Revolutionizing the Food Industry: ECOSAS Oil Filtration Solution Achieves Cost Cuts and Zero Accidents

The Game-Changing ECOSAS Oil Filtration Machine

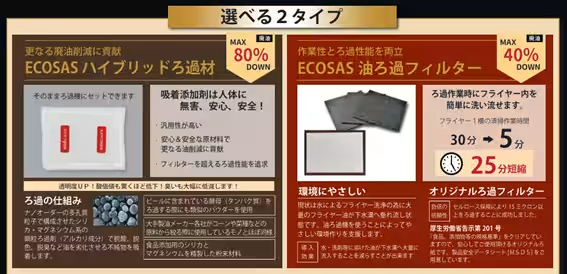

The food industry is currently facing a trio of significant challenges: skyrocketing raw material prices, a severe labor shortage, and increasing demands for Environmental, Social, and Governance (ESG) compliance. Amid these pressing issues, ASPiA JAPAN Co., Ltd. has introduced the ECOSAS Oil Filtration Machine, an innovative solution that simultaneously addresses these challenges while promoting cost efficiency and safety. With over 4,500 units installed, it has quickly become vital for food enterprises of all sizes, from major restaurant chains to small food manufacturers.

Addressing Industry Woes

The Weighing Factors:

- - Surging Vegetable Oil Prices: In the past two years, prices have surged by 40%, substantially exacerbating cost pressures.

- - Labor Shortages: The industry is grappling with a reduction in workforce, leading to increased risks of accidents during hazardous tasks.

- - ESG Expectations: With Japan's government aiming for substantial reductions by 2030, companies are pressured to adopt decarbonization practices and transparency.

- - Automated Needs: Big chains demand efficient operations, intensifying the need for automation.

The ECOSAS Oil Filtration Machine promises to tackle all these issues with its cutting-edge technology.

The Cost Savings in Numbers

Example Implementation: Company A

Company A, a supermarket chain specializing in ready-to-eat meals, experienced significant reductions in its oil usage:

- - Before Implementation: Used 43 cans of oil monthly.

- - After Implementation: Reduced to 32 cans (a 25.6% decrease).

- -Annual Cost Savings: Approximately 673,200 JPY.

Additionally, it dramatically cuts labor costs by reducing cleaning time from 40 minutes to about 5 minutes, resulting in another 238,773 JPY saved annually in labor expenses. The machine also enhances material efficiency by reducing detergent usage, contributing another 69,600 JPY in annual savings. In total, users can anticipate an annual saving of 981,573 JPY.

Safety First: Zero Accidents Over a Decade

The ECOSAS machine is revolutionary for its completely non-contact design, which allows users to operate it remotely without needing to approach high-temperature oil (between 160-180°C). This innovation significantly minimizes workplace hazards:

- - Zero Accidents: There's been no report of workplace injuries since its launch 10 years ago.

- - Reduced Risks: The machine eliminates the dangers of burns and injuries involved in moving heavy oil containers.

Upholding Quality and Sustainability

The ECOSAS system boasts state-of-the-art filters that prolong oil life and maintain taste consistency while adhering to food safety standards. Furthermore, it is dedicated to sustainability, as ongoing tests suggest that used filters can be entirely recycled, promising a reduction of 20-50 tons of CO₂ emissions annually.

Recognitions and Future Aspirations

The ECOSAS Oil Filtration Machine recently received the Restaurant Industry Contribution Award (2023), supported by Japan's Ministry of Agriculture, Forestry, and Fisheries, and the Ministry of Economy, Trade, and Industry. ISO9001 certification ensures its manufacture adheres to the highest quality standards.

CEO Statement:

"We designed the ECOSAS Oil Filtration Machine not just as a tool but as a strategic asset for oil management that emphasizes safety, quality, environmental consideration, and undeniable cost reduction. Our clients consistently express that there's no reason not to adopt this technology." - Nobuhisa Sasahara, CEO of ASPiA JAPAN.

The continuous expansion across various sectors—ranging from restaurant chains, supermarkets, and bento factories to hospitals—demonstrates the unwavering demand for the ECOSAS system. As the industry navigates the critical environment of rising costs and compliance pressures, the installment of ECOSAS units is expected to surge exponentially, reinforcing better practices within the food industry.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.