Koike Construction Implements DX Through Innovative Robotic Experiment for Increased Efficiency

Koike Gumi's Robotic Innovations in Construction

In an age where the construction industry faces critical challenges such as an aging workforce and a significant labor shortage, Koike Gumi has taken a significant step forward. On August 29, 2025, the company conducted a public experiment at its Tsukuba Technology Center in Ibaraki Prefecture, unveiling two groundbreaking technologies: the Sleeve Inspection System, "SleeveRing," and the Survey Robot, "Staffy."

Background of the Initiatives

With the increasing scarcity of skilled labor, traditional construction tasks like sleeve inspections and surveying have become cumbersome, often requiring multiple workers and extensive time commitment. Understanding the need for increased efficiency and automation, Koike Gumi collaborated with Japan Computer System Co. and KenRobotech to develop technological solutions aimed at transforming these processes.

Sleeve Inspection System: SleeveRing

Understanding the Sleeve Testing Challenge

In reinforced concrete construction, sleeves are tubular openings made before concrete pouring to route pipes or wires. Historically, inspecting these sleeves entailed labor-intensive measurements by workers, often leading to time-consuming tasks that required verification against design blueprints. There could be hundreds of sleeves requiring inspection, making efficiency a paramount concern.

Innovative Features of SleeveRing

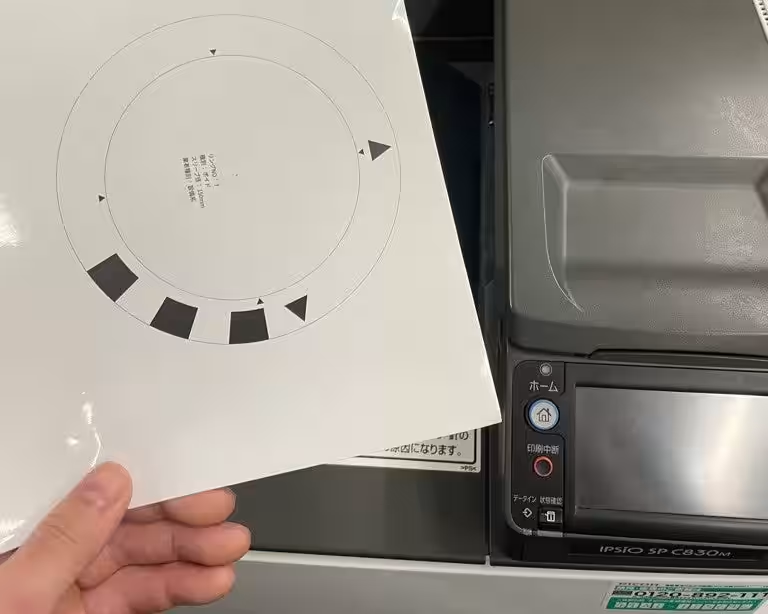

The SleeveRing system leverages cutting-edge AI and AR technologies to revolutionize the inspection process. Only a tablet with a dedicated app and easily printable AR markers are needed for operation, simplifying setup. The inspection unfolds in the following steps:

1. Print AR markers.

2. Attach AR markers to the sleeves.

3. Capture images of the setup using the tablet.

4. Allow the AI to recognize the sleeves and determine correctness through image recognition.

As an additional feature, inspection results are shared in real-time via a web application, enabling remote monitoring and immediate decision-making.

Achieving Remarkable Time Savings

The deployment of SleeveRing has dramatically cut inspection times, allowing instantaneous verification of design consistency by overlaying design data on the AR interface.

Survey Robot: Staffy

Development Journey of Staffy

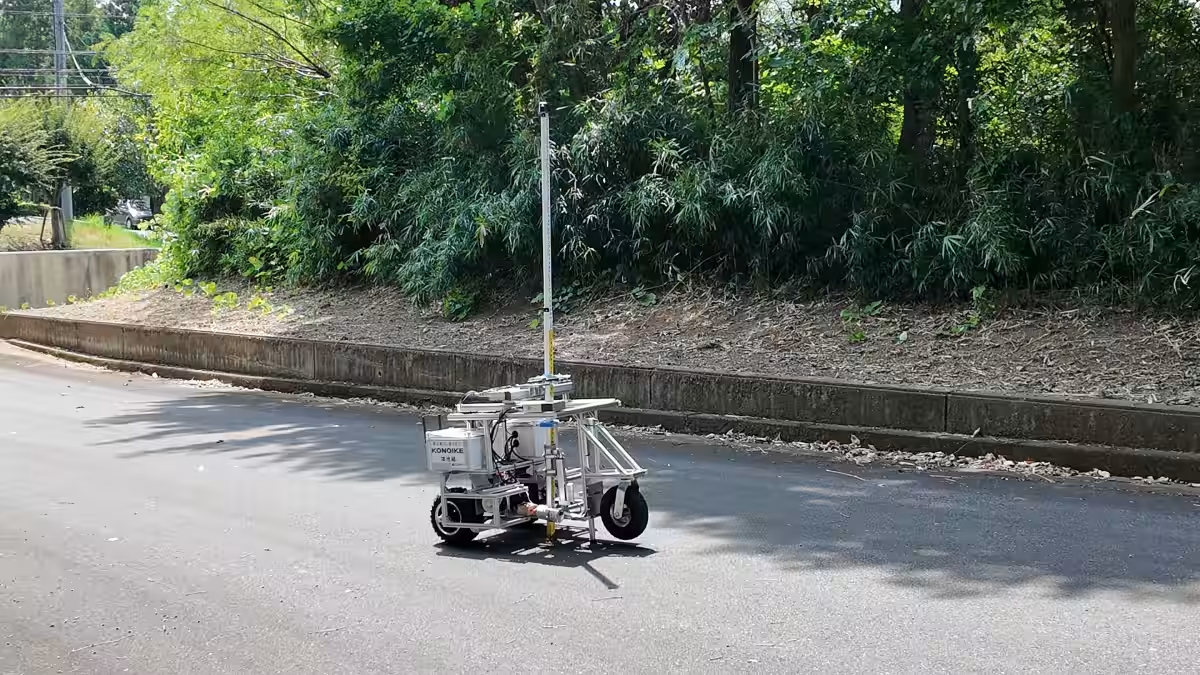

Traditional surveying tasks that necessitate two operators have escalated labor costs and time. Recognizing the need for a more efficient approach, Koike Gumi and KenRobotech joined forces to create Staffy, a robotic solution designed to automate surveying activities.

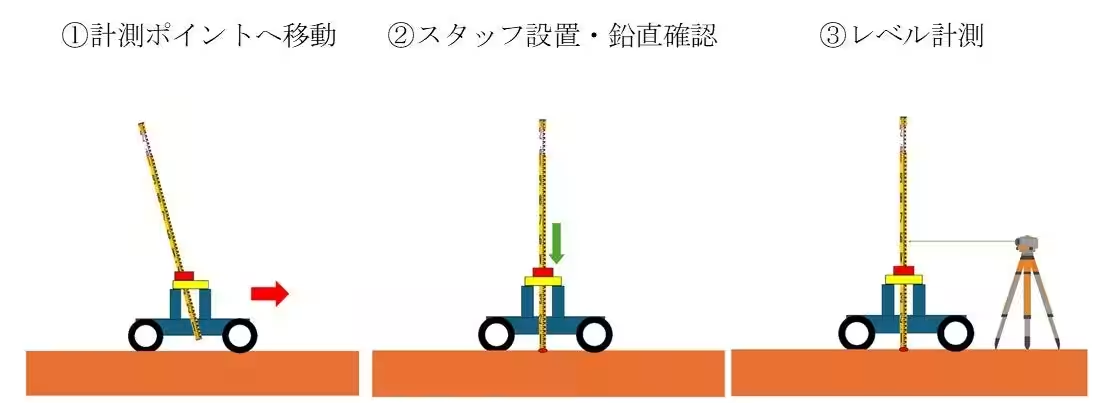

Key Features of Staffy

Equipped with a vertical support table for survey staffs, a rotation mechanism, a spray device, and mobile driving wheels, Staffy is a versatile addition to the construction process. Its remote operation capabilities, facilitated by an onboard camera system and a display controller, allow for seamless management.

Validation of Efficient Operation and Labor Reduction

The public experiment confirmed that Staffy could maintain vertical accuracy and appropriately align the scale face with the surveying equipment direction. Compared to the traditional two-person surveying process, Staffy enables operations with just one operator, thus significantly reducing manpower requirements.

Future Implications

Koike Gumi intends to further enhance the functionality of the showcased technologies and explore their application in other construction domains. By utilizing these advancements in digital transformation (DX) and information communication technology (ICT), the company aims to resolve persistent challenges in the construction industry effectively.

Summary of the Public Experiment

- - Date: August 29, 2025

- - Location: Koike Gumi Tsukuba Technology Center, Ibaraki Prefecture

- - Organized by: Koike Gumi, based in Osaka, Japan

- - Collaborators: Japan Computer System Co. and KenRobotech

The innovations presented by Koike Gumi signal a notable shift in the construction landscape, where robotics and advanced technology play an instrumental role in streamlining operations and overcoming industry hurdles.

Topics Other)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.