Introduction of Toyota Production System Training Tool by Jooto

Introduction of Toyota's New Training Tool

In an exciting development for efficiency and productivity within the auto industry, Toyota Motor Corporation has partnered with Jooto, a task and project management tool, to develop an innovative training tool called 'Standard Box.' This tool is designed to enhance operations based on the principles of the Toyota Production System (TPS).

Background

The Toyota Production System is renowned for its focus on eliminating waste while providing customers with high-quality products in a timely manner. This philosophy is ingrained in the core of Toyota's managerial practices and is a vital aspect that drives continuous improvement across all departments, from planning and design to production and sales, including indirect department operations like human resources and accounting.

With this new development, Jooto aims to aid in the standardization and improvement of work processes at Toyota. The project commenced in August 2023, with the tool expected to be implemented in the TPS Dojo's training program for office and technical employees starting January 2026.

Development Phases

The project's development is divided into several stages:

1. 2023: Conceptualization and requirement definition, leading to the initial design of the 'Standard Box,' which reflects TPS's insights on effective operations.

2. 2024: Prototype development and trial runs within specific departments, allowing for user feedback and UI improvements.

3. 2025: A full rollout is anticipated, with over 900 Toyota employees already engaging with the tool.

4. 2026 and beyond: Expansion of internal use to enhance productivity and operational quality across various functional areas.

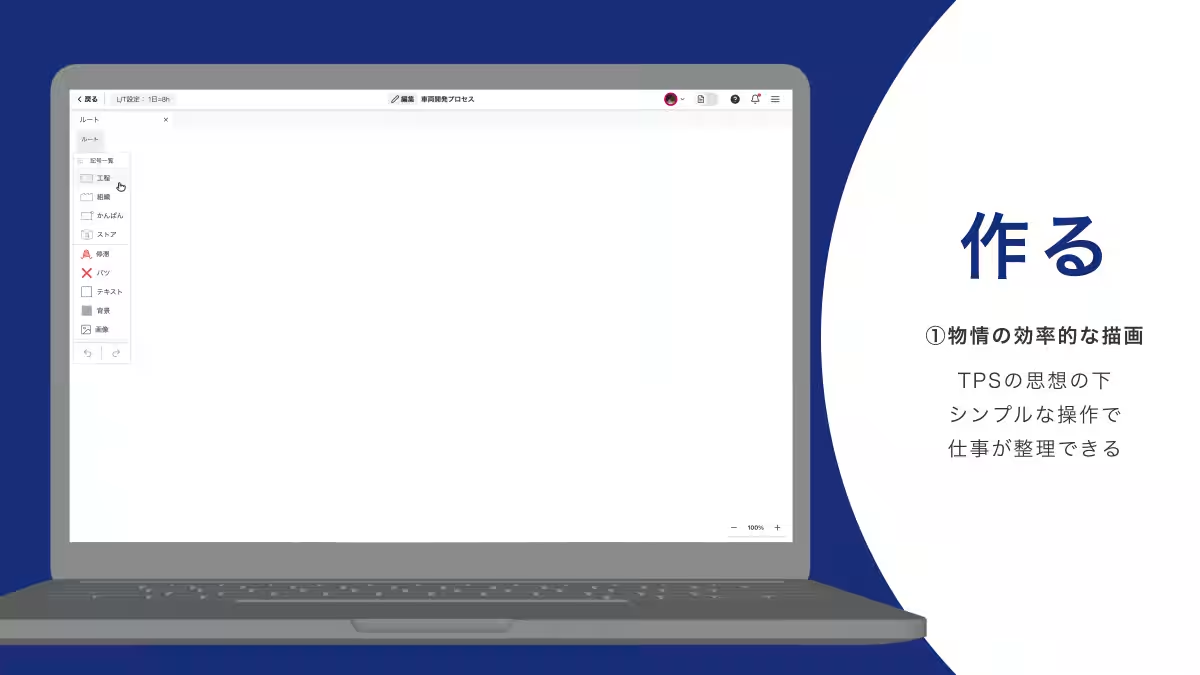

Features of the Tool

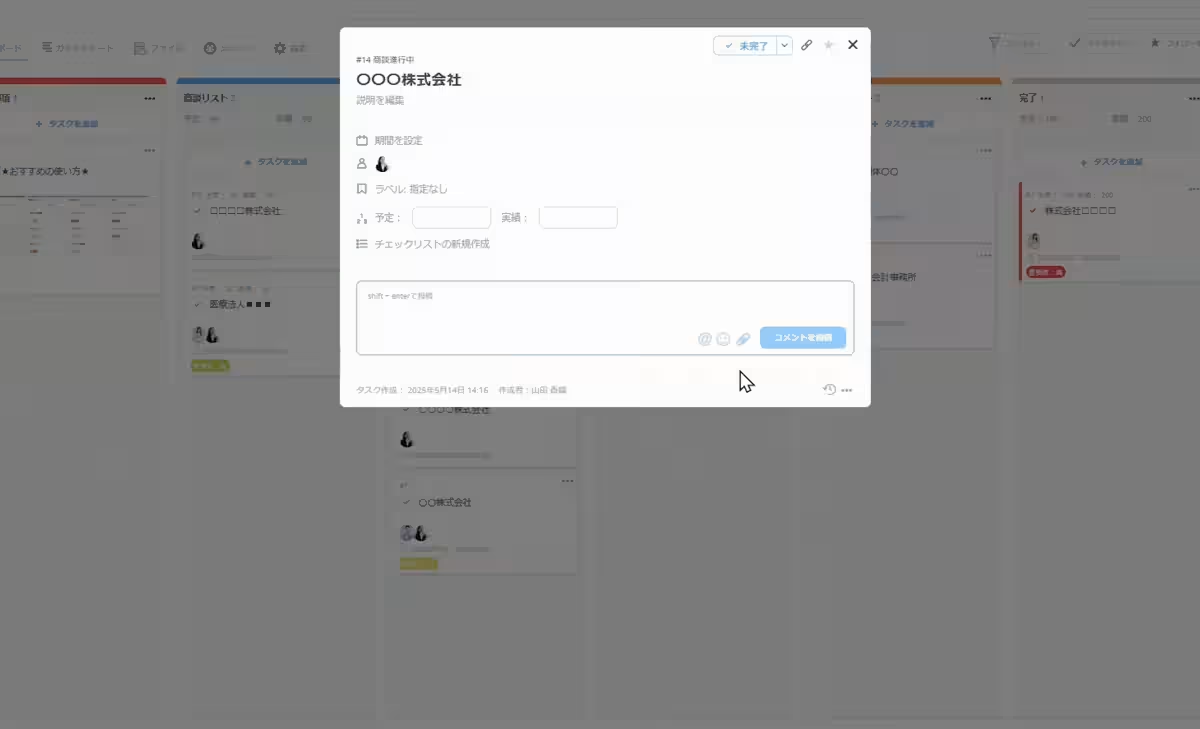

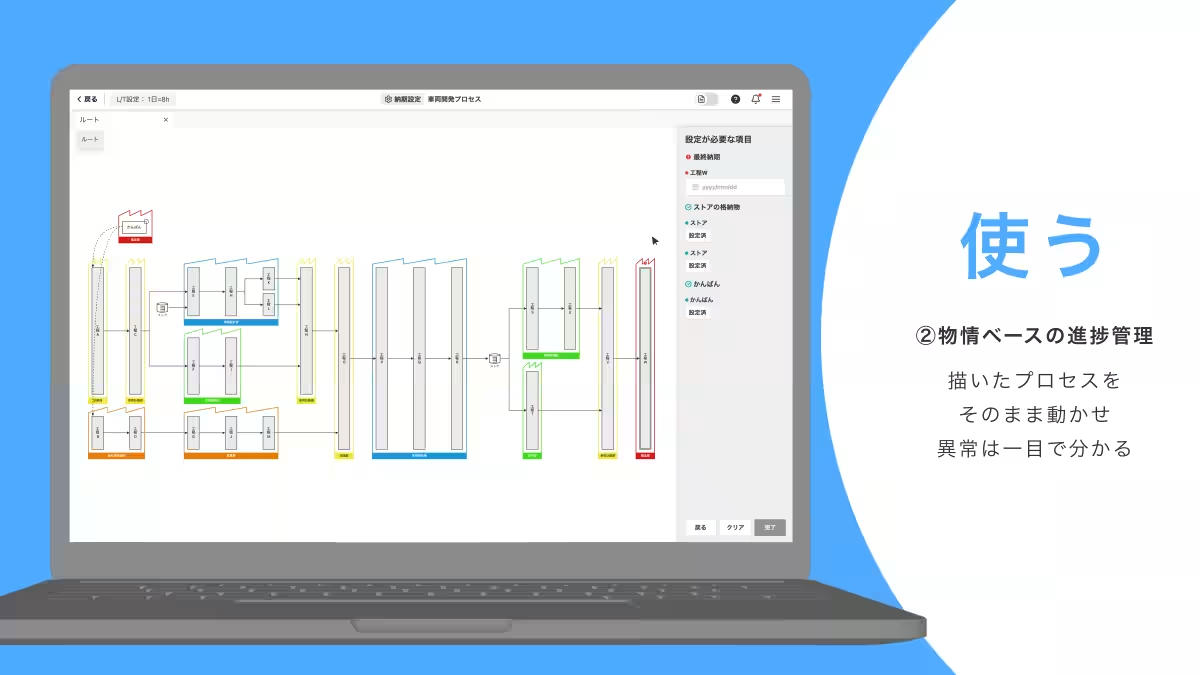

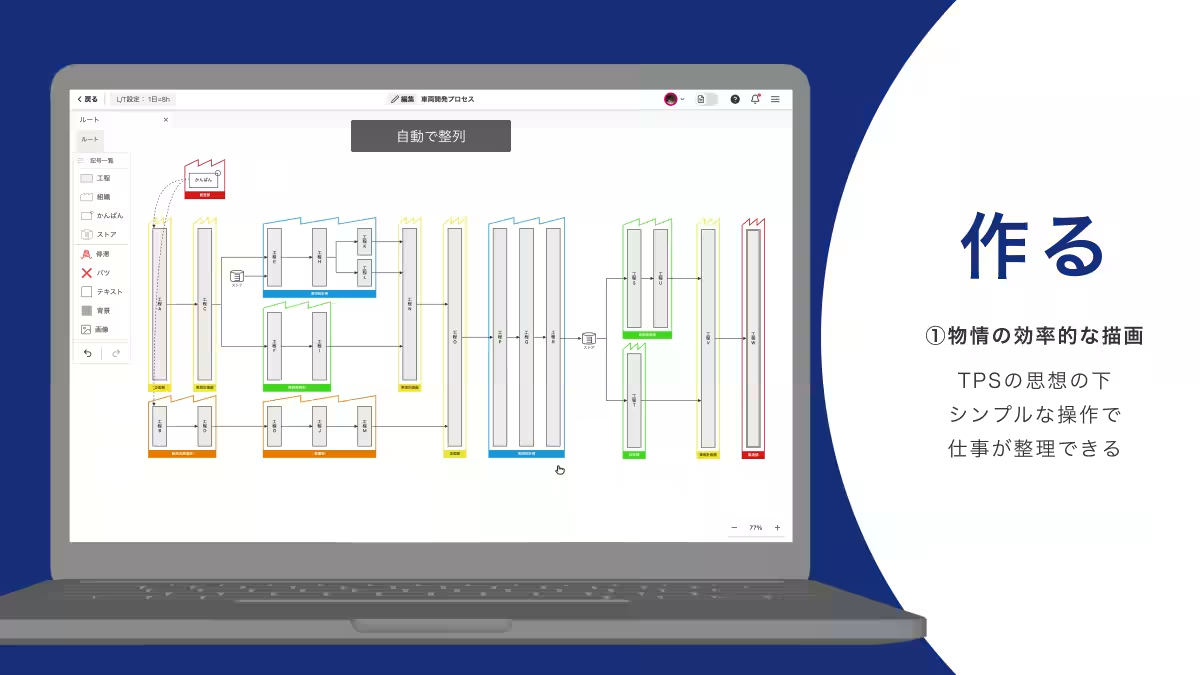

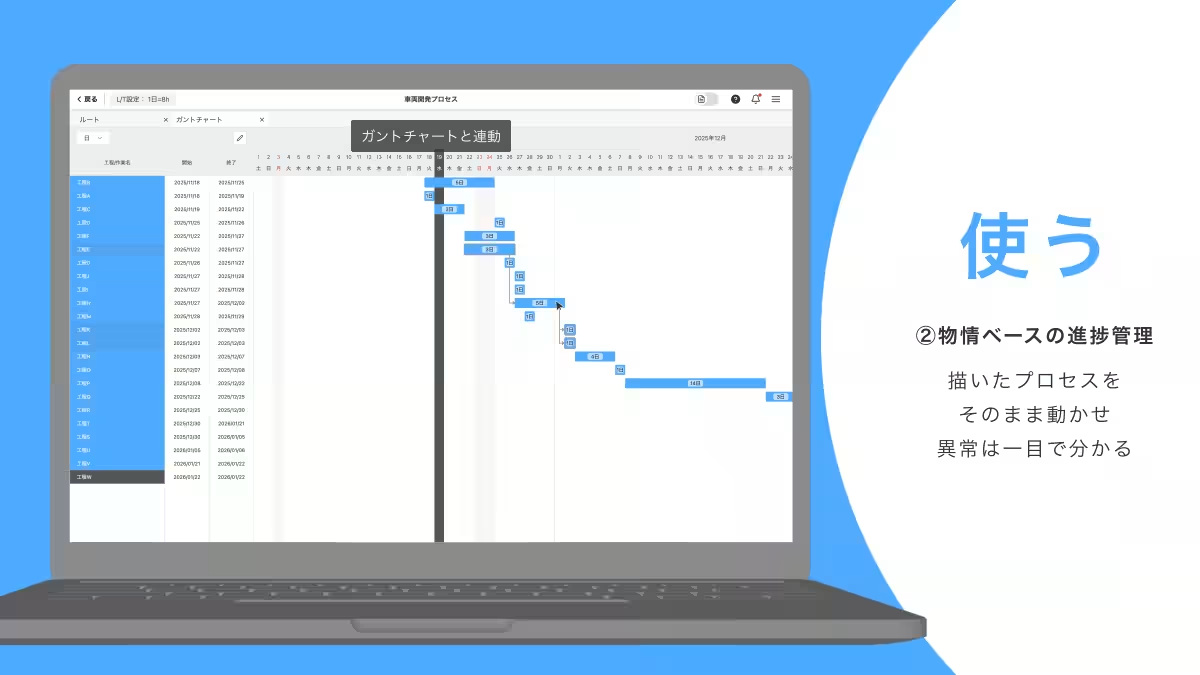

The 'Standard Box' is engineered to visualize and share standard processes while managing daily operations seamlessly. Potential benefits include:

- - Easy creation of '物と情報の流れ図 (Information and Material Flow Diagrams)' to support enhancement activities.

- - A comprehensive management approach to oversee progress, outcomes, and records of anomalies, streamlining reporting duties.

User Feedback

Initial impressions from Toyota employees indicate positive enthusiasm:

- - Developers appreciate the usability that allows for effortless diagram creation.

- - Quality assurance teams commend the tool’s convenience and alignment with TPS philosophies.

- - Participants note that the tool enhances their quality of productivity in improvement activities.

Future Prospects

Jooto's commitment goes beyond merely providing a new tool; it seeks to transform organizational productivity using digital solutions. By 2025, the aim is to create an environment where this tool is integral across all Toyota operations.

Jooto, which already serves over 400,000 users including over 2,500 corporate entities, plans to expand the reach of the 'Standard Box' tool not only within Toyota but also to external industries by aiding in work standardization.

Conclusion

The collaboration between Toyota and Jooto symbolizes a forward-thinking approach towards integrating digital technology with traditional production philosophies. As both companies strive for excellence, the 'Standard Box' marks a significant step in enhancing organizational capability and advancing operations more effectively.

In a nutshell, the introduction of the 'Standard Box' aligns perfectly with the ever-evolving landscape of business practices, bolstering efficiency and enabling Toyota to continue setting benchmarks in the automotive industry.

Topics Business Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.