Secrets of Young Workforce: Innovations at Takara Industries and Takara Resin Industry

Takara Industries and Takara Resin Industry: Pioneering Young Talent in Manufacturing

In the prominent area of Aoi, Adachi-ku, Tokyo lies a sprawling market for innovation and manufacturing, house to two influential firms—Takara Industries and Takara Resin Industry. With an impressive 1,300-tsubo facility, this dynamic duo has carved a niche, focusing on both metal and plastic processing. We're diving deeper into their operational strategies, especially how they empower a young workforce, with insight from Tomofumi Anjiki, the Vice President.

Broad Range of Capabilities: From Metal to Plastic Processing

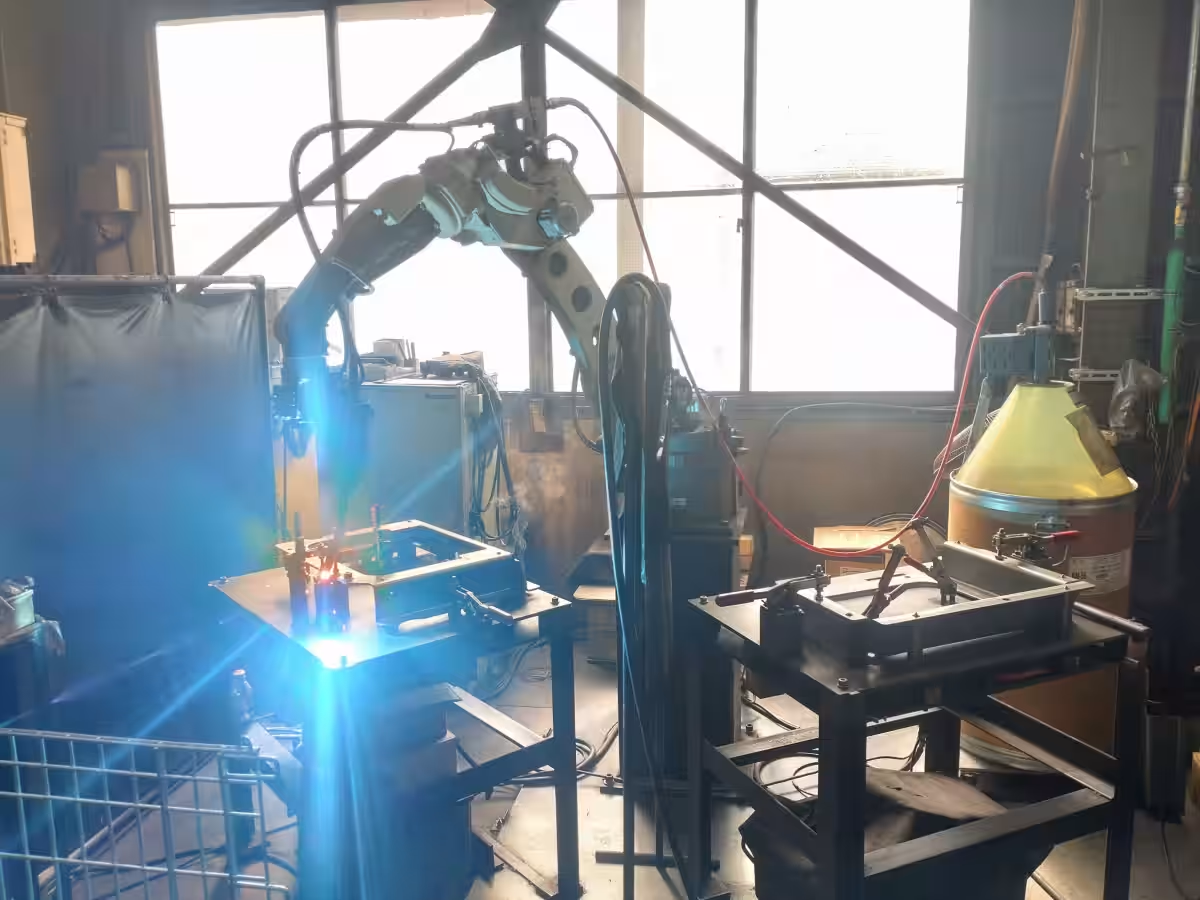

Founded shortly after World War II in Sumida, Takara Industries began as a domestic electric appliance manufacturer and has grown into a major player in precision parts manufacturing, handling metal processing alongside various components such as cutting, welding, and injection molding. After relocating to Aoi in 1952, their legacy now spans over 72 years.

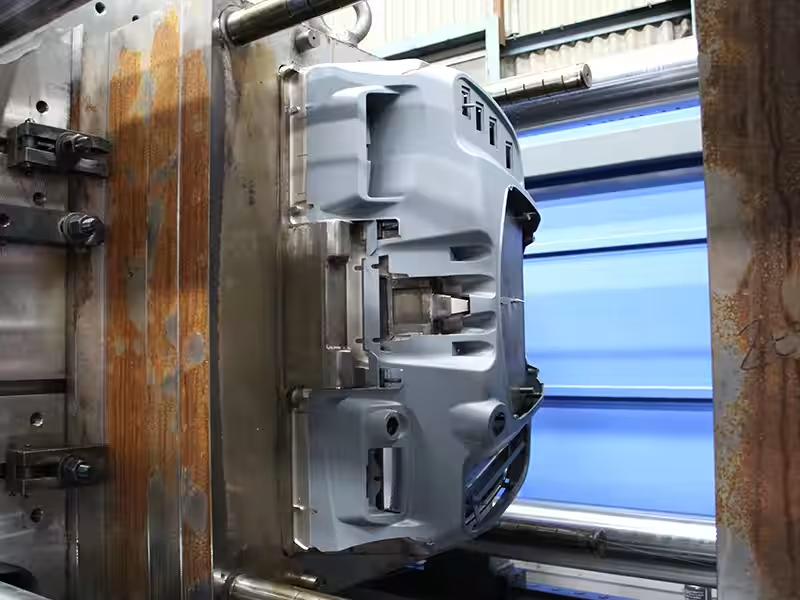

On the other hand, Takara Resin Industry emerged in the 1980s when the current president, Yoshitaka Kaibou, returned from Brazil with a vision to meet the growing market for automotive plastic parts. This foresight led to the creation of numerous successful components, notably in airbags and other automotive necessities.

With a robust background in diverse manufacturing techniques, the companies have launched revolutionary products like spring seals for shipping containers and rubber springs for trains, consistently enhancing industrial standards through innovation.

Fostering Local Identity and Collaboration: The Adachi Brand

Recognized as a member of the Adachi Brand in 2015, the companies benefit from collaborative opportunities and marketing exposure. Adjacent to many historic factories, the area has transformed, making it crucial for industries to evolve and adapt. Anjiki mentions how engaging in the 'Adachi Brand' initiative opened avenues for exhibitions and local engagement, significantly benefiting their business strategy.

“We were struggling with our environmental and marketing approach, and I discussed this with the president of a partnering metal processing factory. The Adachi Brand initiative was an outgrowth of that discussion and became a pivotal point for us,” he explains. The active participation in trade shows has yielded promising contracts, notably with major manufacturers in diverse sectors, thereby fortifying their business.

A Comprehensive Approach to Manufacturing

Their extensive facility is equipped with advanced machinery, including six machining centers and injection molding machines that cater to a wide range of specifications (100t, 350t, and 450t). This integration allows seamless coordination from design to delivery, showcasing their commitment to quality and speed.

“We pride ourselves on not only adhering to cost efficiency and short lead times but on also ensuring each phase of production is meticulously managed internally. From concept through design and materials selection to final manufacturing, we strive for excellence,” Anjiki articulates.

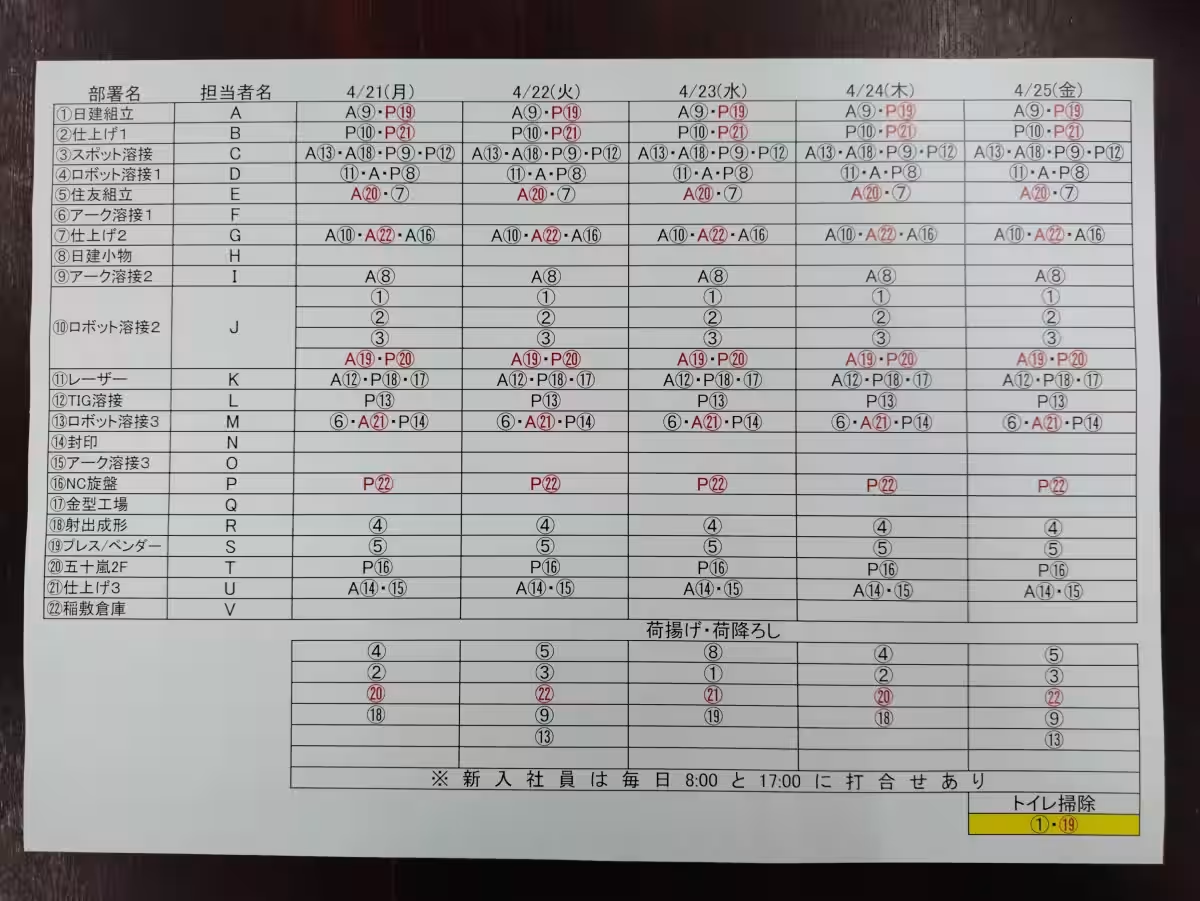

Each team member, regardless of their specific role, is encouraged to engage with various machinery and techniques to foster a deeper understanding of the production process. This policy assists with skill development but also aids in addressing capacity challenges as workforce needs shift across departments.

Commitment to Workforce Development and Diversity

An impressive fact about the two companies is that 75% of their workforce comprises individuals in their 10s to 30s, reflecting an invigorated culture that is both vibrant and diverse. Emphasizing a youthful workforce's importance, Anjiki remarked, "We’re focusing on creating an inviting environment for aspiring professionals, including women, as we have gradually seen an increase in female applicants."

Employing tactics such as internship programs, Takara Industries aims to prioritize fresh graduates, enhancing creativity and skill diversity while retaining core values. They also adopt a rotation policy whereby employees switch between tasks each week, exposing them to all facets of production, thereby broadening their capabilities and adaptability. This structure not only strengthens team synergy but also speeds up the sharing of technical insights across the company.

Overcoming Challenges through Innovation

Despite the notable advancements and young talent integration, the journey has not been without obstacles. Anjiki highlights, “Talent retention and keeping pace with technology are key challenges. Our methodologies must continually adapt, especially as generational perspectives differ.” To address this, they have successfully transformed tacit knowledge into quantifiable processes, ensuring that skills are both preserved and amplified among employees.

Through collaboration and continuous feedback, the companies work tirelessly to find solutions to environmental challenges as well. Their commitment to sustainable practices, such as recycling and the development of eco-friendly products, echoes their ambition to lead through innovation while upholding industry standards and reducing environmental footprints.

The Future of Takara Industries and Takara Resin Industry

As they continue shaping their journey, both companies emphasize a philosophy of accessibility and partnership. Anjiki encourages clients to approach them with any manufacturing challenges, fostering a culture of open dialogue. Their mantra is to never turn down a project.

Furthermore, Takara Industries recognizes the significance of contributing positively to the community through initiatives within the 'Adachi Brand', striving to enhance local industry standards and uplift the community’s perception. This commitment extends beyond production, as they acknowledge that embracing challenges today sets the foundations for a more resilient enterprise tomorrow.

In conclusion, the powerful synergy between Takara Industries and Takara Resin Industry epitomizes not just successful manufacturing, but also the promise of innovation through youth engagement and community partnership—crafting a bright future ahead.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.