Bioworks Demonstrates Chemical Recycling of Used Socks into Polylactic Acid

Introduction

Bioworks Inc., a company based in Kyoto, has made significant strides in establishing a chemical recycling technology that converts used socks into polylactic acid (PLA). As part of the Tokyo Co-inNovators program, they conducted a pilot study to validate this innovative process. This article explores the background, methodology, and key findings from the experiment and participant surveys.

Background

The recycling rate for textiles globally is under 1%, which poses a significant challenge given that many clothing items are made from blended materials that complicate resource circulation. According to Japan's Ministry of the Environment, consumable items like socks and underwear are frequently purchased and discarded. A report by Bioworks indicates that only about 10% of these items are reused or recycled, highlighting a major environmental issue.

With approximately 66% of all clothing from households ending up in landfills, Bioworks identified socks as a primary target for their recycling efforts. Due to their short lifespan and lack of recycling opportunities, socks present a unique challenge in promoting a circular economy.

Pilot Study Overview

In collaboration with Tarrow Tokyo, socks made from PlaX—a next-generation synthetic fiber—were distributed for consumer use. Post-usage, the socks were collected for chemical recycling. The goal was to assess the feasibility of turning these post-consumer materials back into high-quality PLA.

Collection Methods

1. Direct Mailing: Consumers received collection bags made from PLA and were instructed to mail their used socks.

2. Physical Collection Points: Collection boxes were placed at Bioworks and partner companies for easy drop-off.

Sock Composition

The socks distributed contained a blend of materials: 58% cotton, 23% PLA, 11% nylon, 6% polyester, and 2% polyurethane.

Results of the Pilot Study

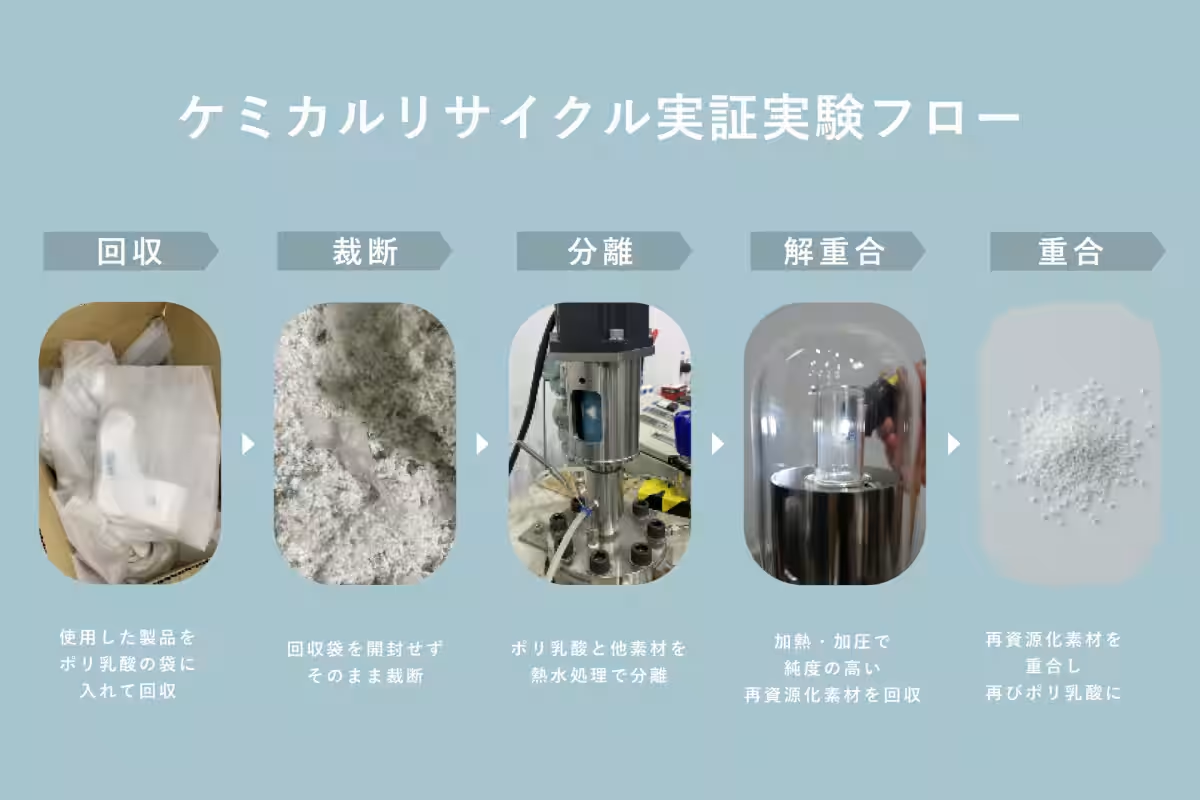

The objective was to verify whether even soiled socks could be transformed back into PLA through chemical recycling. The process was tested at both lab and pilot scales, confirming that high-purity, high-quality recycled materials could indeed be produced.

Laboratory results showed that the optimal conditions for recycling were effective, while pilot tests validated the quality of the resulting PLA. This new material performed comparably to traditional products, underscoring the viability of recycled PLA in the market.

However, challenges related to raw material yield during separation and economic aspects for commercialization were identified. Bioworks aims to address these by refining designs of high-blend products and expanding the distribution of PlaX.

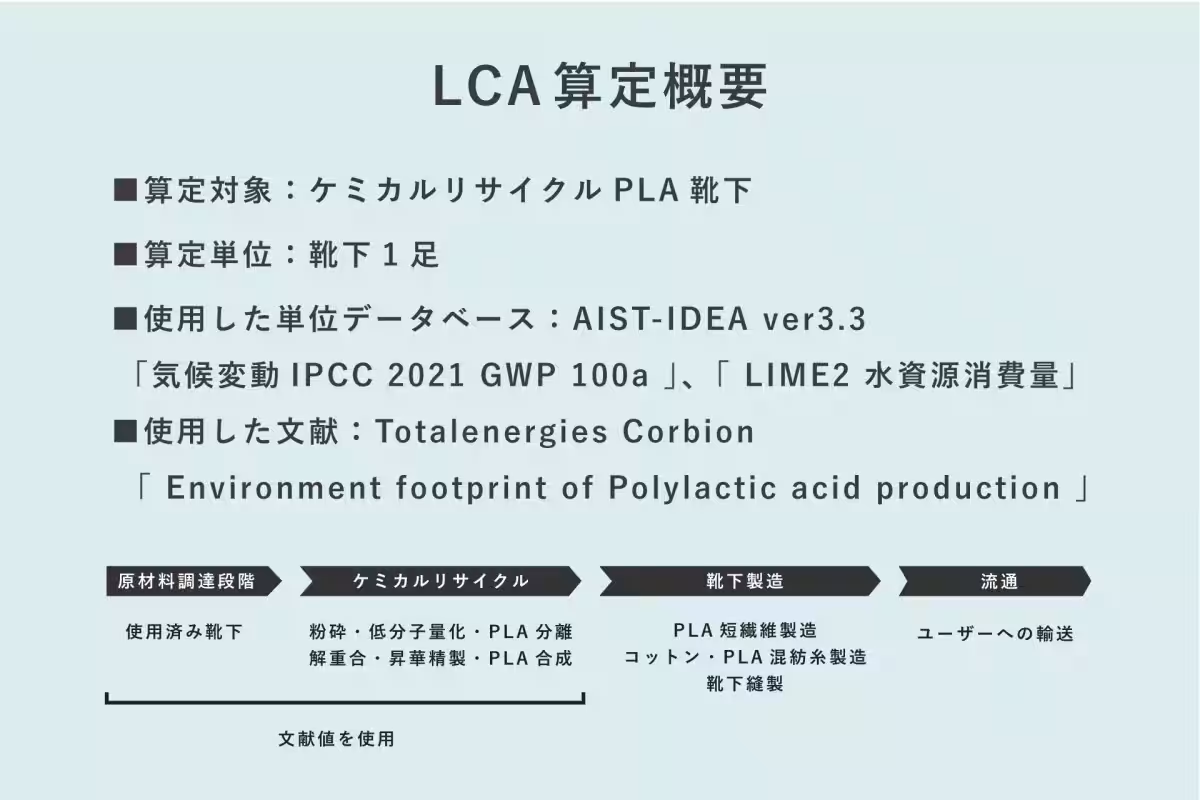

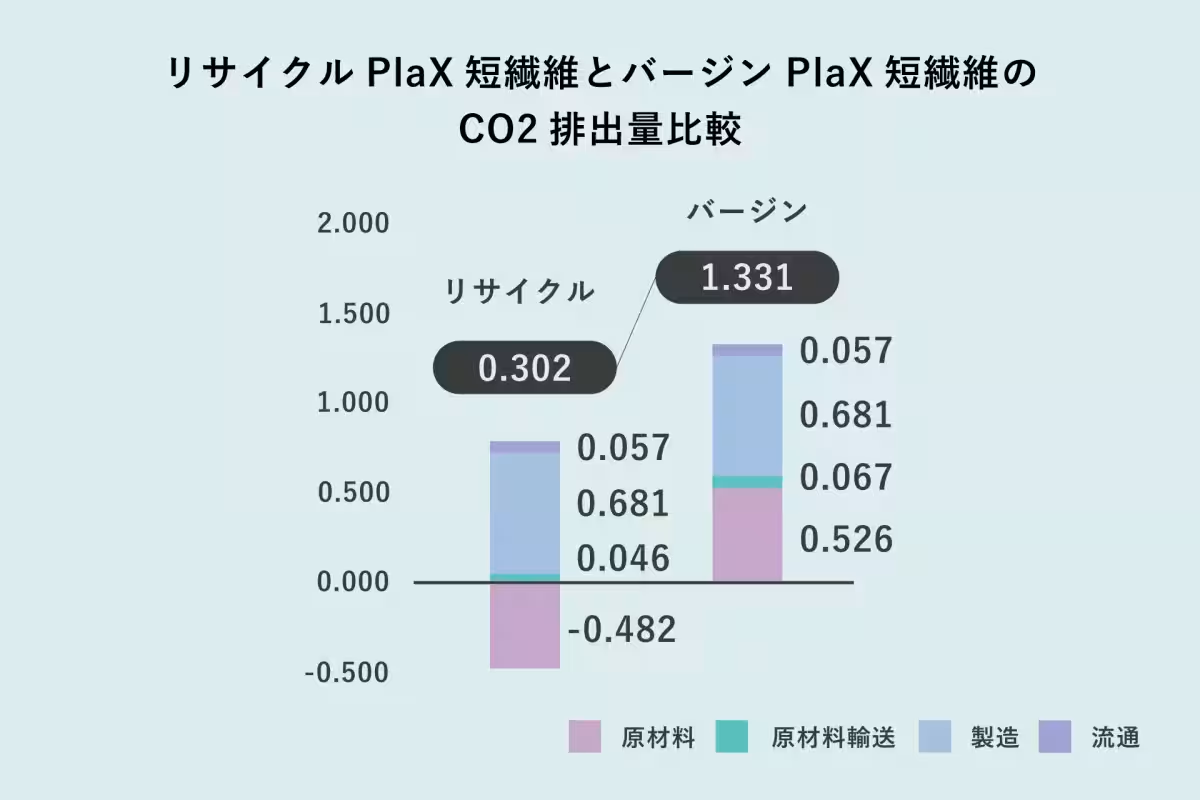

The life cycle assessment (LCA) suggested that using recycled materials for producing socks could lead to an estimated 9% reduction in CO2 emissions compared to traditional materials. Furthermore, recycled PlaX short fibers demonstrated an impressive 80% reduction in CO2 emissions during production compared to their conventional counterparts.

Consumer Feedback

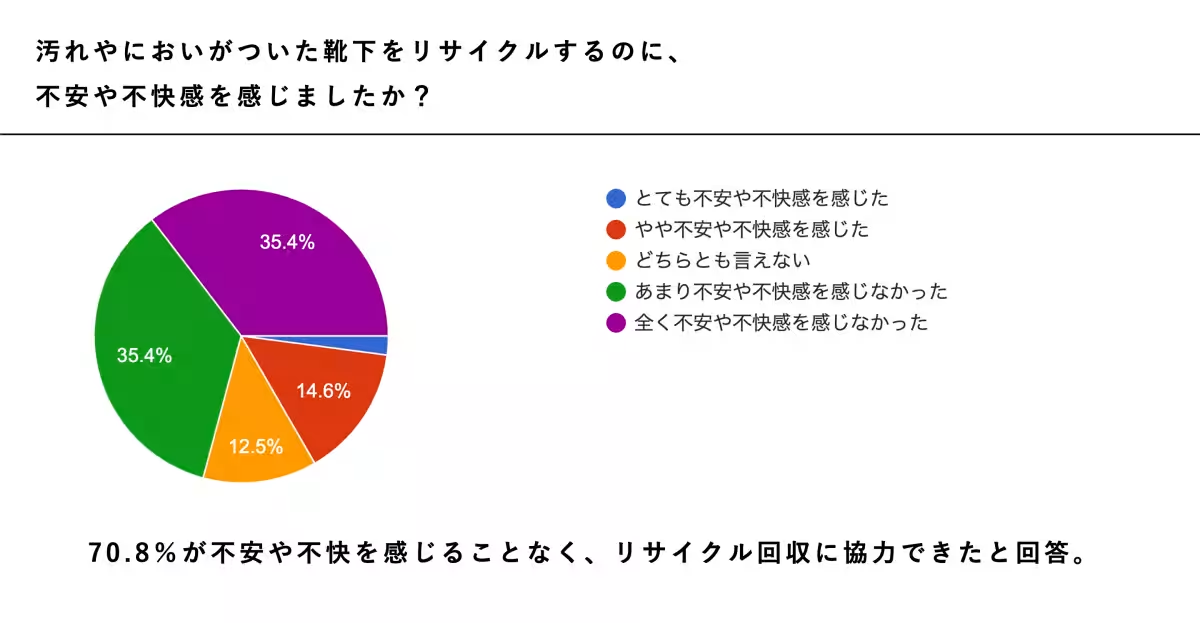

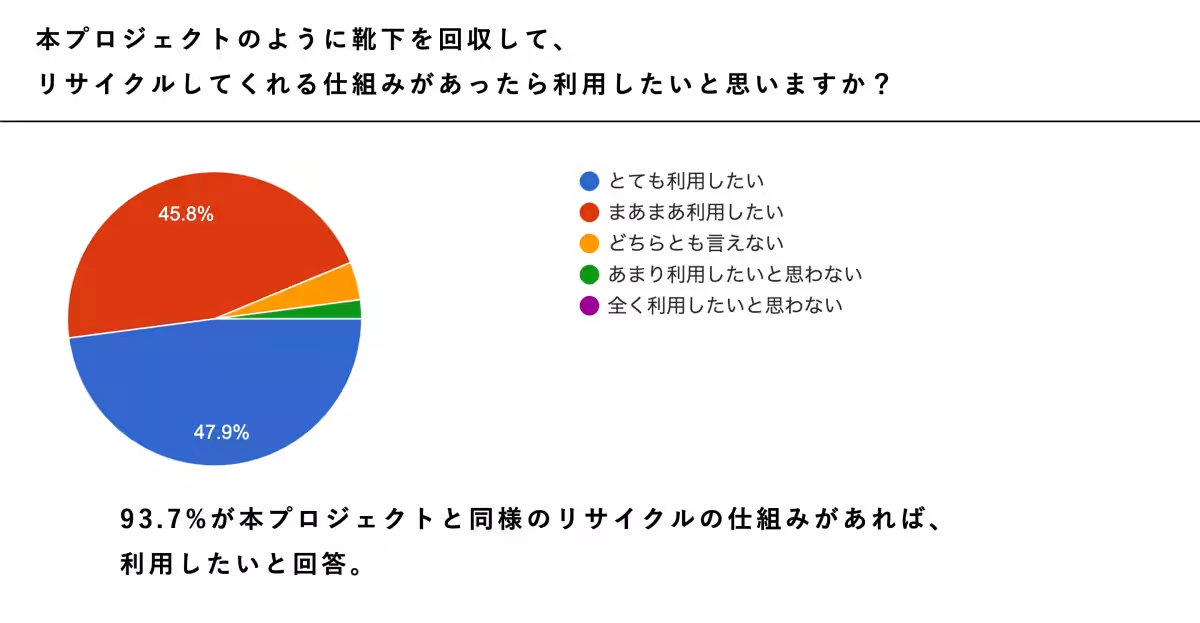

To gauge consumer sentiment regarding the recycling initiative, Bioworks conducted surveys after the collection phase. It was found that 70.8% of participants felt no discomfort or unease about recycling used socks, indicating a low psychological burden associated with the process. Additionally, 93.7% expressed interest in future recycling initiatives, highlighting a strong willingness to participate in sustainability efforts.

Many respondents were open to purchasing socks made from recycled materials if priced similarly or cheaper than regular products, suggesting market potential for recycled goods.

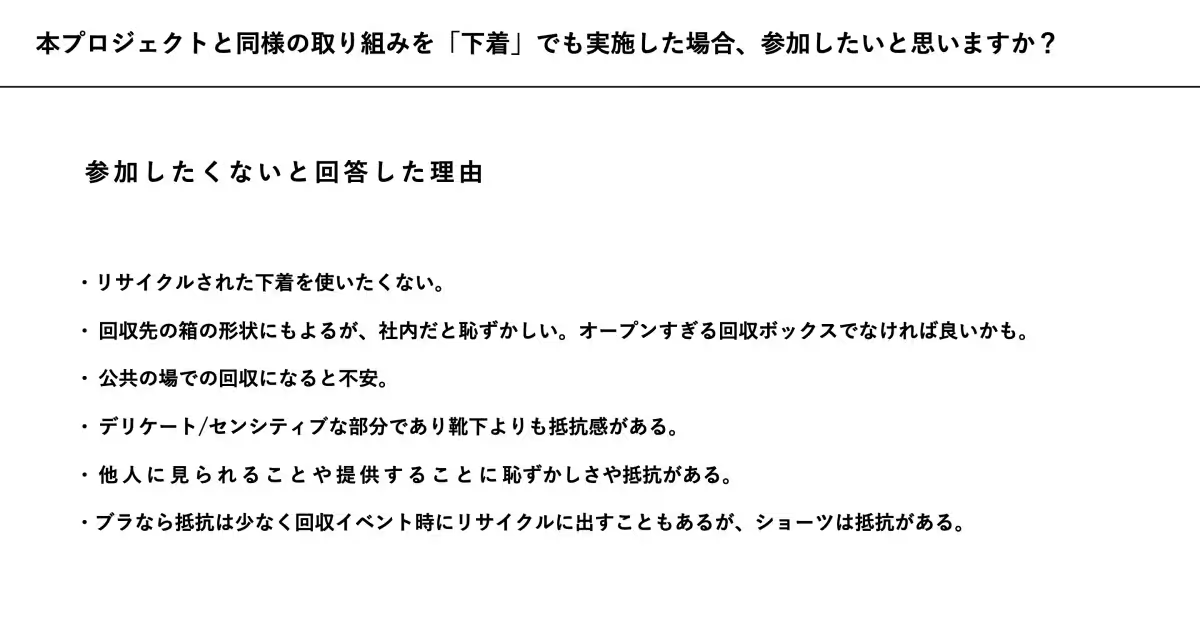

Conversely, when considering the recycling of more personal items like underwear, participant interest notably waned due to perceived psychological barriers, revealing the need for strategic communication and education surrounding such initiatives.

Conclusion

Bioworks is on the forefront of developing sustainable recycling solutions that pave the way for a circular fashion economy. Moving forward, they plan to build on the insights gained from this pilot study to establish robust recycling models that range from collection to reprocessing, in collaboration with partner companies. The success of this initiative emphasizes the importance of innovative thinking in addressing environmental challenges in the textile industry.

About PlaX

PlaX is an environmentally friendly material made using plant-based polylactic acid (PLA) and proprietary additives, contributing to reduced environmental impact and the potential for a circular economy in textile production.

Topics Consumer Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.