Topre Introduces MISUMI floow to Improve Efficiency in Gifu Plant Operations

Enhancement of Operations at Topre's Gifu Plant with MISUMI floow

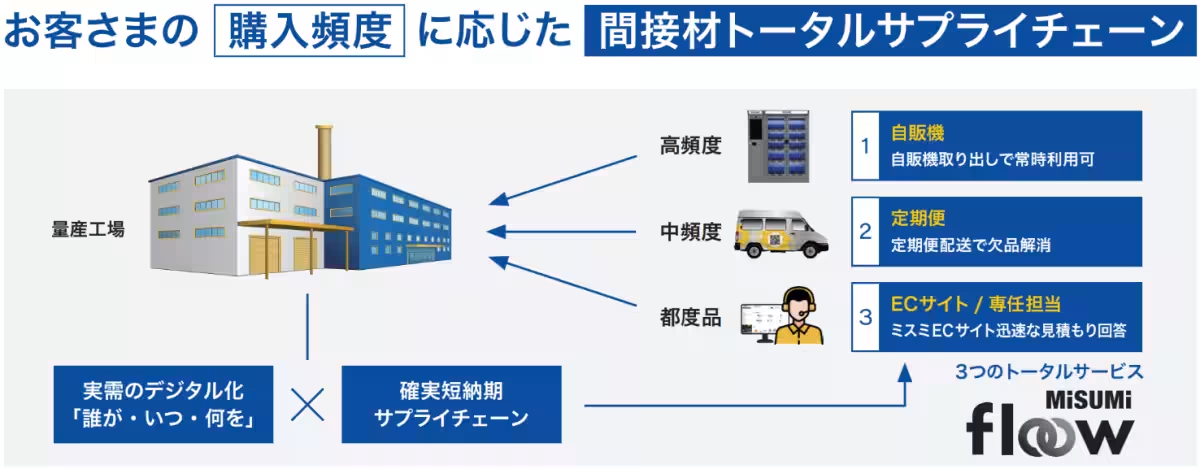

Topre Corporation, known for its production of automotive press parts and air conditioning equipment, has recently adopted the MISUMI floow system at its Gifu plant. This innovative solution, developed by MISUMI Group, aims to significantly reduce the total indirect material costs and enhance inventory management through automation and real-time data visualization.

Overview of Topre Corporation

Topre Corporation, headquartered in Chiyoda, Tokyo, specializes in manufacturing and selling a wide range of products, including automotive parts, temperature-controlled logistics items, keyboards, and air conditioning units. The Gifu facility plays a crucial role in the production of air conditioning equipment; however, it faced significant challenges in managing various consumables such as cloth tape and cut-resistant gloves. The reliance on manual operations led to frequent stock shortages, overstocking issues, and urgent procurement requests, which created both quality assurance risks and psychological burdens for the staff.

To address these inefficiencies, Topre introduced the MISUMI floow system, aimed at automating inventory management and procurement processes. This implementation created an environment where essential items could be easily accessed via a vending machine, thereby eliminating the burdens associated with manual inventory management. It has streamlined ordering, inventory tracking, and usage history visibility while ensuring user accountability through facial recognition.

Benefits of Implementing MISUMI floow at Topre

The introduction of the MISUMI floow system has transformed the procurement and management tasks that previously consumed significant time and effort. Prior to implementation, managers had to frequently deal with labor-intensive tasks such as manually tracking orders, conducting stock checks, and responding to requests for materials. On some days, ordering could occur more than five times, placing a heavy burden on the management team.

Since introducing MISUMI floow, the automated vending machine system has drastically reduced the need for stock counts and order placements. The innovative design of the vending machine, which illuminates its dispensing slot when a needed item is selected, has further alleviated the burdens associated with finding and conducting transactions for necessary materials. Consequently, significant time savings have been achieved, allowing personnel to focus on their primary operational tasks.

Additionally, the psychological burdens associated with urgent procurement and quality assurance risks have decreased. The system automatically updates stock levels in real-time, reducing the need for verification or aggregation of data, which streamlines processes and frees up valuable time resources.

Enhanced Security and Data Transparency

The MISUMI floow system not only automates inventory management but also significantly enhances security with its facial recognition technology. This allows for real-time visibility into order processing, inventory management, and individual usage tracking, ensuring transparency and enabling early detection of anomalies in stock levels. This increased visibility has led to improved shelf management and expanded item categories, tailoring operations effectively to the needs of the facility.

Testimonials from Topre Staff

Mr. Yoshinori Sahashi, Production Manager at the Gifu plant, expressed, "The reliability of MISUMI floow as a system made it easy to explain its benefits to our company. During a visit by our president to the Gifu facility, he remarked on how impressive the vending machines were, highlighting a shared understanding between the management and the team about the system's effectiveness. We aim to expand the types of consumables managed through this system to further reduce manual workloads."

Mr. Takeyuki Sugiyama, an assistant manager at the Gifu plant, noted, "The key deciding factor was how MISUMI floow effectively reduces the workload for managers. The transition from a manual ordering system to an automated one is incredibly valuable. Looking ahead, analyzing use history data will help eliminate gaps in stock and consumption, allowing for rapid identification of anomalies. Ultimately, we envision a future where managing consumables via vending machines becomes the norm, enabling teams to focus solely on their core activities."

Conclusion

The successful integration of MISUMI floow into Topre Corporation's operations exemplifies the potential for digital innovation to optimize manufacturing processes. By transitioning to automated inventory management, Topre demonstrates a commitment to enhancing operational efficiency, alleviating employee burdens, and fostering an environment where teams can focus on delivering high-quality products. With the advantages of this system, Topre is paving the way for a more efficient and responsive manufacturing environment, setting a standard for other companies to follow.

Learn more about MISUMI floow and its benefits on the official MISUMI website.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.