Sirius Japan Revolutionizes Logistics with AMRs at STOCKCREW's New Facility in Chiba

Sirius Japan Launches AMRs at STOCKCREW's Chiba Dock2

In a significant development for the logistics sector in Japan, Sirius Japan Co., Ltd., a leading provider of Autonomous Mobile Robots (AMRs), has announced the introduction of 15 units of its FlexSwift series at STOCKCREW’s new logistics hub, Chiba Dock2. This move is expected to bolster operational efficiency and support the rapid growth of e-commerce logistics.

Background and Purpose of the AMR Introduction

The decision to deploy the FlexSwift series stems from STOCKCREW’s commitment to standardizing its logistics infrastructure and maximizing human capabilities in operations. This initiative aims to enhance the logistics handling capacity in response to the increasing and diverse needs of e-commerce businesses.

As the e-commerce market continues to expand, logistics providers face the common challenge of improving operational efficiency. Particularly, small and medium-sized e-commerce businesses are increasingly seeking logistics outsourcing solutions, paving the way for STOCKCREW's impressive growth as a logistics service provider. From its inception, the company has focused on establishing standardized operational flows that do not rely on specific skilled workers, while designing operations with robots at the forefront.

Why STOCKCREW Chose the FlexSwift Series

The selection of Sirius Japan’s AMR was not merely a response to labor shortages, but rather a shared philosophy of enhancing human capabilities. This alignment with STOCKCREW’s strategy includes:

1. Exceptional Scalability and Flexible System Architecture: STOCKCREW operates on the principle of expanding warehouse sections based on standardized operations. Unlike other AMRs that require compartmentalization after reaching a certain scale, Sirius's AMRs can operate autonomously while sharing information, theoretically allowing unlimited scalability. This flexibility enables the business to smoothly expand physical warehouse space and increase AMR deployment in as little as three days.

2. Simple Implementation and Rapid Expansion Capability: The FlexSwift series does not require complex fixed facilities or networking installations, allowing for stable operation even in environments with limited communication infrastructure, such as pocket Wi-Fi or smartphone tethering. President Nakamura remarked on past challenges with infrastructure setups not keeping pace with expansion needs, underscoring the importance of having AMRs that could quickly and flexibly adapt to operational demands.

Achievements from FlexSwift Series Implementation at Chiba Dock

The implementation of the FlexSwift series at STOCKCREW’s Chiba Dock1 (which sees up to 110 Sirius AMRs in operation) has yielded impressive operational efficiencies, including:

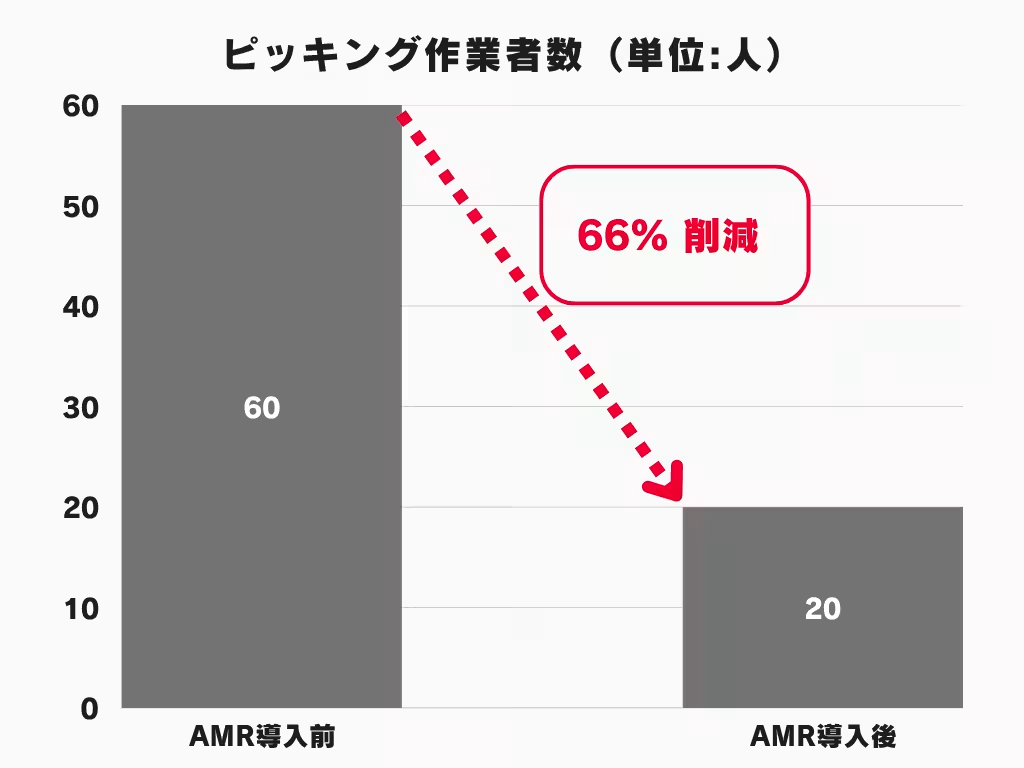

1. 66% Reduction in Picking Workforce: The introduction of the FlexSwift series has enabled warehouse operations that previously required 60 picking workers to operate with just 20.

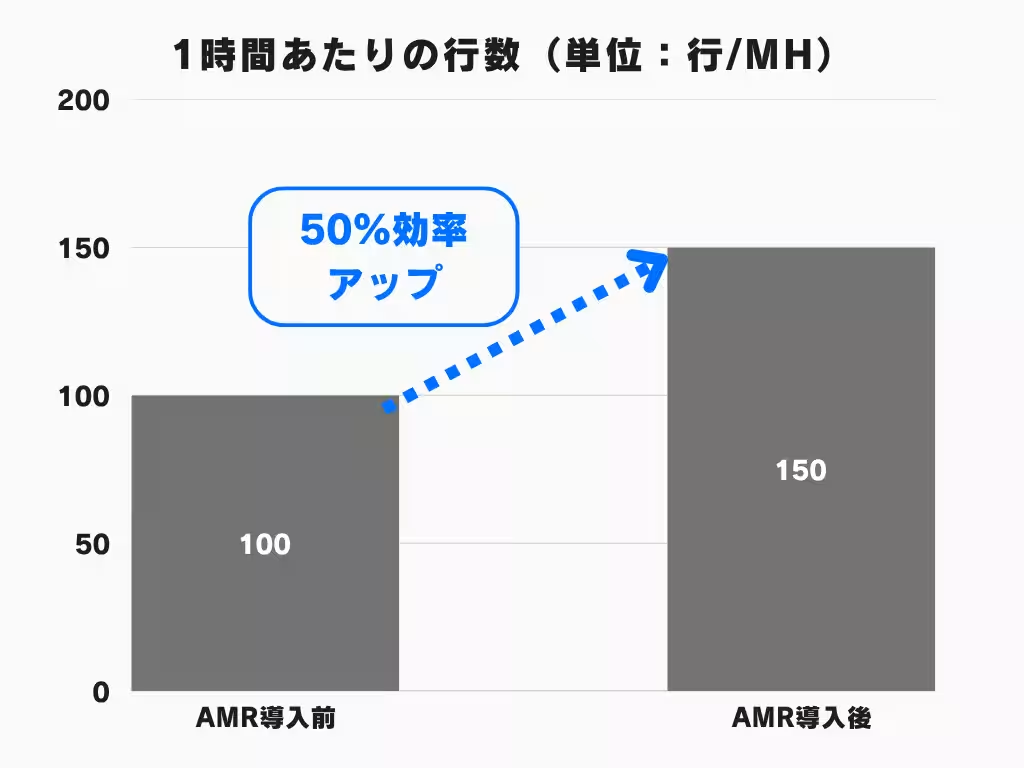

2. 50% Increase in Processing Volume: There has been a 50% increase in hourly processing volumes compared to manual-only methods, significantly boosting productivity.

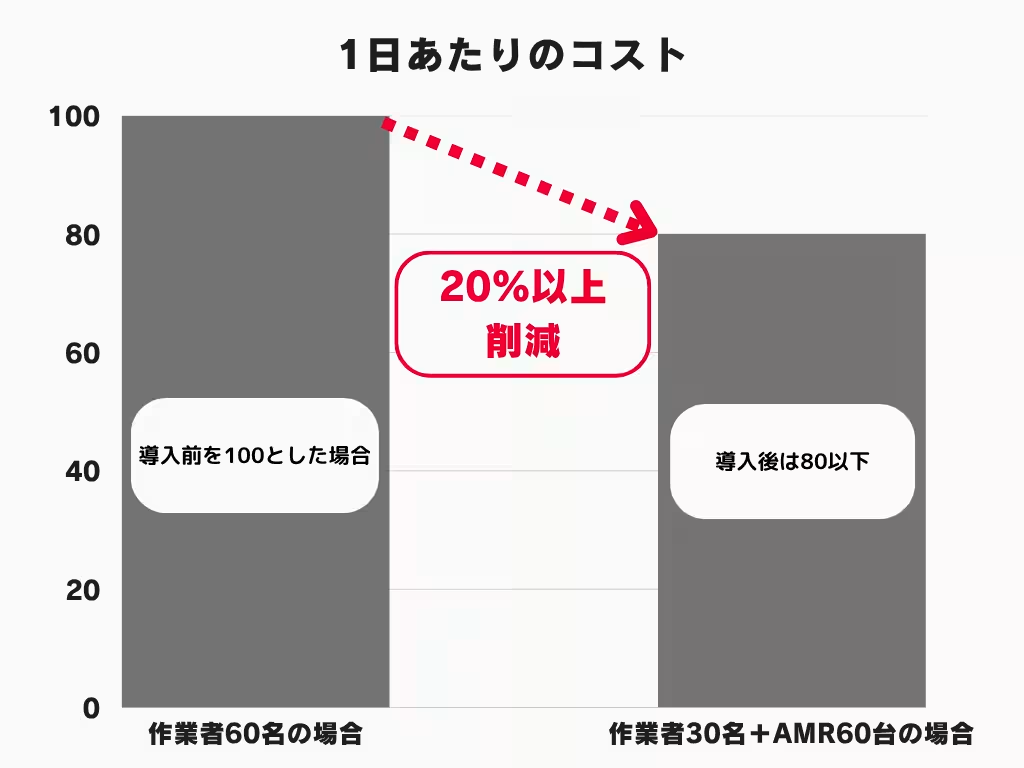

3. Over 20% Reduction in Overall Costs: Comparing operations staffed by 60 workers to a setup with 30 workers and 60 AMRs demonstrated a reduction in monthly warehouse operational costs of over 20%.

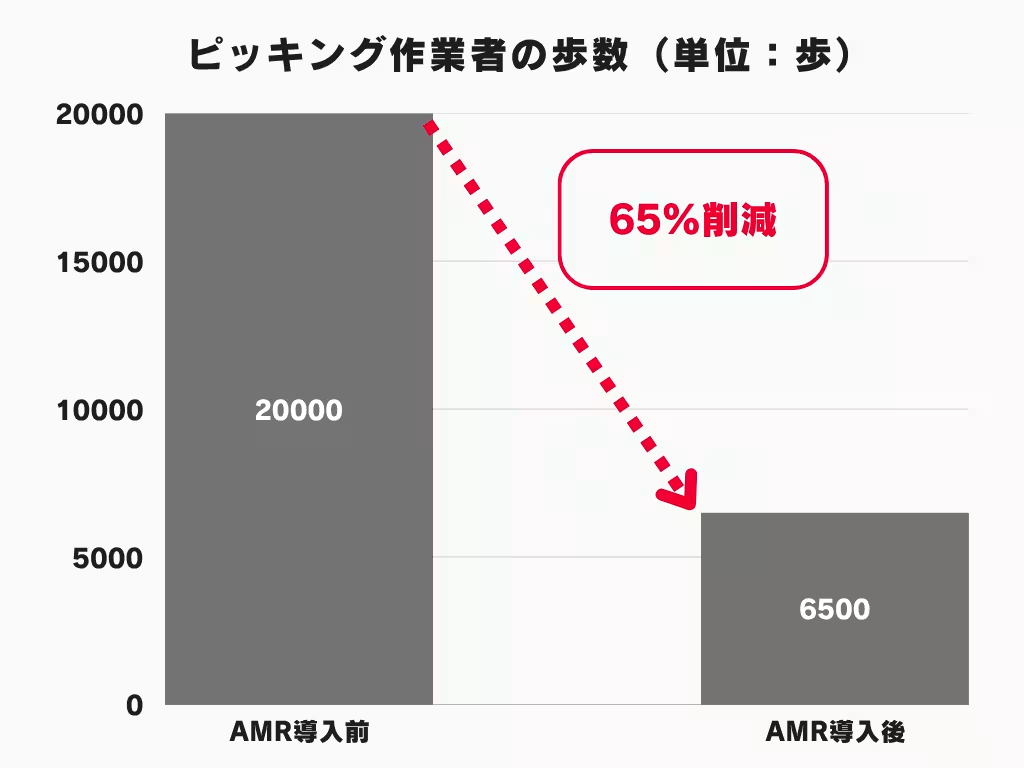

4. 65% Decrease in Average Movement Distance: The average daily walking distance for picking workers has been cut from approximately 20,000 steps to about 6,500, thanks to the combination of AMRs and zone picking. This substantial reduction in physical strain promotes a more conducive working environment.

Comments from President Nakamura of STOCKCREW

“The primary reason we chose Sirius Japan's AMRs is their philosophy of enhancing human abilities, along with their sophisticated software technology and remarkable scalability that keeps pace with business growth. The flexibility of the FlexSwift series, allowing for stable operation in restrictive communication environments without cumbersome setup changes or large-scale construction, was invaluable when establishing our logistics locations. The introduction of these 15 units will strengthen our existing standardized operations and significantly improve our service quality to our customers,” Nakamura stated.

Sirius Japan's Commitment to the Future

Sirius Japan intends to strengthen collaborations with innovative logistics service providers like STOCKCREW, delivering cutting-edge AMR solutions that contribute to the industry’s evolution. The FlexSwift series supports seamless integration, operational flexibility, and a high return on investment, facilitating logistics problem-solving effectively.

About the FlexSwift Series

The FlexSwift, developed by Sirius Robotics, is an AMR specifically designed to enhance efficiency in picking operations within logistics environments, capable of carrying loads up to 100 kg. It utilizes existing Wi-Fi networks, allows for integration without halting ongoing operations, and operates using CSV/Excel data. Additionally, the company offers a Robotics as a Service (RaaS) model, including comprehensive support from setup to maintenance, enabling adjustment according to logistics fluctuations.

Company Overviews

Sirius Japan is the Japanese subsidiary of Sirius Technology, founded in 2018, focused on providing comprehensive support for AMR solutions in Japan. STOCKCREW, based in Tokyo, is a logistics service provider that supports the growth of small and medium e-commerce businesses through innovative solutions and advanced technologies.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.