ExtraBold Unveils DirectFeed System: A Game Changer for Next-Gen 3D Printing

ExtraBold Revolutionizes 3D Printing with DirectFeed Feature

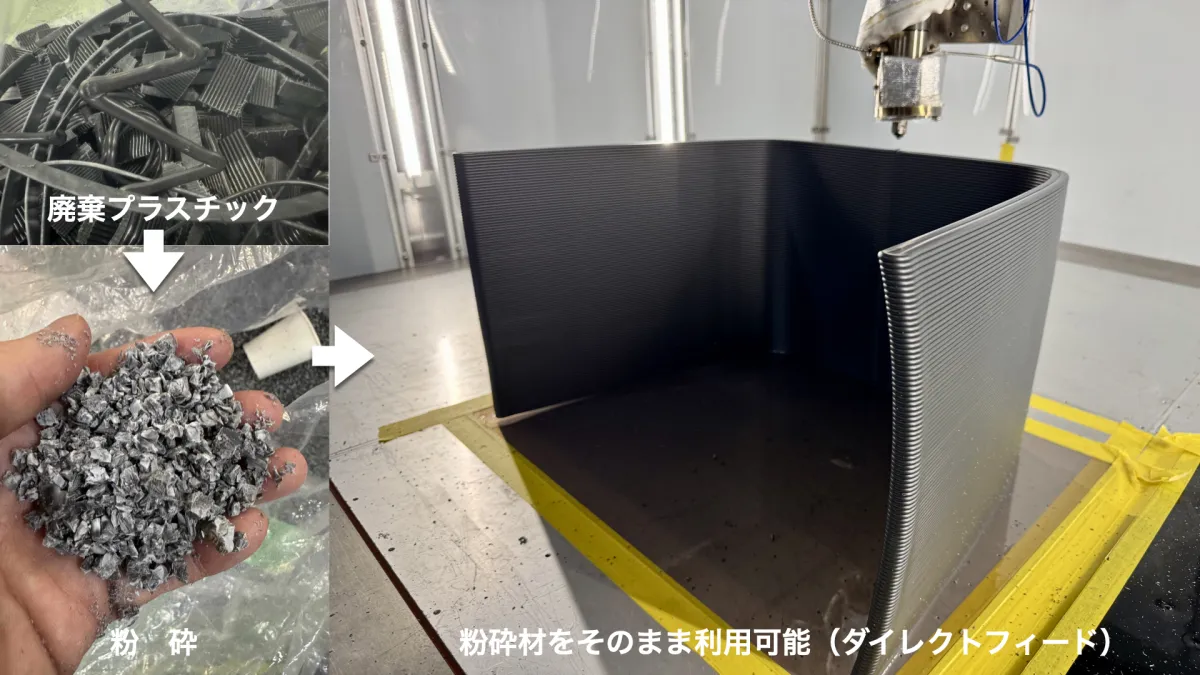

ExtraBold, a Tokyo-based startup led by CEO Yuji Hara, has recently announced an exciting new feature called the DirectFeed system for its large-scale 3D printer, the EXF-12, and the collaborative robot-type printer, the REX-BUTLER. Set to be released later this year, this innovative add-on allows for the direct use of powdered plastic waste in the 3D printing process, bypassing the need for the traditional pelletization step. This breakthrough could reshape how we view recycling and waste usage in additive manufacturing.

What is the DirectFeed System?

The DirectFeed system operates similarly to conventional MEX (Material Extrusion) 3D printers, utilizing thermoplastic resins. However, the standout feature of DirectFeed is its ability to directly feed ground plastic waste into the printing process, making it a significant shift from traditional methods. Users can simply input the powdered material without needing to undergo the costly and time-consuming pelletization process.

While there are some limitations—such as size constraints on the ground material and a requirement for the material to be of a single type—the benefits of DirectFeed are considerable.

Key Features of DirectFeed

- - Direct Feeding of Ground Plastic: By eliminating the pelletizing step, this system enhances cost-efficiency and expedites the 3D printing workflow.

- - Reduced Thermal History: Since reprocessing the plastic into pellets requires reheating, DirectFeed minimizes these heat-related issues, ultimately preserving the quality of recycled materials and improving print outcomes.

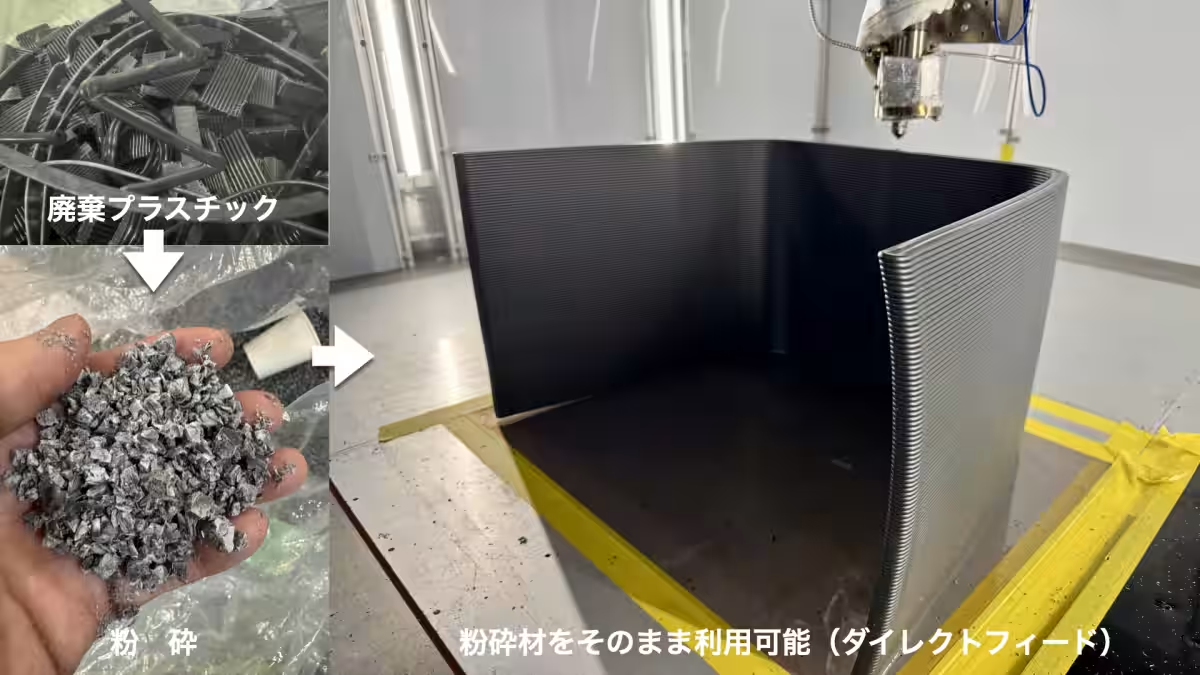

- - Unique Supply Stability Technology: To tackle the common challenges faced when working with powdered materials—like clogging and inconsistency—ExtraBold has integrated a proprietary mechanism that ensures a steady flow and reliable print quality.

- - Quality Control via Sensor Integration: Equipped with specialized cylinders and high-precision sensors, the system facilitates stable prints even with unrefined materials. Details on this technology remain confidential to safeguard ExtraBold's innovative edge.

- - Backwards Compatibility: This exciting new option will be available as a paid upgrade for existing users, allowing those already operating the EXF-12 or REX-BUTLER printers to harness the latest technology effectively.

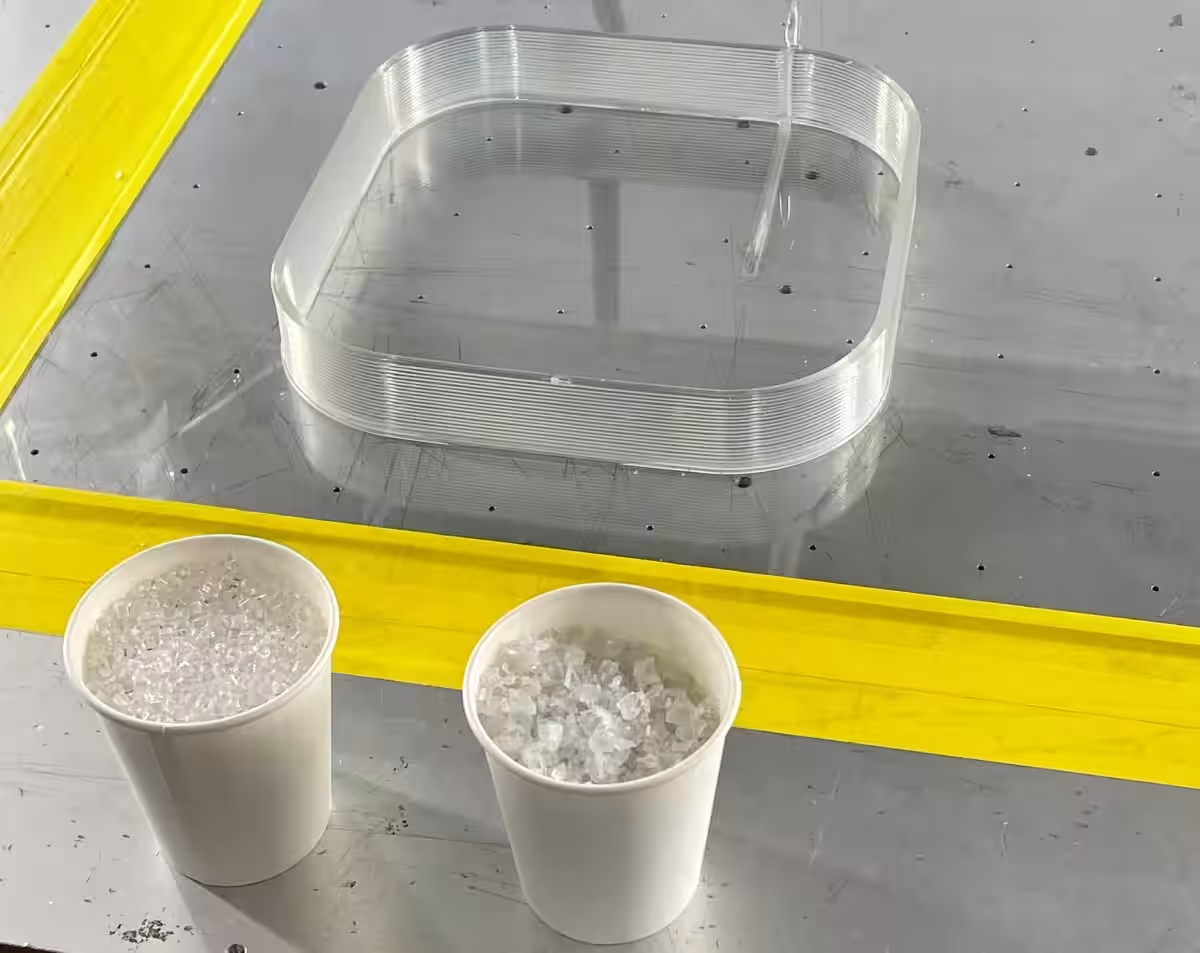

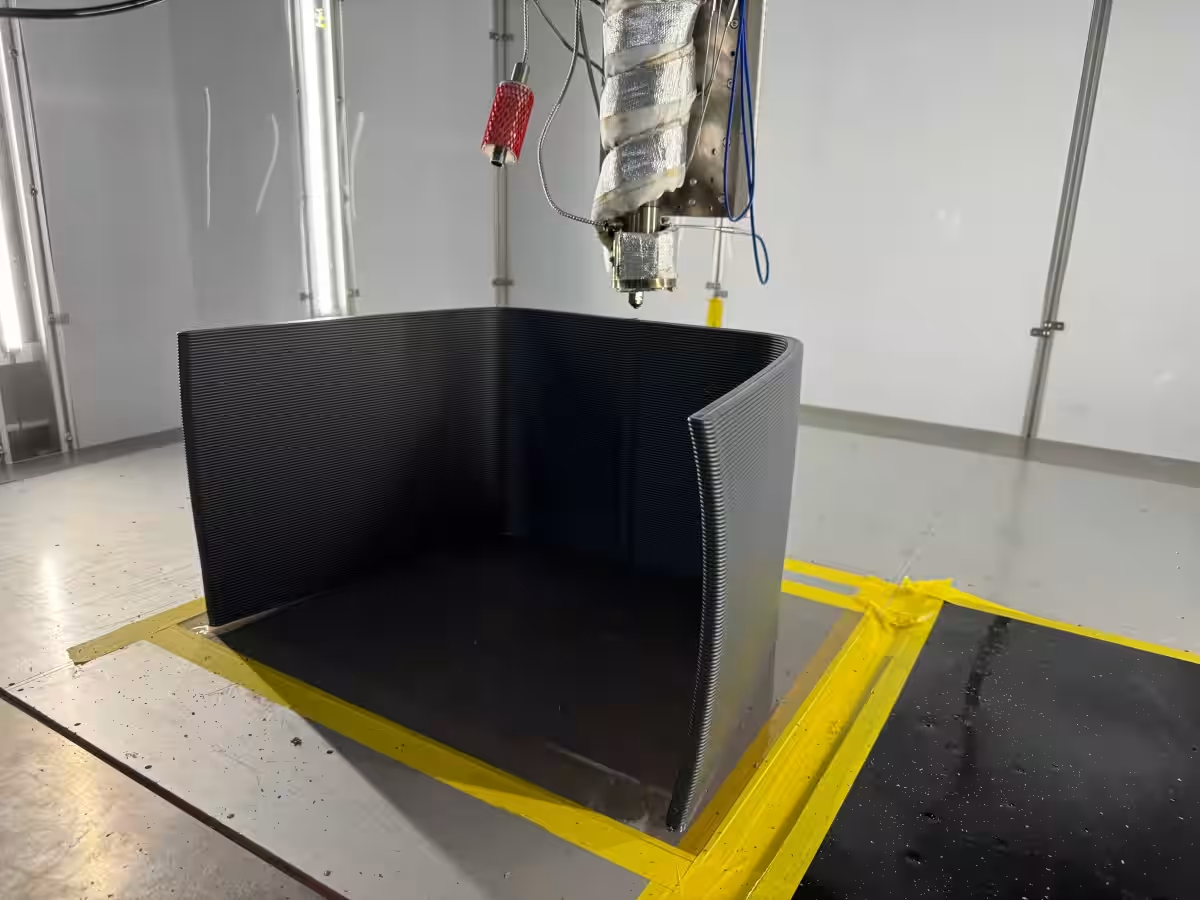

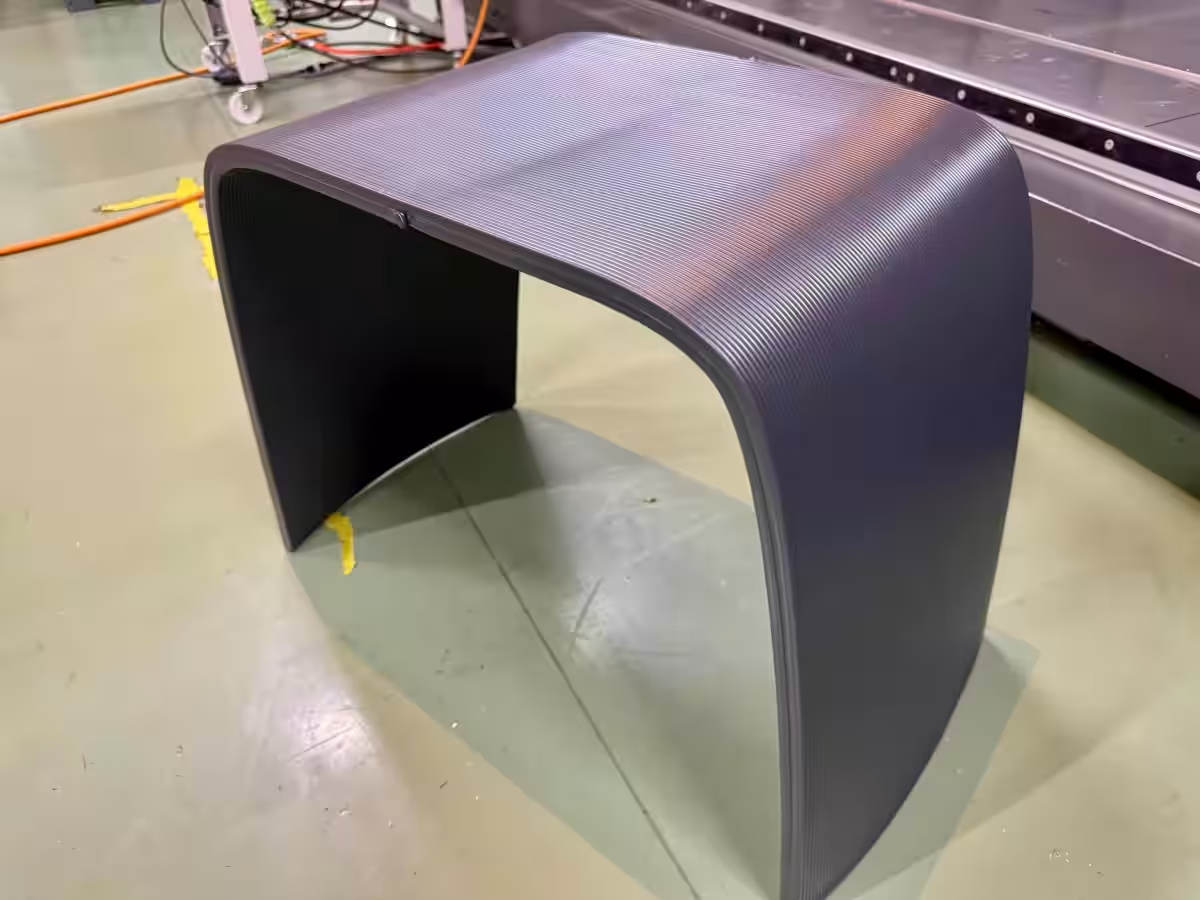

Here's a sneak peek into the testing results:

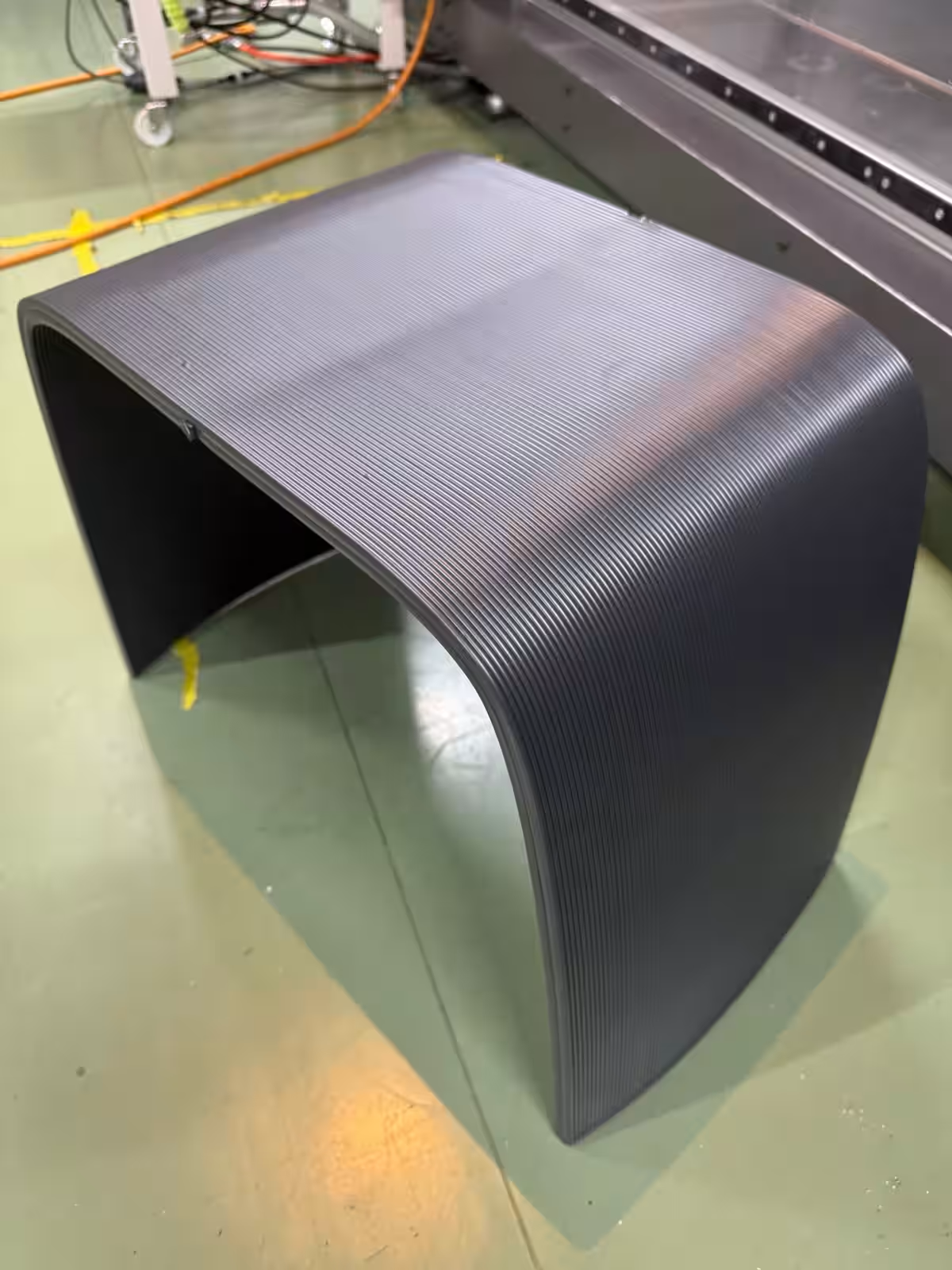

The stool shown above was printed using powdered materials, specifically a blend of recycled polystyrene and elastomer. The process took just under three hours to complete, demonstrating the efficiency and practicality of this new approach.

Future Developments and Pricing

While the pricing of the DirectFeed system has yet to be disclosed, it is expected to launch within 2025. Initially, trials will be rolled out to customers currently using the EXF-12 and REX-BITLER printers. Interested parties looking to explore these machines can reach out through ExtraBold's contact form for further inquiries or visit their website for more information.

Looking Ahead: A Commitment to Sustainability

ExtraBold is committed to promoting sustainable manufacturing practices under its umbrella of 'Green Creative™.' By enhancing the recycling efficiency of plastic waste through the DirectFeed system, the company aims to accelerate the spread of eco-friendly 3D printing technologies.

Important Note:

This feature is exclusively designed for thermoplastic materials and does not cater to other types like thermosetting resins, metals, or ceramics.

About ExtraBold

ExtraBold harnesses cutting-edge AM (Additive Manufacturing) technology, emphasizing all-Japan production while driving forward sustainable product development initiatives. The company strives to contribute to society through environmentally friendly products.

For more details, you can visit their official website: ExtraBold.

Address: 2-33-20 Kita-Otsuka, Toshima City, Tokyo, Japan 170-0004

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.