Revolutionizing Tube and Wire Manufacturing with Hexagon's Latest TubeInspect System

Hexagon Unveils the Revolutionary TubeInspect System

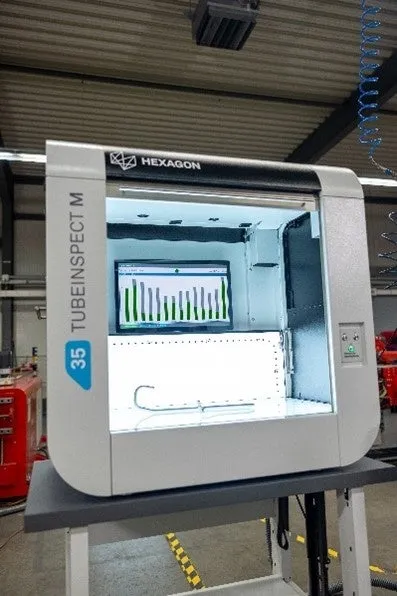

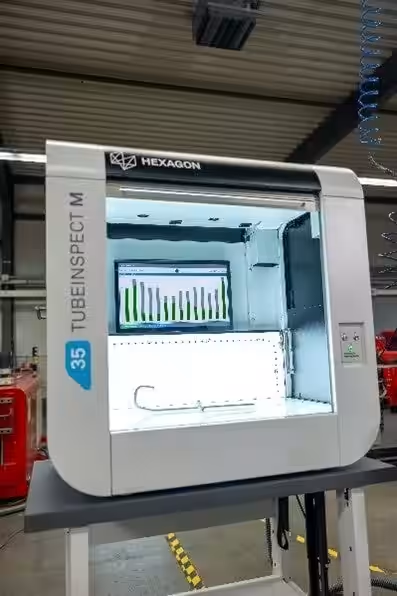

On March 28, 2025, Hexagon's Manufacturing Intelligence division, located in Chiyoda, Tokyo, announced the launch of its latest non-contact optical quality inspection solution, the TubeInspect system. This state-of-the-art system offers high-precision measurement results in just seconds, thereby streamlining the workflow of tube and wire production and significantly enhancing manufacturers' productivity and return on investment (ROI). Built on advanced measurement tools and software technology, the TubeInspect system integrates sophisticated optical measurement with seamless automation, leading to substantial improvements in operational efficiency.

Key Features of the 2025 TubeInspect System

The 2025 TubeInspect measurement cell stands out by delivering immediate optical measurements and ensuring smooth workflow integration with all leading CNC bending machines. In a highly competitive manufacturing landscape, particularly in sectors such as e-mobility, the increasing complexity and customization of parts create challenges in maintaining profit margins. Traditional inspection methods often become bottlenecks in the production process, leading to decreased production speed, quality inconsistencies, and waste. To address these issues, the TubeInspect system offers several groundbreaking features:

- - High-Speed Optical Measurement: The system provides precise non-contact evaluations, delivering high-accuracy measurement results within seconds while ensuring compliance with stringent tolerance specifications. Enhanced temperature compensation and ISO 17025 certified calibration maintain stable accuracy even in unfavorable conditions such as oil contamination, dust, or high temperatures.

- - Seamless Integration with BendingStudio XT Software: The integration with Hexagon's BendingStudio XT software creates a closed-loop manufacturing process, allowing real-time correction data to be sent directly via an interface compatible with over 45 leading bending machine manufacturers. This functionality enables the creation of perfect components within just 1 to 3 automatic correction loops, enhancing consistency while reducing waste.

- - Automated Workflows that Reduce Inspection Time: The system features one-click operations, automatic measurement of drill holes, a user-friendly on-device Human-Machine Interface (HMI) displaying concise measurement results, and remote asset monitoring. These capabilities minimize manual intervention, improving overall productivity across production lines.

- - Easy and Flexible Implementation Process: Designed with usability in mind, the workflow allows operators to easily adapt without significant production interruptions, enhancing manufacturing efficiency in a short timeframe. The rapid automated setup process enables the measurement cell to become operational within minutes, and the ability to handle multiple component types within a single workflow eliminates the need for expensive mechanical gauges, significantly reducing quality inspection time.

The latest TubeInspect measurement cell, alongside BendingStudio XT software, offers a turnkey transformation for tube and wire manufacturing processes, leading to swift ROI. This revolutionary system reinvents quality control for tubes and wires, applicable across various industries from automotive exhaust and brake line inspections to quality management of safety-critical aerospace and energy plant components. Particularly for the production of components in electric and hybrid vehicles, such as motor hairpins and busbars, this solution helps maintain precision manufacturing standards while enhancing competitiveness.

Dr. Christoph Dold, Senior Product Manager at Hexagon, shares insights on the system's capabilities: "The 2025 TubeInspect measurement cell dramatically improves the speed and accuracy of tube and wire production processes in any manufacturing environment. Our strengthened integration with BendingStudio XT software allows us to achieve perfect components through just a few correction loops, ensuring the highest quality and productivity. We have already seen ROI improvements from clients who have implemented this system, presenting a transformative potential for companies reliant on manual processes or conventional quality inspection techniques."

The fully integrated 2025 TubeInspect measurement cell with BendingStudio XT is currently available for order through Hexagon's global sales network. For more information on how this innovative solution can transform your manufacturing operations, please visit the Hexagon website.

About Hexagon

Hexagon is a global leader in precision technology across various scales. Our digital twin, robotics, and AI solutions are revolutionizing industries that support real-world applications. Our technology facilitates the creation of production ecosystems and human-centric ecosystems, promoting connectivity and autonomy, all aimed at building a sustainable and prosperous future. The Hexagon Manufacturing Intelligence division leverages data-driven solutions from design, engineering, manufacturing, to measurement to empower smarter product manufacturing. With approximately 24,500 employees across 50 countries, Hexagon (Nasdaq Stockholm: HEXA B) recorded a net revenue of approximately 5.4 billion euros. For more details, visit hexagon.com.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.