Punch Industry Corporation Makes Major Move into Laboratory Automation to Combat Labor Shortages

these tasks account for approximately 60% of actual work time in research and analysis. By industrializing laboratory practices, this technology enables researchers to concentrate on more advanced analyses and ideas.

In the West, the adoption of laboratory automation is progressing rapidly; however, in Japan, many researchers lack knowledge about automation equipment. The market is largely focused on off-the-shelf products with few manufacturers available for consultation from the conceptual stage. Punch Group aims to fill this gap by leveraging its know-how from the FA sector to provide tailored automation systems starting from the initial discussions — even when specifications haven’t yet been finalized.

Founded in 1975, Punch Industry Corporation has established itself as a manufacturer of molded parts. With declining labor forces, the company has identified automation and labor-saving markets as significant growth potential. In 2022, it set FA as a new growth engine in its medium-term management plan. The company also acquired ASCe Co., a firm specializing in automation equipment design. Participation in exhibitions and a gradual increase in sales highlight Punch's commitment to this growth area. The long-term vision, "Vision 60," established in May 2025, positions the FA business to contribute to diverse societal needs.

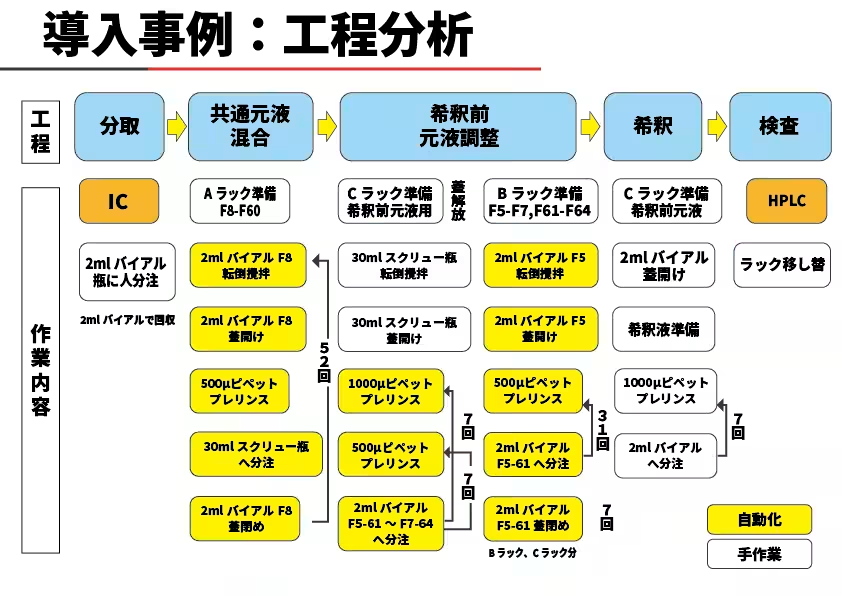

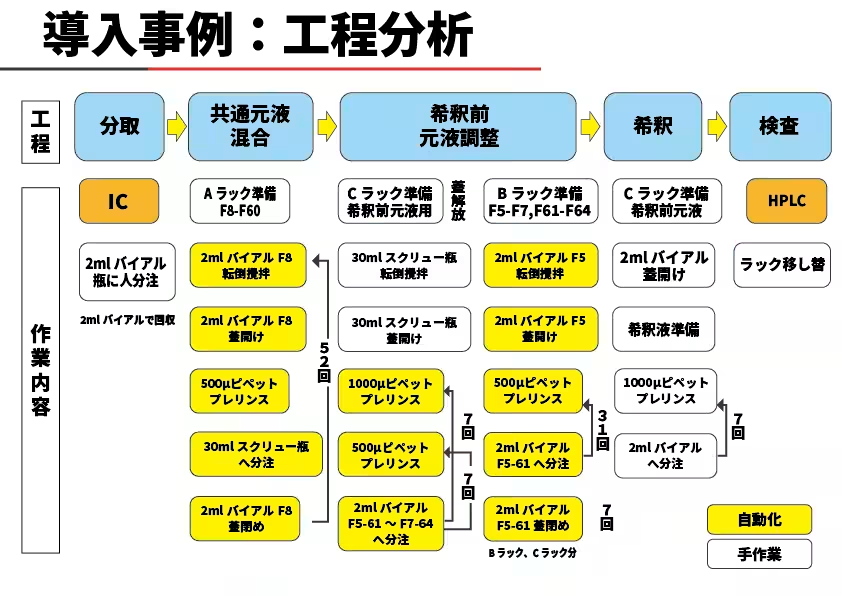

For projects where clients find it challenging to create specifications, Punch collaborates directly on-site to analyze experimental and analysical processes from an FA perspective. This joint definition of requirements helps bridge the gap between researchers' expertise and FA technical knowledge. All aspects from process analysis to system design and manufacturing are supported consistently.

One notable offering, Punch’s automated dispensing system, can be customized to accommodate the pipettes and tools used by clients. This allows customers to calibrate precision on their own, reducing operational burdens. Various modules can be added or modified according to client specifications, enabling flexible automation solutions.

*Examples of modules available for Punch's automated dispensing system include:

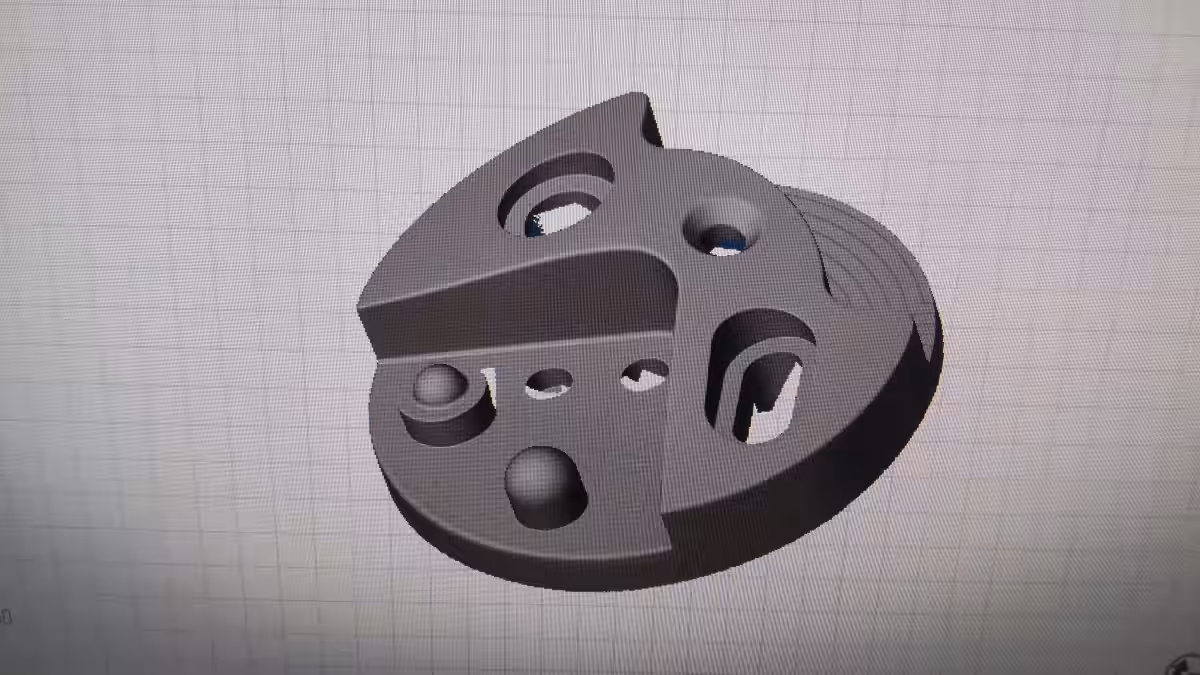

By designing simple mechanisms for each processing module and transport systems, Punch seeks to achieve an optimal balance between cost and performance. With 50 years of experience in manufacturing precision components, Punch designs and produces necessary fixtures and custom parts in-house, ensuring reliable supply.

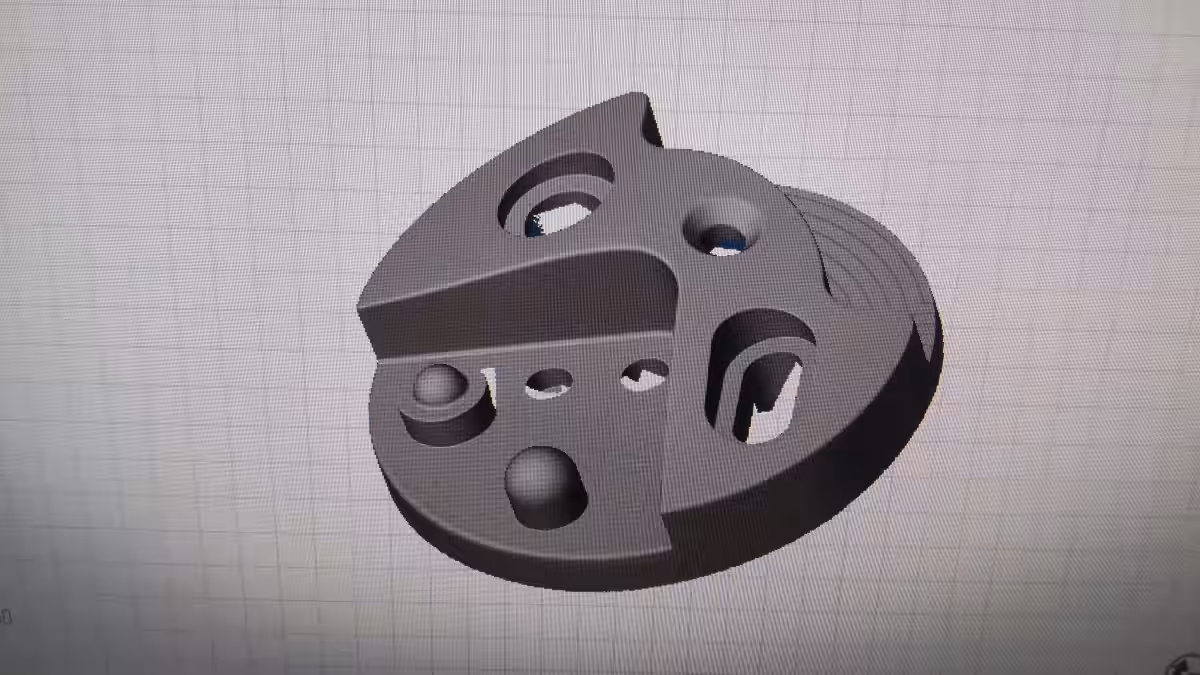

Utilizing 3D measurement technology, Punch also provides maintenance services to supply consumables for existing equipment. Scanning physical items with 3D scanners allows for seamless CAD drafting and part fabrication. Solutions to existing equipment maintenance issues — such as high costs and long lead times for replacement parts — are also offered. Proposals for cost reductions in device maintenance on-site and production improvements are within their scope.

Punch is actively showcasing demonstration machines for their automated dispensing system, allowing real-time functionality checks. The systems perform various operations, including sample agitation, capping, and dispensing. Their image recognition capabilities enable the opening of multiple tube types effectively. Interested parties can contact Punch for further inquiries regarding demonstrations.

For detailed case studies, please visit the designated website.

The name "Punch" reflects the company's original product, a punch for drilling holes in printed circuit boards, signifying both impact and vigor. The company logo, featuring a fist, symbolizes both their product line and their dynamic presence in the industry, demonstrating intentions to innovate within the market.

For inquiries, please reach out to Punch Industry Corporation's FA Division via email at [email protected] or visit their website at Punch FA.

Background for Punch Group's Entry into LA

In the West, the adoption of laboratory automation is progressing rapidly; however, in Japan, many researchers lack knowledge about automation equipment. The market is largely focused on off-the-shelf products with few manufacturers available for consultation from the conceptual stage. Punch Group aims to fill this gap by leveraging its know-how from the FA sector to provide tailored automation systems starting from the initial discussions — even when specifications haven’t yet been finalized.

Punch Group’s Automation Business

Founded in 1975, Punch Industry Corporation has established itself as a manufacturer of molded parts. With declining labor forces, the company has identified automation and labor-saving markets as significant growth potential. In 2022, it set FA as a new growth engine in its medium-term management plan. The company also acquired ASCe Co., a firm specializing in automation equipment design. Participation in exhibitions and a gradual increase in sales highlight Punch's commitment to this growth area. The long-term vision, "Vision 60," established in May 2025, positions the FA business to contribute to diverse societal needs.

Strengths of Punch Group's LA Business

Comprehensive Support from Conceptualization to Implementation

For projects where clients find it challenging to create specifications, Punch collaborates directly on-site to analyze experimental and analysical processes from an FA perspective. This joint definition of requirements helps bridge the gap between researchers' expertise and FA technical knowledge. All aspects from process analysis to system design and manufacturing are supported consistently.

Customizable Devices for Unique Needs

One notable offering, Punch’s automated dispensing system, can be customized to accommodate the pipettes and tools used by clients. This allows customers to calibrate precision on their own, reducing operational burdens. Various modules can be added or modified according to client specifications, enabling flexible automation solutions.

*Examples of modules available for Punch's automated dispensing system include:

- - Dilution processes

- - Solution preparation

- - Weight measurement

- - Barcode reading

- - Tube image recognition

- - Cap opening

- - Agitation, vibration, and ultrasonic cleaning

- - Heating and cooling

- - Solid phase extraction

Optimal Cost Performance

By designing simple mechanisms for each processing module and transport systems, Punch seeks to achieve an optimal balance between cost and performance. With 50 years of experience in manufacturing precision components, Punch designs and produces necessary fixtures and custom parts in-house, ensuring reliable supply.

Maintenance Services for Consumables

Utilizing 3D measurement technology, Punch also provides maintenance services to supply consumables for existing equipment. Scanning physical items with 3D scanners allows for seamless CAD drafting and part fabrication. Solutions to existing equipment maintenance issues — such as high costs and long lead times for replacement parts — are also offered. Proposals for cost reductions in device maintenance on-site and production improvements are within their scope.

Demonstration Machines Available in Tokyo

Punch is actively showcasing demonstration machines for their automated dispensing system, allowing real-time functionality checks. The systems perform various operations, including sample agitation, capping, and dispensing. Their image recognition capabilities enable the opening of multiple tube types effectively. Interested parties can contact Punch for further inquiries regarding demonstrations.

Case Studies in the LA Sector

- - Automation of preprocessing in HPLC, reducing workloads by two people for 16 hours daily and enhancing accuracy.

- - Automation of organic synthesis processes in material development and drug discovery.

- - Preprocessing automation for analytical equipment like HPLC and ICP.

- - Automation of bio-product (antibody purification) manufacturing and contracted sample preprocessing.

For detailed case studies, please visit the designated website.

Punch Industry Corporation Overview

- - Name: Punch Industry Corporation

- - CEO: Teiji Morikubo

- - Location: 5th Floor, Omori Bellport E Building, 6-22-7 Minamiooi, Shinagawa-ku, Tokyo

- - Listing: Tokyo Stock Exchange Standard Market (6165)

- - Established: 1975

- - Revenue: ¥40.8 billion (consolidated) for FY2025

- - Employee Count: 3,463 (consolidated by March 2025)

- - Corporate website: Punch Website

- - Official YouTube Channel: Punch YouTube

Company Mission and Logo

The name "Punch" reflects the company's original product, a punch for drilling holes in printed circuit boards, signifying both impact and vigor. The company logo, featuring a fist, symbolizes both their product line and their dynamic presence in the industry, demonstrating intentions to innovate within the market.

Contact Information

For inquiries, please reach out to Punch Industry Corporation's FA Division via email at [email protected] or visit their website at Punch FA.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.