Industry Outlook 2026: Key Insights from Manufacturing Sector Executives

Industry Outlook 2026: Insights from Executives in Manufacturing

In a recent survey conducted by CADDi Inc., a Tokyo-based startup dedicated to the digital transformation of the manufacturing sector, insights were gathered from 645 managerial personnel working in various manufacturing fields. The key aim of this survey was to understand the industry's challenges and expectations as we approach 2026.

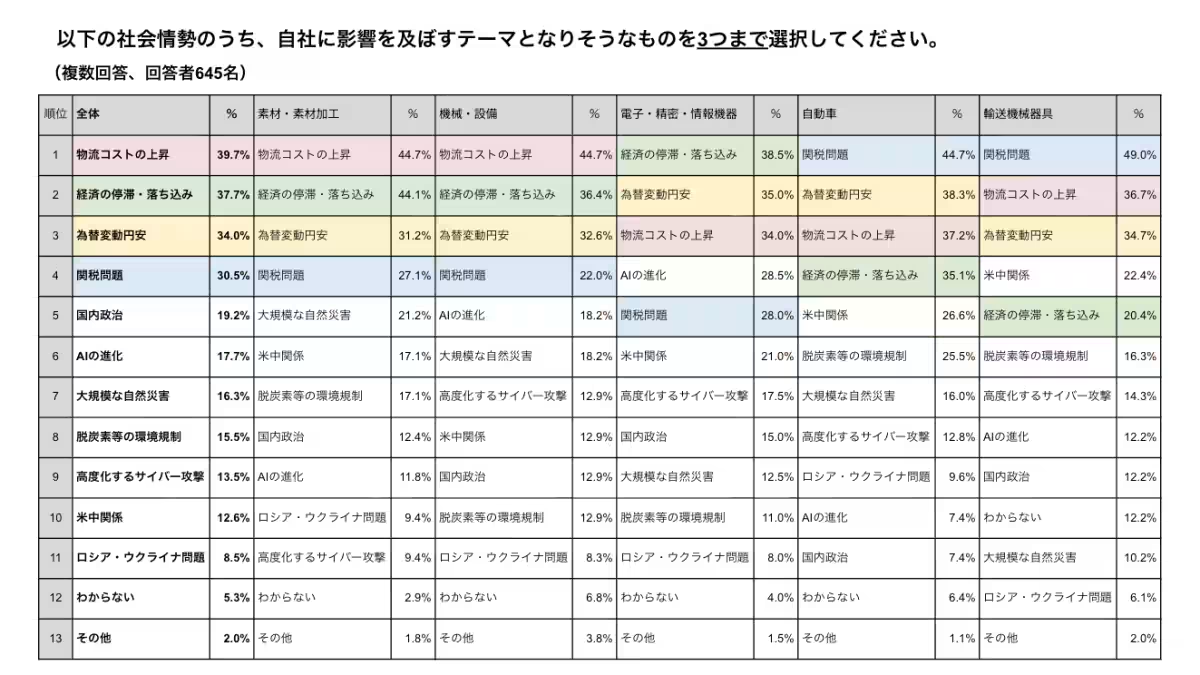

Main Challenges Facing the Manufacturing Industry

According to the findings, several societal and economic factors are impacting the manufacturing sector significantly. The top concern among surveyed executives is the rising logistics costs (39.7%), followed closely by economic stagnation (37.7%) and the devaluation of the yen (34.0%). In the automotive and transportation machinery industries, tariff issues emerged as a primary concern. These issues highlight the unique challenges faced by different sectors within the manufacturing realm.

Economic Impacts

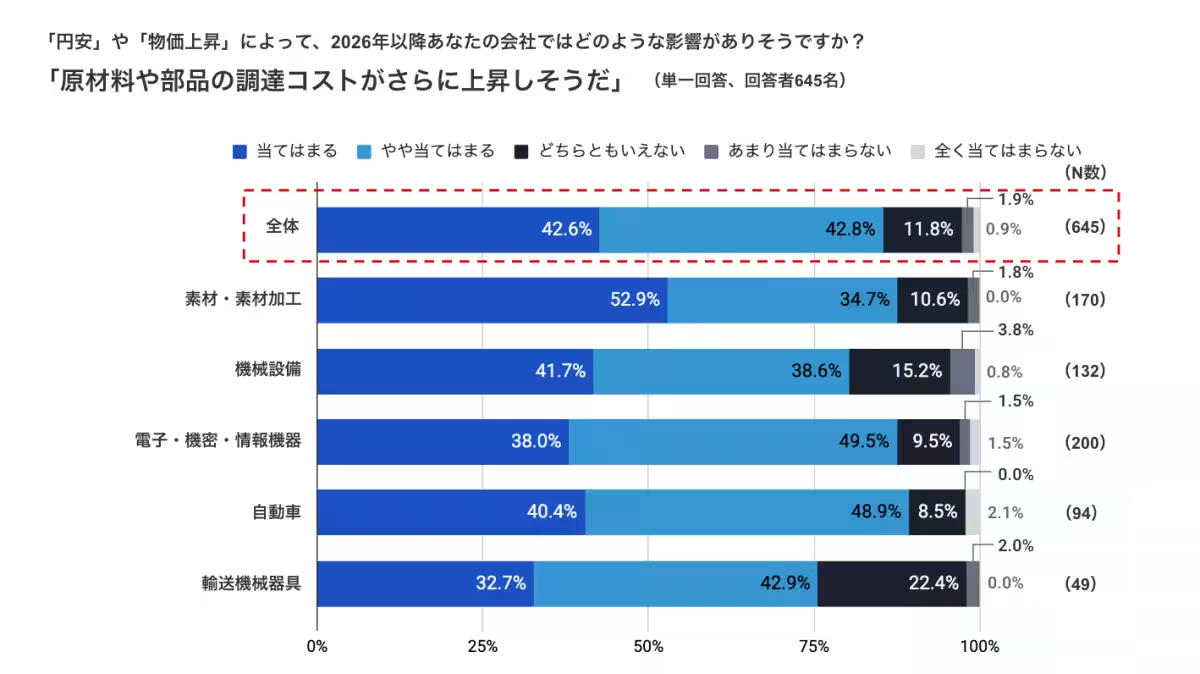

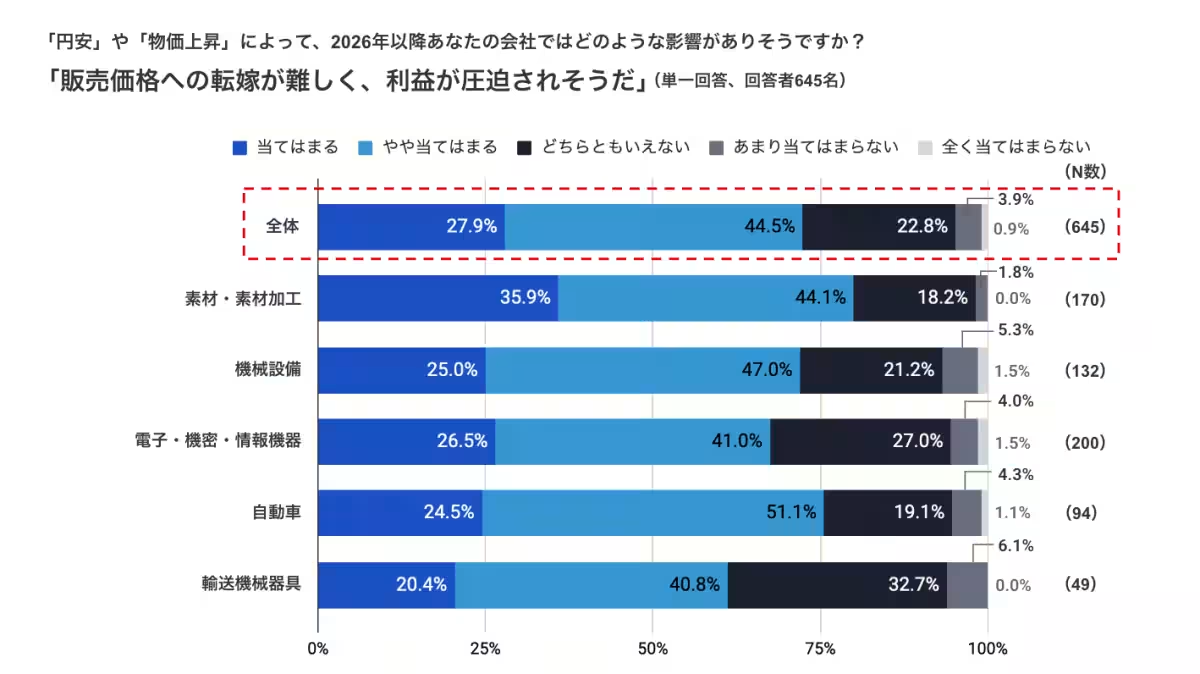

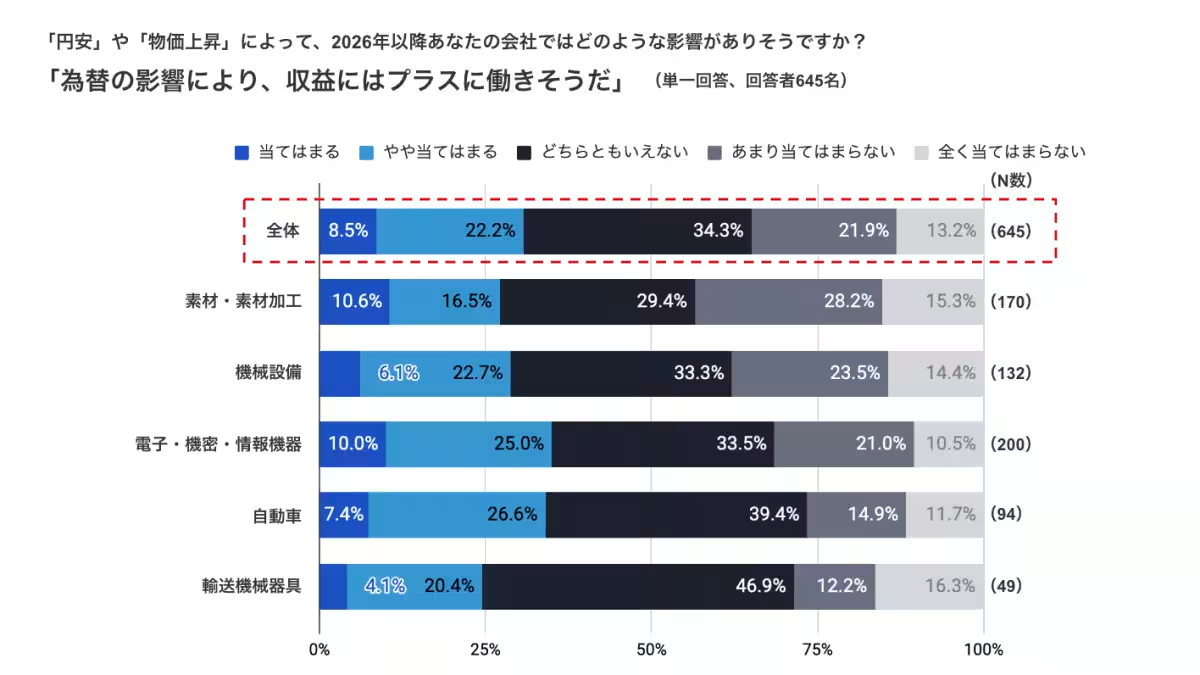

Respondents also reported feeling the pressure from the yen depreciation and rising prices, which have resulted in increasing procurement costs (85.4%). A worrying 72.4% of executives indicated that they cannot pass these costs to customers, consequently leading to squeezed profits. This sentiment suggests that rising prices and currency fluctuations are perceived as detrimental to overall profitability across the sector.

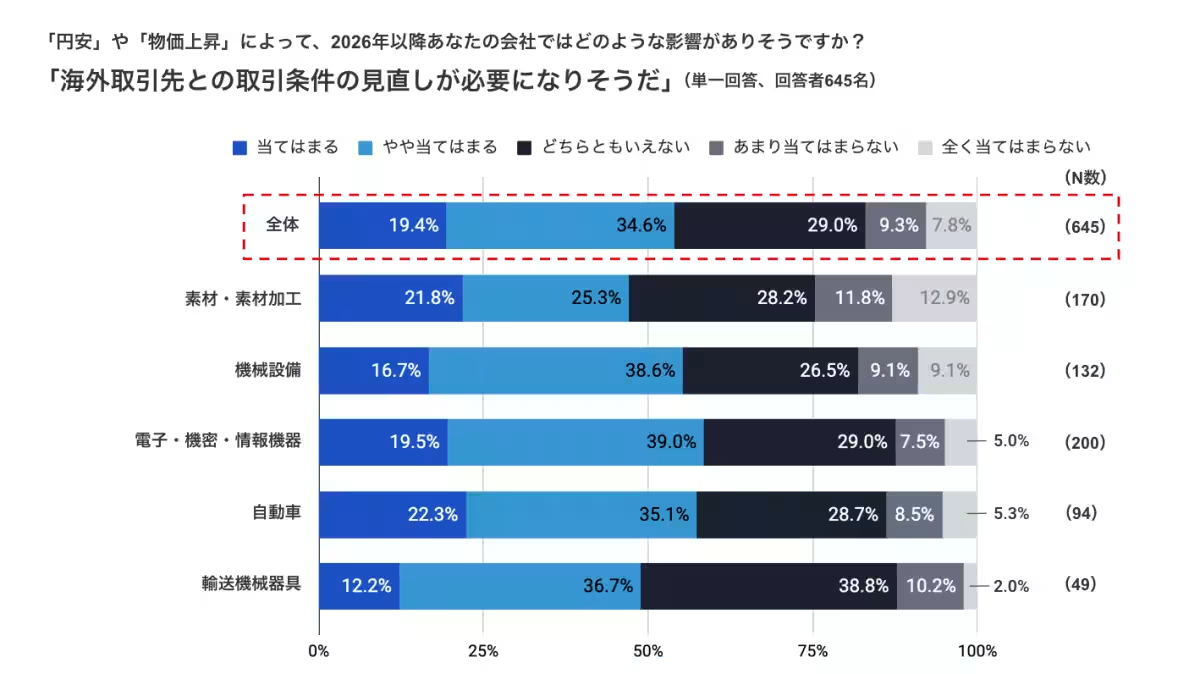

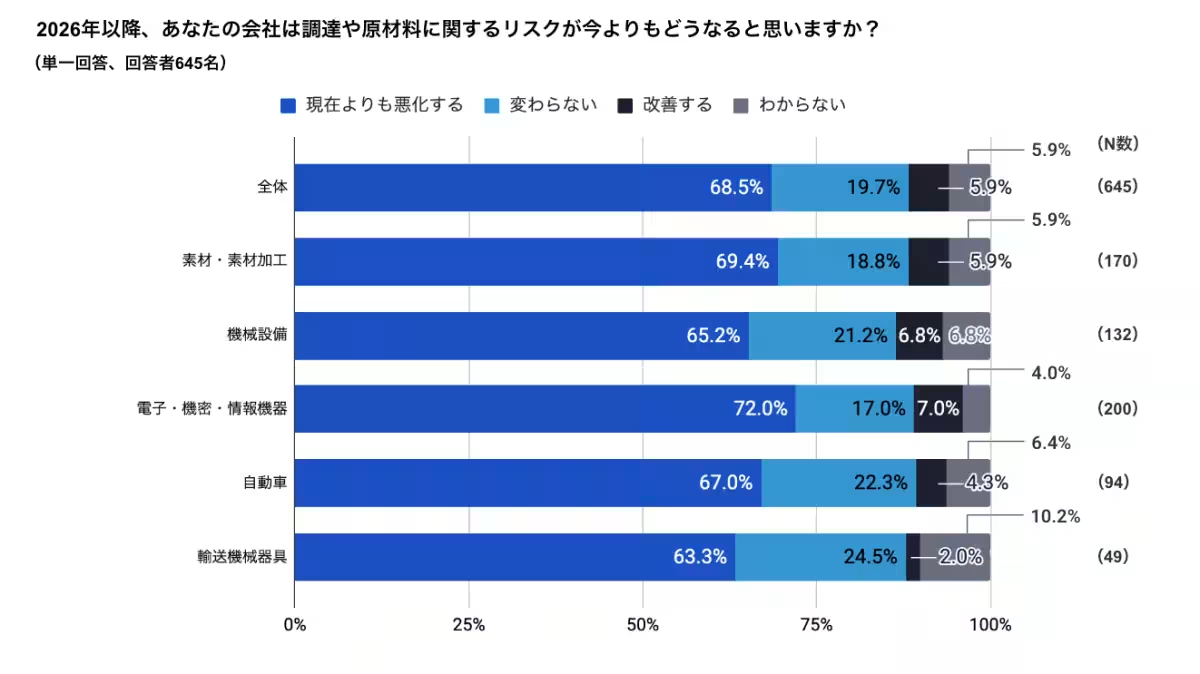

The anticipation of worsening procurement and raw material risks was echoed by 68.5% of respondents, revealing a significant degree of apprehension regarding supply chain stability in the coming years. Many industry leaders acknowledge the urgent need for strategies to mitigate these risks.

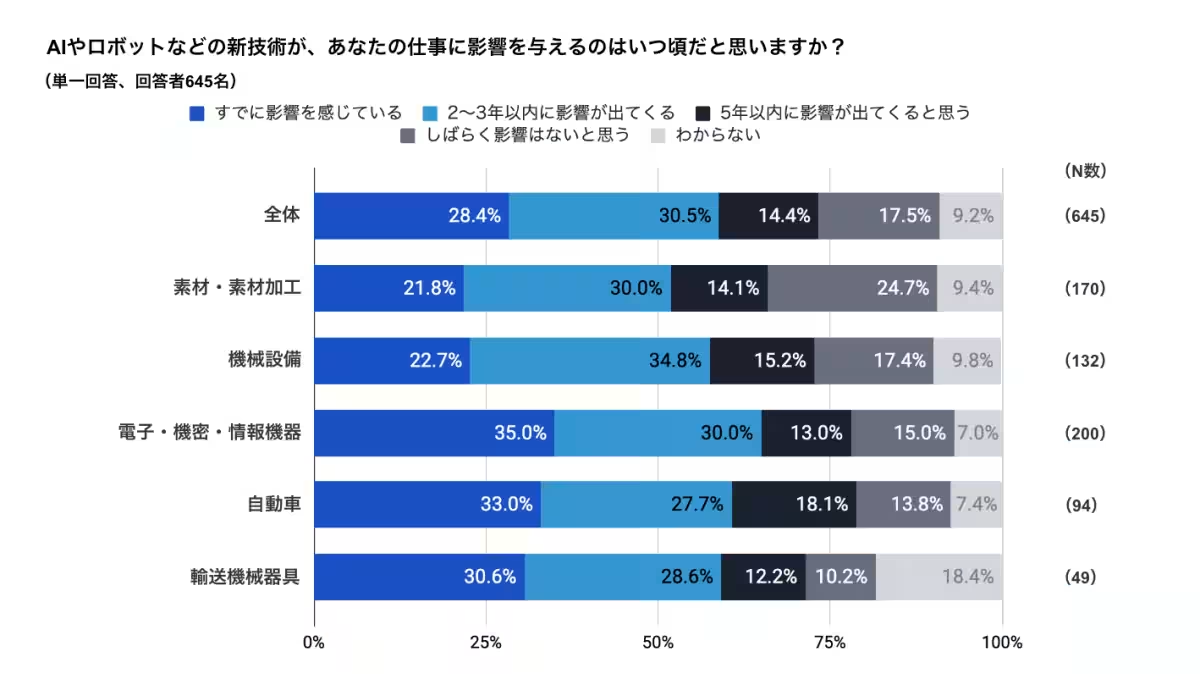

The Role of Technology

Simultaneously, a noteworthy shift is occurring with the increasing importance of AI and robotics within the industry. Around 60% of respondents acknowledged currently feeling the impact of these technologies or expecting changes within the next few years. Notably, executives from the electronic and precision equipment sectors felt these shifts more acutely compared to those in raw materials processing industries.

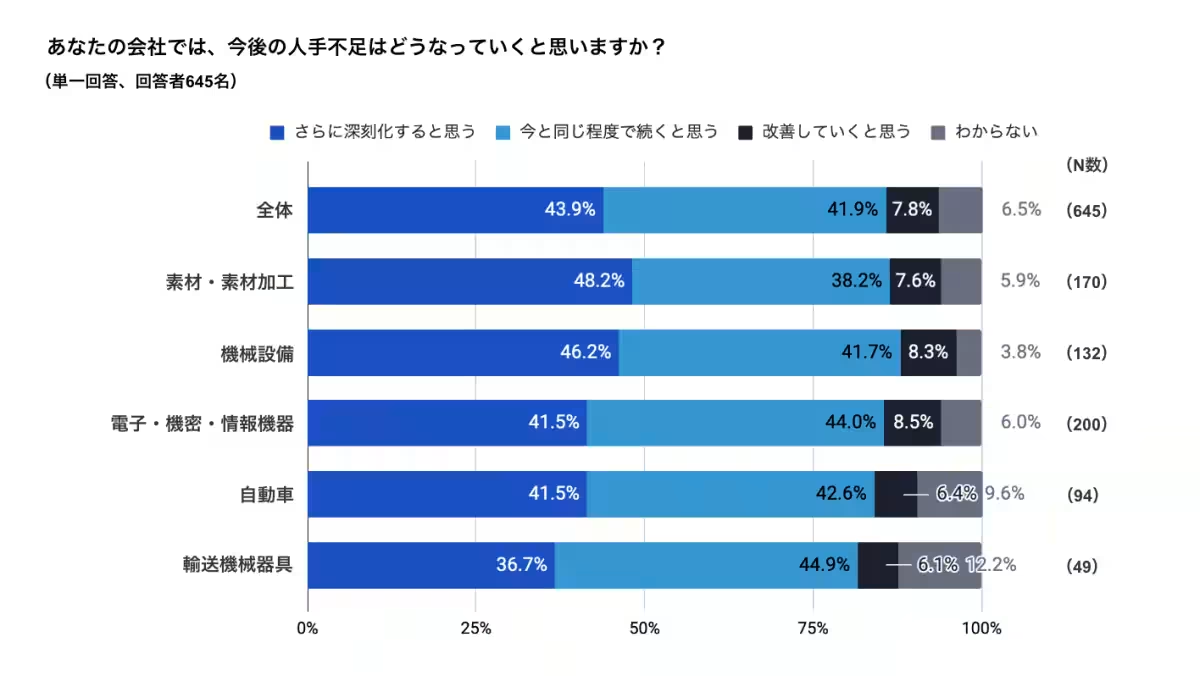

Preparing for Workforce Changes

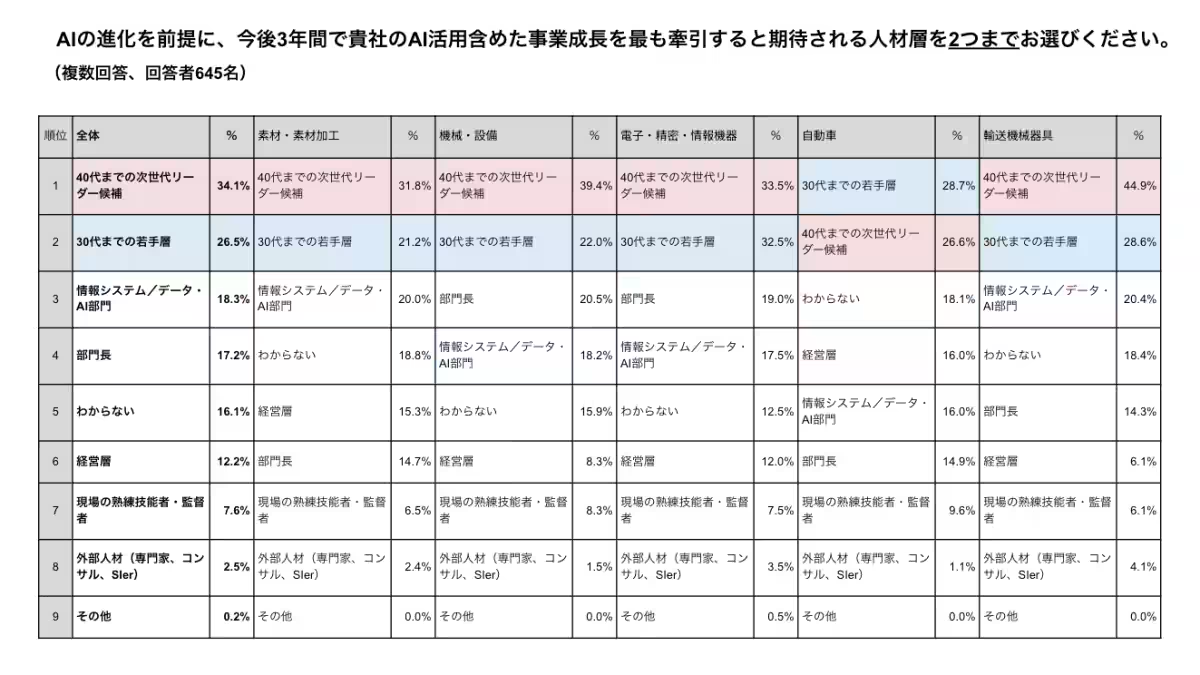

As the labor shortage looms large, more than 80% of those surveyed expect it to deepen over the next three years. This acknowledgment points to a need for innovative solutions in workforce management. The expected rise in reliance on next-generation leaders and younger workforce members is strong, with 34.1% citing 40s and younger candidates as potential leaders of technological advancement, alongside 26.5% for those in their 30s.

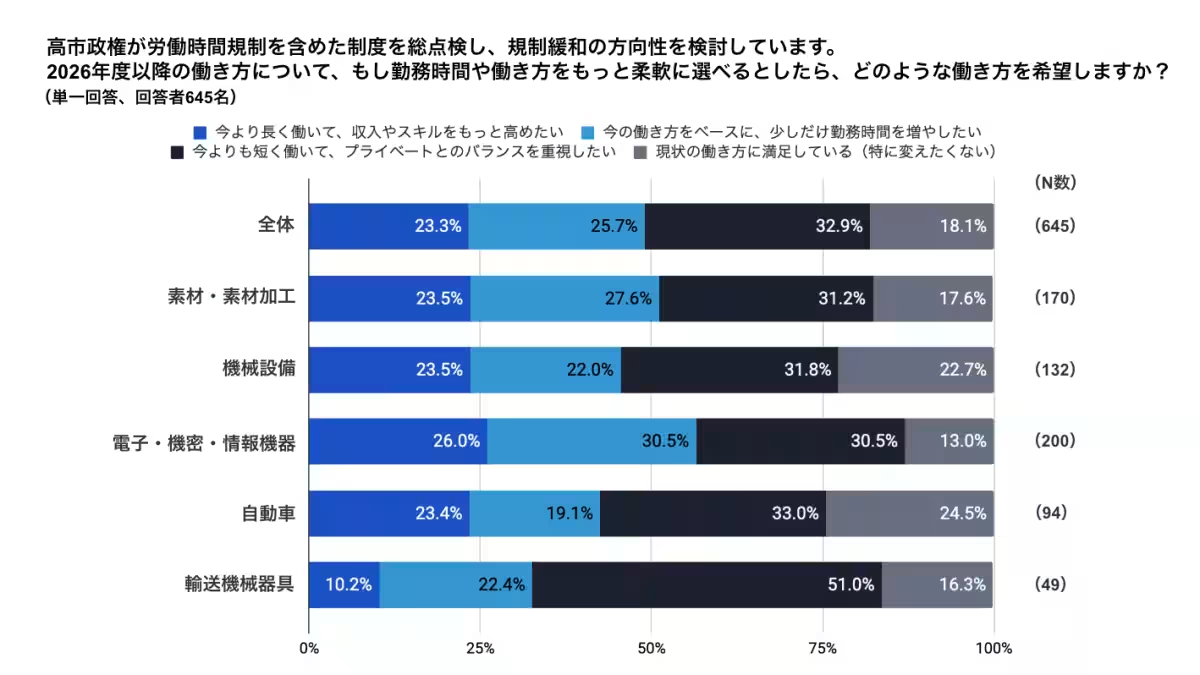

Shifting Work Attitudes

Interestingly, the workforce is also expressing a desire to work longer—with 49.0% stating they wish to extend their working hours as compared to 32.9% who prefer to work less. This shift in employee preferences may influence corporate policies and operational strategies moving forward.

Skills for the Future

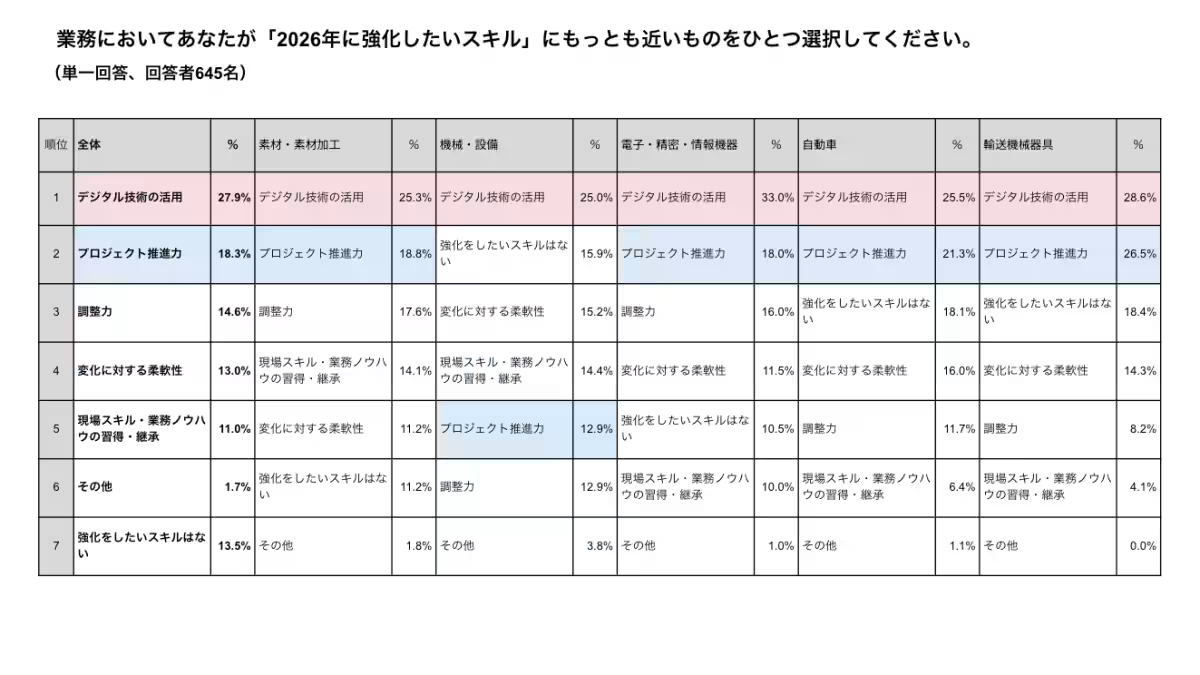

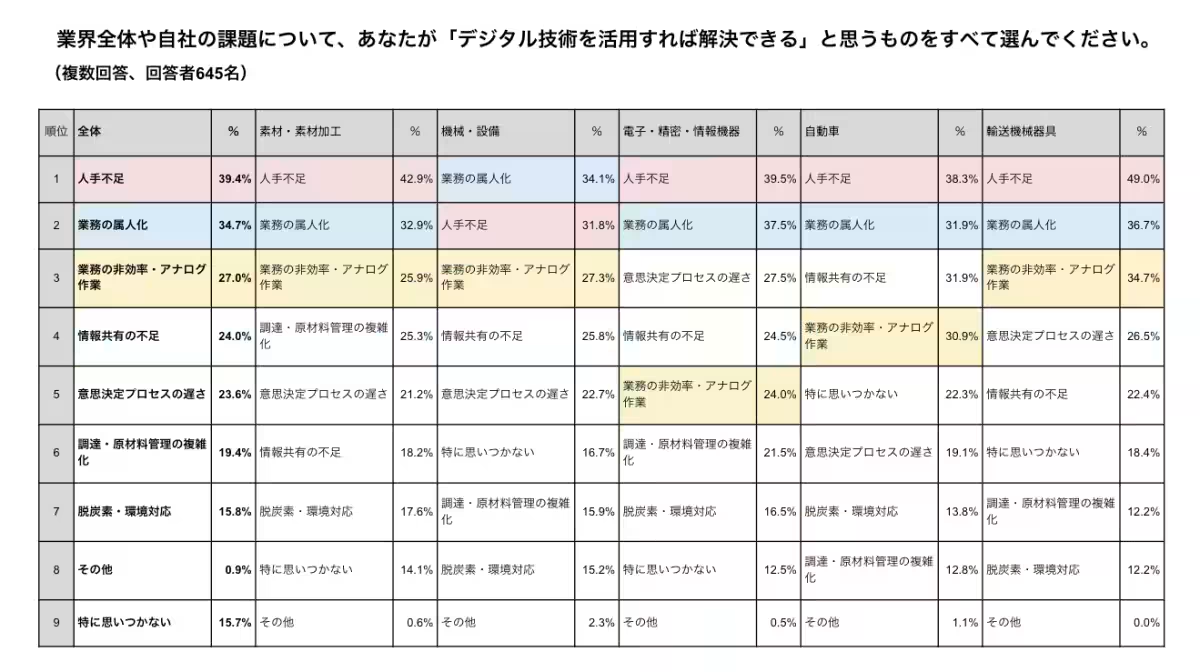

Enhancing digital skills remains the top priority across all sectors, with nearly 25% of respondents wanting to bolster their digital expertise. Digital technology is consistently being recognized as a means to address significant issues like labor shortages (39.4%) and the personalizing of tasks within organizations (34.7%). The emphasis on leveraging technology indicates a shift towards more streamlined operational approaches.

Conclusion: Navigating the Future of Manufacturing

The complexities revealed in this survey illustrate that the manufacturing industry is facing multiple simultaneous challenges. The interlinked issues of supply chain stability, labor shortages, and the critical integration of advanced technologies such as AI are reshaping operational landscapes. As manufacturers prepare for a future where these elements coexist, the role of digital transformation will be crucial to establishing resilience and operational efficiency.

For companies within this ecosystem, the path forward may involve not just responding to immediate concerns but also embracing the changes that technological advancements bring—creating a future-ready workforce prepared to thrive in an evolving landscape. CADDi aims to support this transformation by providing AI-driven data platforms designed to help harness new potentials within the manufacturing sector.

Company Overview

Founded in November 2017, CADDi Inc. is on a mission to unleash the potential of the manufacturing industry by creating AI-driven data platforms that facilitate efficiency and innovation in manufacturing. With operations spanning Japan, the USA, Vietnam, and Thailand, CADDi is committed to enabling a global transformation in manufacturing practices.

For further information on CADDi and its offerings, please visit CADDi Website.

Topics Other)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.