recognition technology during product retrieval.

Anticipated Outcomes

Following the integration of MISUMI floow, Glico anticipates a reduction in order processing time by nearly 20%, equating to approximately 107 hours saved annually. The efficiency improvements will also foster a broader digital transformation (DX) strategy throughout the Glico Group, with ongoing projects pushing toward a more integrated operational framework.

Key Benefits Experienced:

1. Enhanced Availability at All Times: With 24/7 access to indirect materials via on-site vending machines, operators can now retrieve the needed supplies precisely when required, improving convenience on the manufacturing floor.

2. Hygiene Management via Contactless Operations: Implementing facial recognition for vending machine access eliminates the need for physical cards, enhancing hygiene protocols and minimizing the risk of foreign substances entering the production environment.

3. Efficiency in Order Processing: Prior to the system overhaul, the general affairs department needed to perform approximately 320 orders annually, taking roughly 20 minutes each. With MISUMI floow, these operations are expected to decrease by 18.8%, allowing for optimized storage and procurement aligned with actual usage.

4. Cost Reductions Through Material Consolidation: Collaborative efforts between Glico and MISUMI to consolidate indirect materials are projected to generate an annual savings of approximately ¥2.27 million by eliminating duplicate inventories across manufacturing lines.

Positive Reception from Leadership

Following the deployment of MISUMI floow, key personnel within Glico Manufacturing Japan have lauded its effectiveness. Keiji Miyazaki, former factory manager of the Osaka site, expressed satisfaction with the dual achievement of reduced inventory levels and enhanced operational efficiency through the vending machine system.

Takashi Hirano, a section chief in the production technology department, mentioned the commitment to broadening the range of items available via vending machines to further enhance operational efficiency. He highlighted that the initiatives at the Osaka facility have been well-received internally, attracting attention from visiting executives and delegations.

Miki Suginami, a section chief in human resources, articulated the company's strategic aim to reduce non-core activities, empowering employees to engage in more productive and fulfilling tasks.

Conclusion

As the Glico Group forges ahead with its digital transformation agenda, the successful implementation of MISUMI floow at Glico Manufacturing Japan stands as a benchmark case. This development not only emphasizes the importance of adapting to technological advancements but also illustrates a growing commitment to enhancing operational efficiency within the manufacturing landscape. With a focus on continual improvement, Glico aims to establish a foundation for sustainable growth and innovation in the years to come.

For detailed insights on the service, you can visit MISUMI floow Service Information and check out customer testimonials that highlight their transformative experiences.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.