Eco-friendly 'L・DieL®' Stainless Steel Revamps Manufacturing with Reduced Wear and Environmental Benefits

Revolutionizing Manufacturing with Eco-Friendly Solutions

Japan's Nihon Kinzoku Co., headquartered in Minato-ku, Tokyo, has taken a significant step forward in sustainable manufacturing with the launch of its new eco-friendly product, L・DieL® (Long Die Life). This stainless steel solution is designed to minimize mold wear during the press processing stage, thereby enhancing production efficiency and reducing costs for customers.

Understanding L・DieL®

The main innovation behind L・DieL® lies in its unique surface treatment that modifies the passive oxide film, primarily composed of chromium oxide, which typically hardens onto stainless steel surfaces. While this oxide layer is crucial for corrosion resistance, it can also accelerate wear during repetitive contact in manufacturing. The L・DieL® process softens this oxide layer, significantly lowering mold wear and extending the lifespan of metal mold tools.

Key Features of L・DieL®

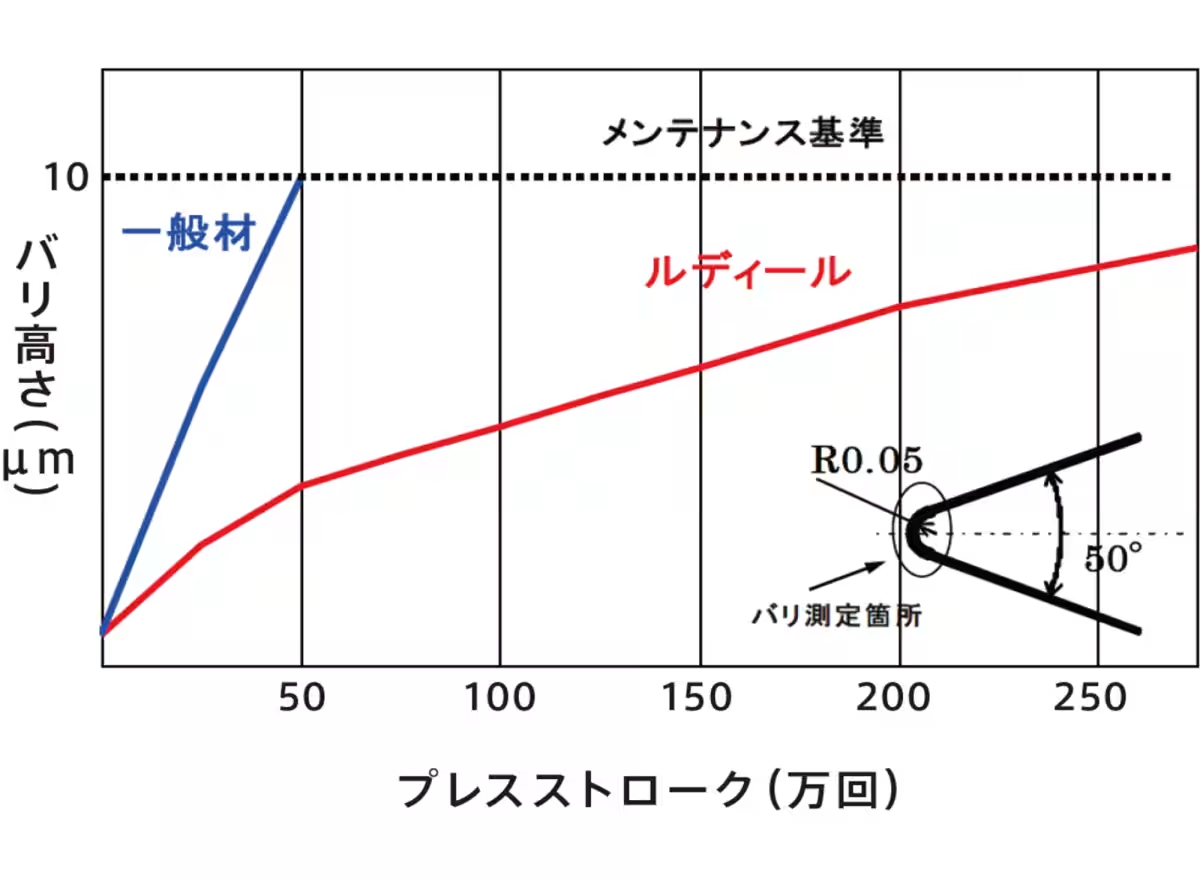

1. Reduced Mold Wear: L・DieL® effectively lowers wear rates on molds, promising increased durability and reliability in manufacturing processes.

2. Compatibility with Various Stainless Steels: It works seamlessly with most stainless steel finishes, including SUS304 and SUS430, making it versatile for different manufacturing needs.

3. Standard Compliant: The chemical composition and mechanical properties adhere to JIS standards, ensuring quality and consistency.

4. Preserved Aesthetics and Corrosion Resistance: Despite the modifications, the appearance and corrosion resistance typical of stainless steel remain unchanged.

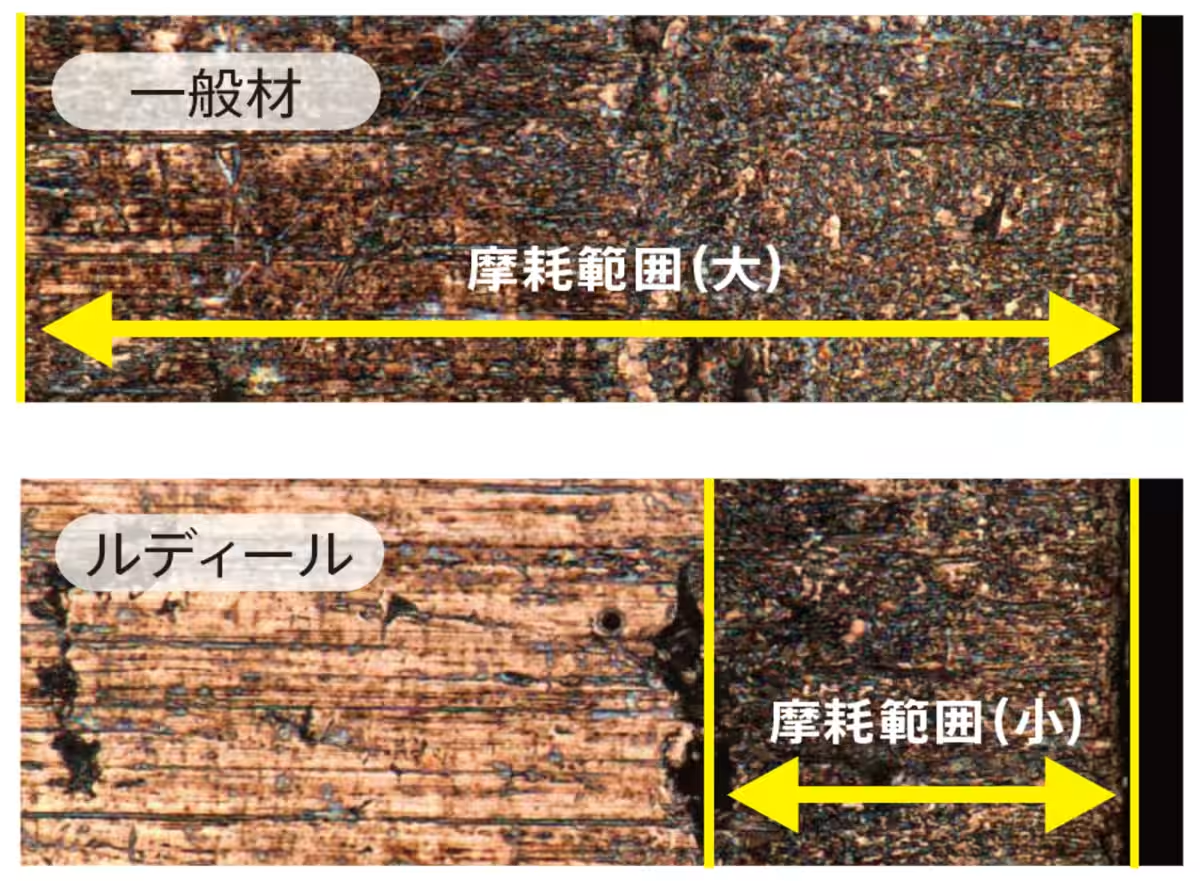

Wear Reduction Effect

Consider this example of wear reduction; with the base material being SUS304, at a clearance of 5μm and an operation speed of 600 strokes per minute, the difference in wear area between L・DieL® and standard materials demonstrates the significant impact this treatment has on mold longevity.

Structural Insights of L・DieL®

L・DieL® utilizes proprietary surface treatment techniques to soften the oxide film, thus reducing mold wear. Less frequency of maintenance is another benefit. The material is available in various configurations:

- - Steel types: SUS304, SUS430, etc.

- - Finishes: Spring, BA

- - Thicknesses: ranging from 0.08 to 0.50 mm

- - Widths: up to 600 mm.

For more details on the L・DieL® product, visit the product introduction page here.

Overview of Steel Products

Nihon Kinzoku's state-of-the-art equipment and specialized techniques have positioned the company as a leader within the industry. The innovative approaches to cold-rolled steel and other materials promise to meet various customer demands effectively.

You can learn more about our steel product range here.

Vision for the Future: NIPPON KINZOKU 2030

Aligned with its 11th management plan, titled 'NIPPON KINZOKU 2030', Nihon Kinzoku aims to become a Multi & Hybrid Material company that contributes positively to both people and the planet. The focus is on creating sustainable, diverse materials that fulfill performance requirements while fostering innovative product development that adapts to evolving market needs.

By centering on terms such as 'Multi & Hybrid Material,' 'Near Net Shape,' and 'Near Net Performance,' Nihon Kinzoku is committed to transforming its business structure through advanced technology, ensuring it stays relevant and responsive to customer needs.

For inquiries related to this release, please contact Nihon Kinzoku's General Affairs Department at 03-5765-8100 or visit their website for more information here.

For product and technical information, reach out to the Production Process Support Department at 03-5765-8113 or click here.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.