Next-Gen Piling Machines: The SX Series Launching in Spring 2024

Revolutionizing Construction with the SX Series

Giken Seisakusho Co., Ltd., headquartered in Kochi, Japan, is set to launch the innovative "SX Series" of piling machines beginning next spring. This latest addition to their renowned product line seeks to address the pressing challenges faced by the construction industry, particularly issues stemming from an aging workforce and a shortage of skilled workers.

The SX Series is designed to create a safer environment for even those with minimal experience to engage in construction activities. Integrated with Giken's cloud-based data platform, G-Lab™, the SX Series merges piling techniques with digital technology, paving the way for next-generation piling operations. Equipped with features such as automated driving and operator assist functions, the machines promise enhanced construction quality and reduced operator workloads.

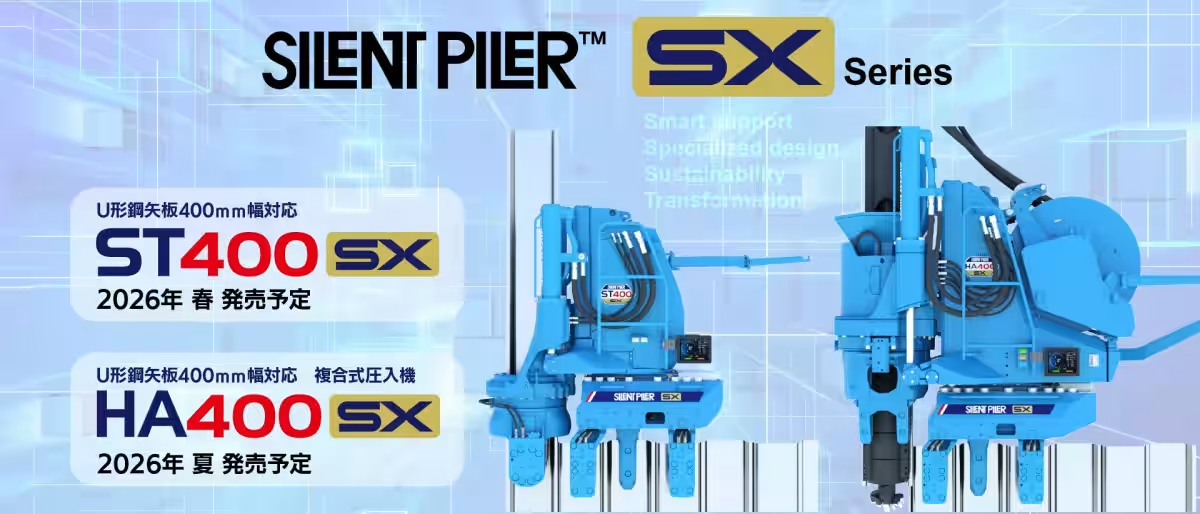

Among the new offerings, the first machine to hit the market will be the "Silent Piler™ ST400SX", suitable for U-shaped steel sheet piles with a width of 400 mm, scheduled for release next spring. Alongside this, Giken will also introduce the MUB150, a battery-powered electric power unit, which marks a significant step toward zero-emission piling operations.

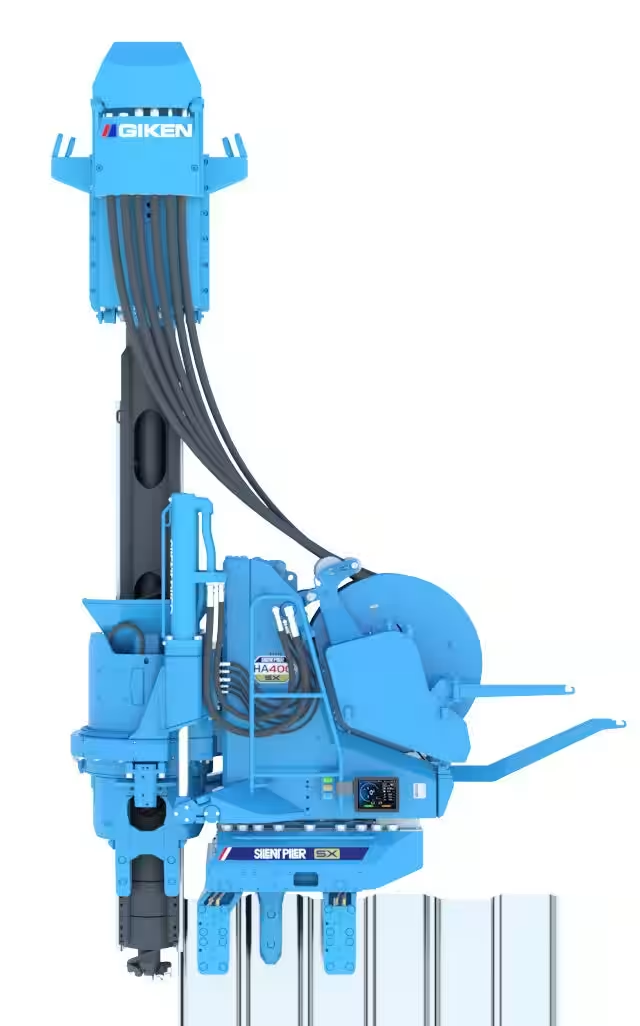

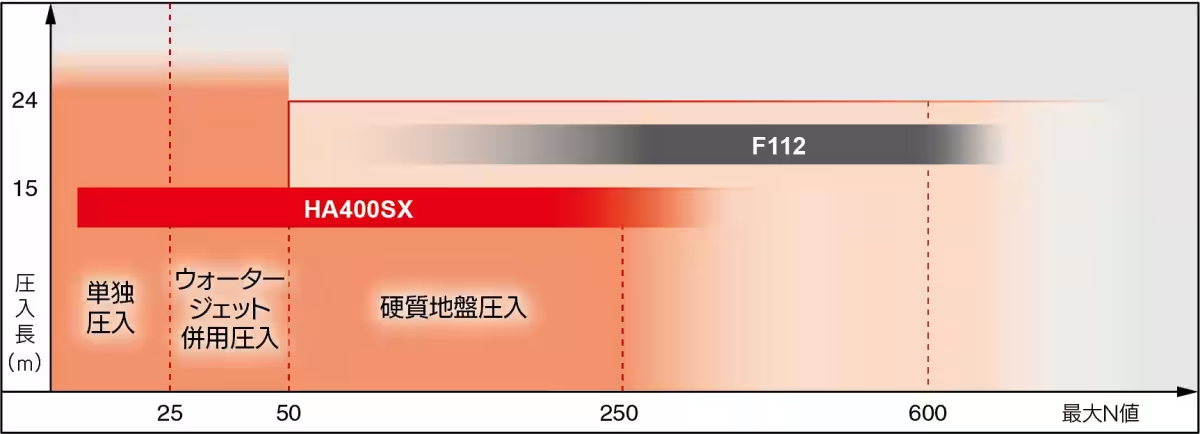

By summer 2024, the Silent Piler™ HA400SX, a complex machine compatible with solid ground, will also be available. Moving forward, Giken plans to introduce various models addressing a wide array of piling materials, ground conditions, and constraints.

Concept of the SX Series

The SX in the series name embodies three core values: Smart Support, Specialized Design, and Sustainability. The "S" represents the innovative automated driving and operation support that ensure stable construction quality while alleviating operator burden. The Specialized Design emphasizes optimally tailored machines for diverse worksite requirements while the Sustainability focus aims to reduce environmental impact and create an easily operable design for all users. The letter "X" signifies the transformation of the construction landscape.

Key Features of the SX Series

Smart Support — Automation and Operation Assistance

The SX Series automates the collection of piling data, including penetration resistance and required timing, storing it as digital data in the cloud. This data powers the automated operation assist app, G-Lab Nexus, which autonomously configures pressure input and speed settings based on collected data, allowing for consistent construction quality. By summer 2024, an AI-driven feature will suggest optimal automated driving based on prior data.

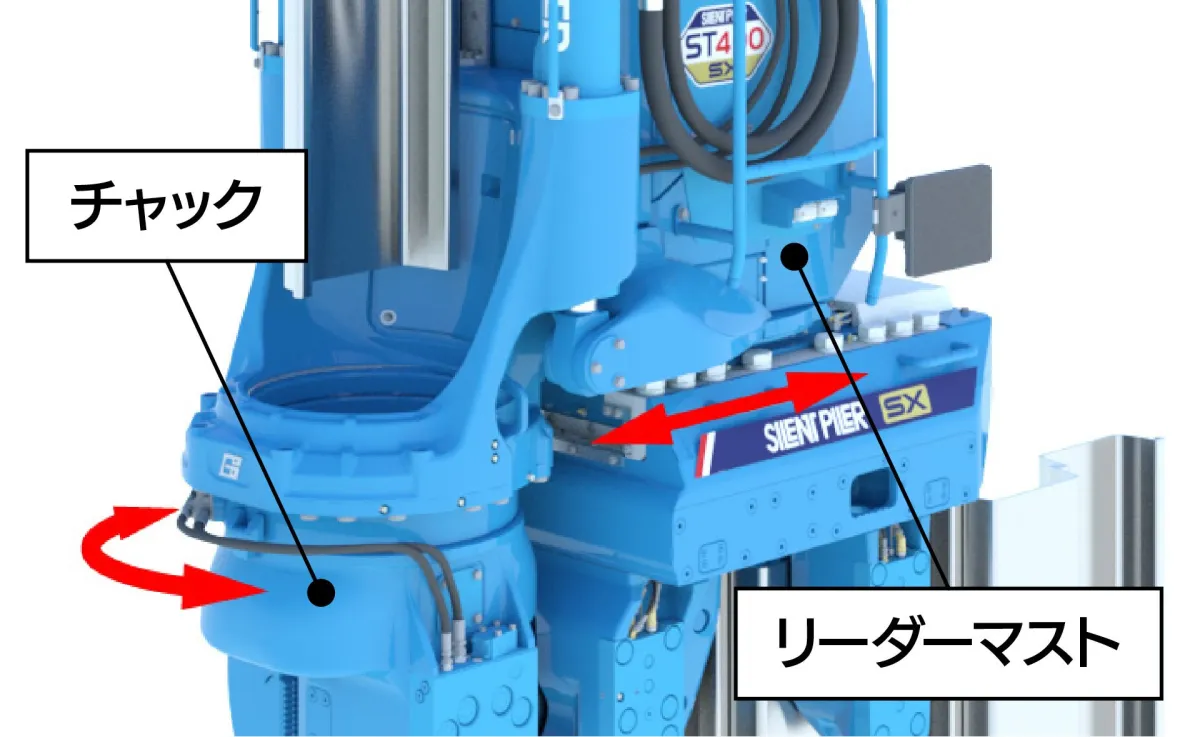

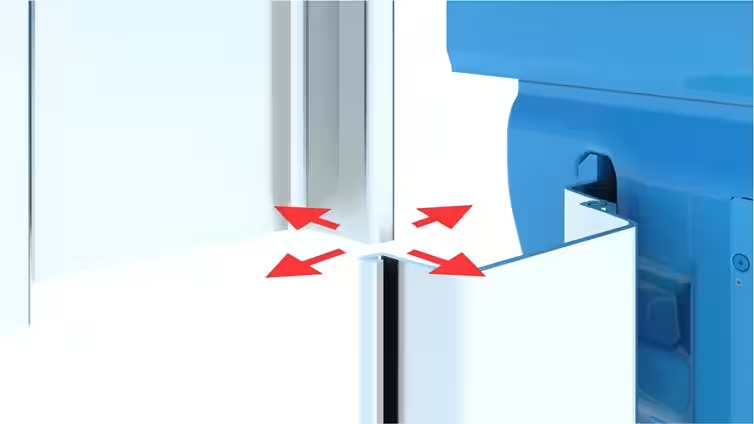

Furthermore, the machines include a one-touch automation function that allows for easy self-operation. They assist with various tasks such as pile placement, coupler alignment, and lid adjustment, streamlining standard operating procedures and minimizing operator fatigue while enhancing safety by reducing the risk of human error.

Specialized Design — Optimization for Various Conditions

Each machine in the SX Series is meticulously engineered to meet the specific conditions of its worksite, balancing efficiency and stability to cater to diverse construction needs. These models include lightweight machinery suitable for urban and constrained spaces, as well as machines that handle multiple installation methods for various ground types.

Sustainability — Enhancing Environmental Responsibility

The adoption of battery-powered units enables the SX Series to achieve CO₂-emission-free piling operations. As the workforce ages, the proactive accumulation of piling data will facilitate future AI learning and automated construction systems, fostering sustainable skills transfer. The automation and operational assistance functions empower even inexperienced workers, thus promoting a sustainable operational framework.

The Silent Piler™ ST400SX

This model is designed to efficiently handle U-shaped steel sheet piles with a width of 400 mm. Compared to its predecessor, the Silent Piler™ F101, the ST400SX weighs 200 kg less and boasts enhanced extraction capabilities with an increased pulling force of 100 kN. This improved model ensures rapid responsiveness, with cycle times for pile insertion and extraction reduced by approximately 37%. Notably, it accommodates the new battery-powered units, enabling operations with zero emissions.

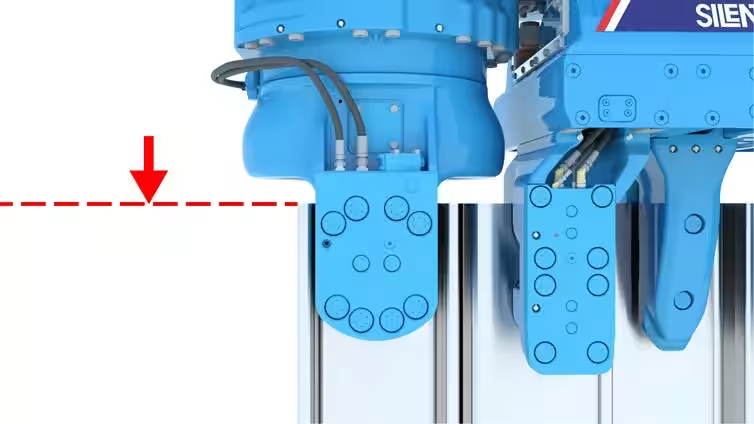

The Silent Piler™ HA400SX

This versatile machine allows for three piling methods: standalone, water-jet assisted, and for solid grounds. Its design focuses on lightweight and compact dimensions, making it ideal for layers of gravel or stone with high demand due to ground hardness. Not only does it weigh significantly less than its comparable models, but it also meets the operational demands prevalent in the industry today.

Battery Electric Power Unit MUB150

The MUB150 serves as a power source for the Silent Piler™ ST400SX, utilizing electric motors instead of diesel engines. With zero emissions, this battery-operated unit requires no external power sources and significantly expands the possibility for zero-emission piling sites. Its low noise level significantly exceeds the legal noise limits, making it an ecological and effective choice for contemporary constructions.

G-Lab™ Data Platform

G-Lab™ consolidates various construction-related data on a cloud platform, allowing for systematic analysis and utilization of piled-up information to enhance decision-making in the field. With the introduction of G-Lab Nexus, along with existing applications, Giken continues to optimize and streamline construction processes.

Giken remains committed to building a safe and sustainable future through innovation in technology and unwavering dedication to enhancing the construction landscape. As the company approaches the 50th anniversary of the Silent Piler™, the SX Series represents a bold step forward in transforming construction practices to meet societal needs while ensuring continuous improvement and sustainability.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.