Addressing Supply Chain Risks in Manufacturing: Recent Survey Reveals Rising Threats

Understanding Supply Chain Risks in the Manufacturing Sector

In recent years, the manufacturing landscape has faced an array of unprecedented risks, primarily driven by climate change, cyber attacks, and geopolitical tensions. A comprehensive survey conducted by Spectee, a prominent startup specializing in resilience through digital transformation, highlights the urgent need for organizations to refine their supply chain risk management strategies.

The survey, encompassing insights from 500 business executives and operational staff associated with supply chains, reveals alarming trends regarding the diversification and amplification of risks affecting supply chains. With natural disasters, cyber threats, and geopolitical issues making headlines, companies find themselves confronting significant operational challenges that jeopardize business continuity.

Key Findings of the Survey

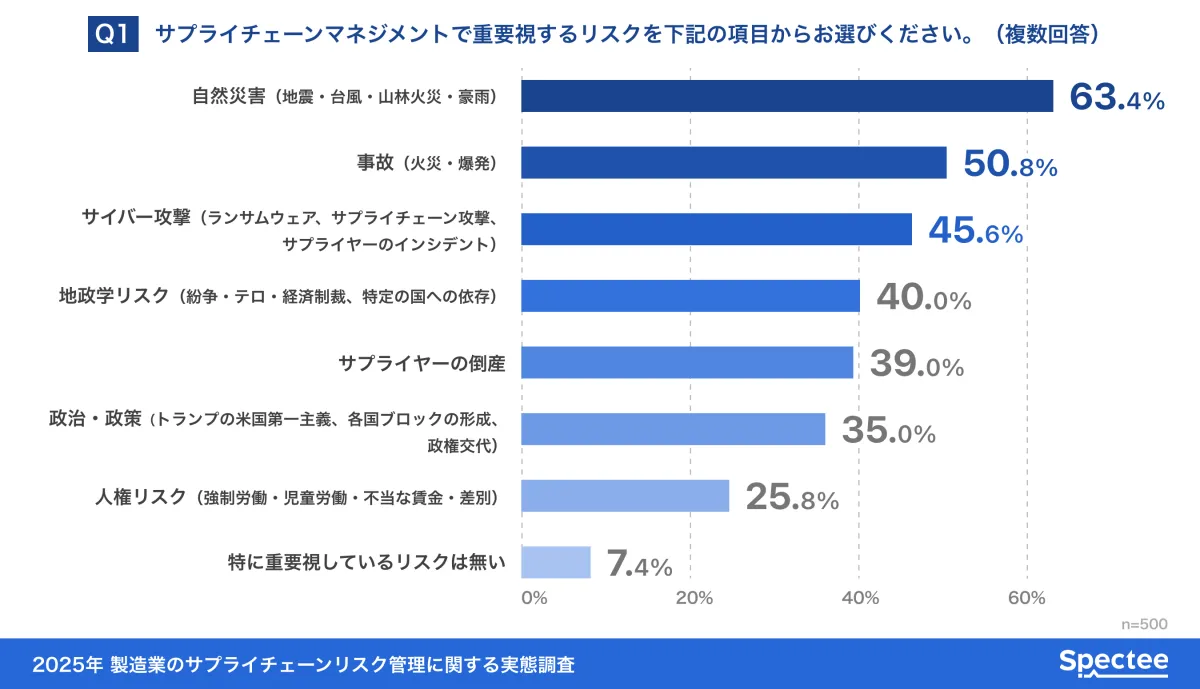

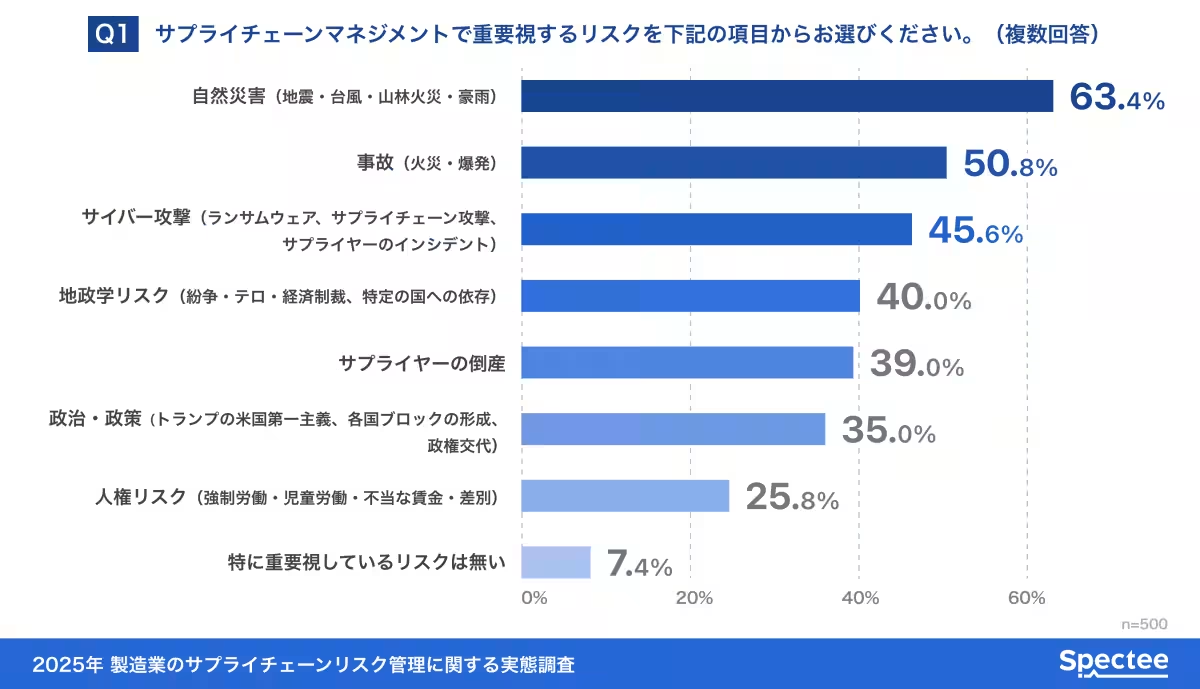

1. Natural Disasters as Primary Risks: For the second consecutive year, natural disasters are deemed the most pressing risk factor in supply chain management, cited by 63.4% of participants. Events such as earthquakes, typhoons, and floods are emerging as continuous threats, compelling businesses to prioritize disaster preparedness.

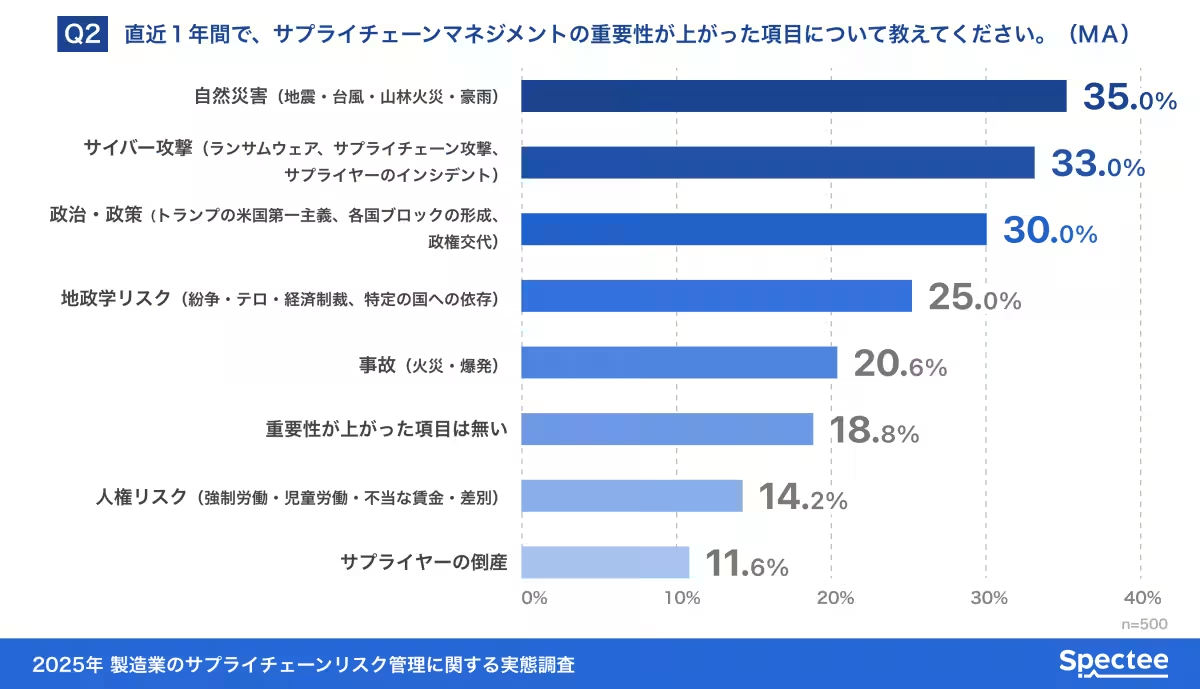

2. Increase in Cyber Attacks and Geopolitical Risks: Recent data indicates a notable rise in the importance of issues such as cyber attacks and geopolitical threats. Compared to previous assessments, concerns regarding supplier bankruptcies have surged, indicating that organizations are experiencing these risks firsthand within the last year.

3. Influence of Executive Perspectives: The survey revealed that 33.9% of respondents acknowledge that input from higher management significantly informs their risk awareness. Additionally, media coverage surrounding these threats plays a crucial role in shaping organizational views on risk relevance.

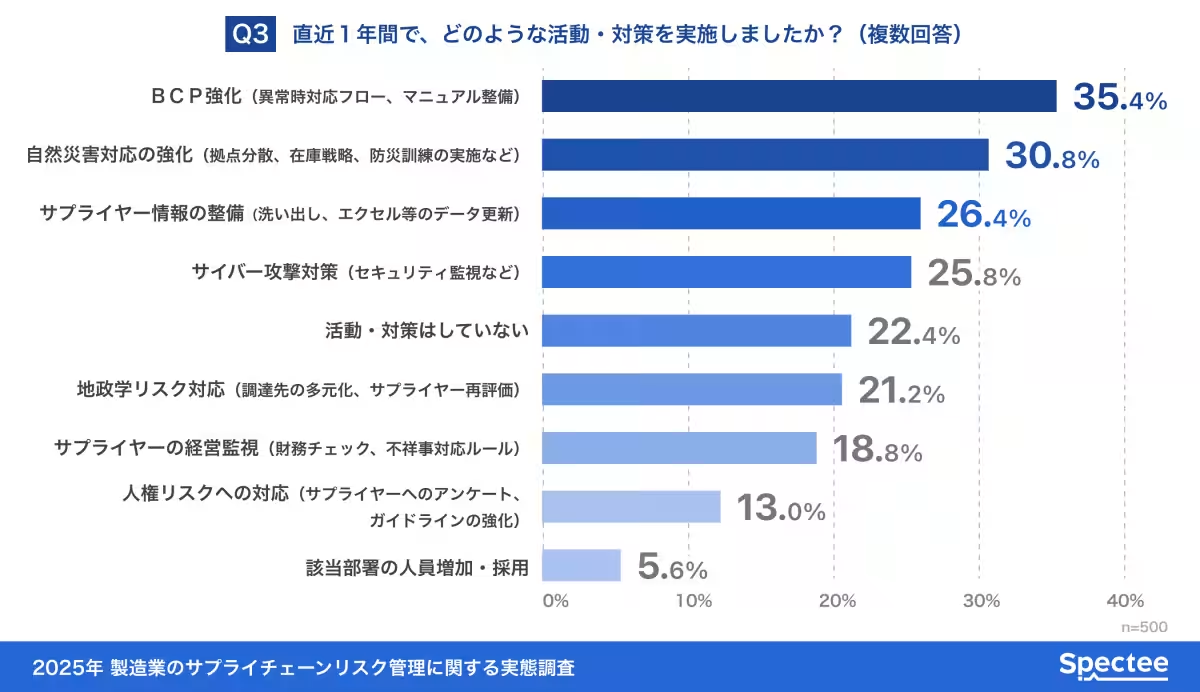

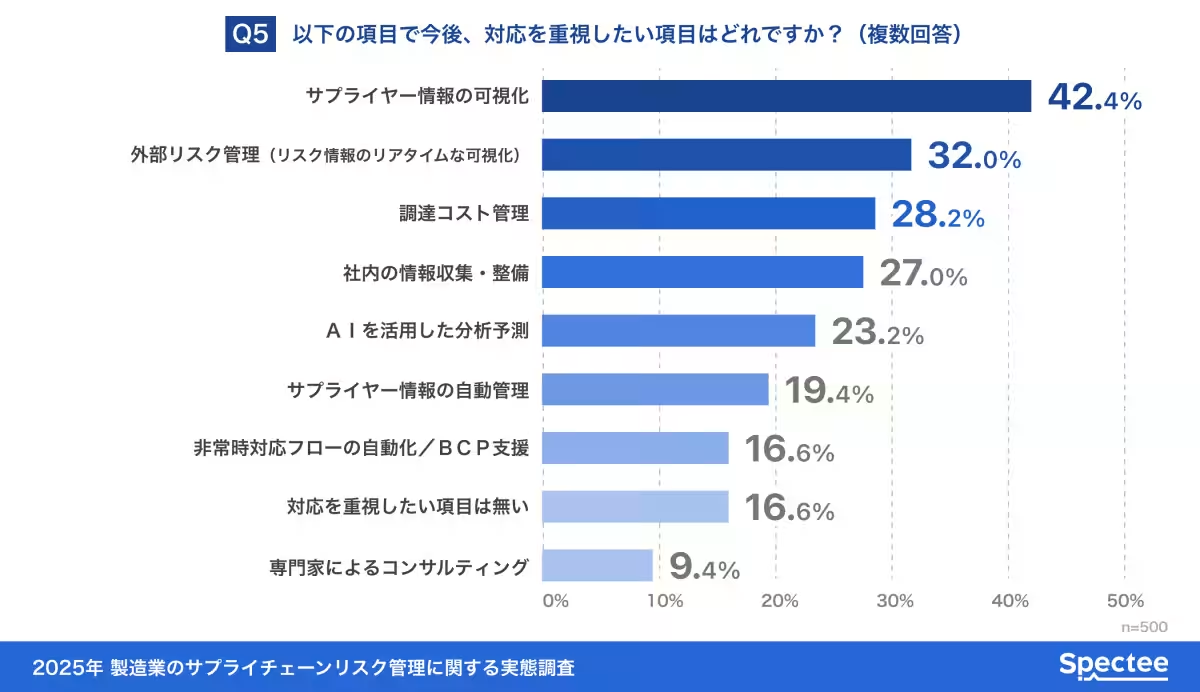

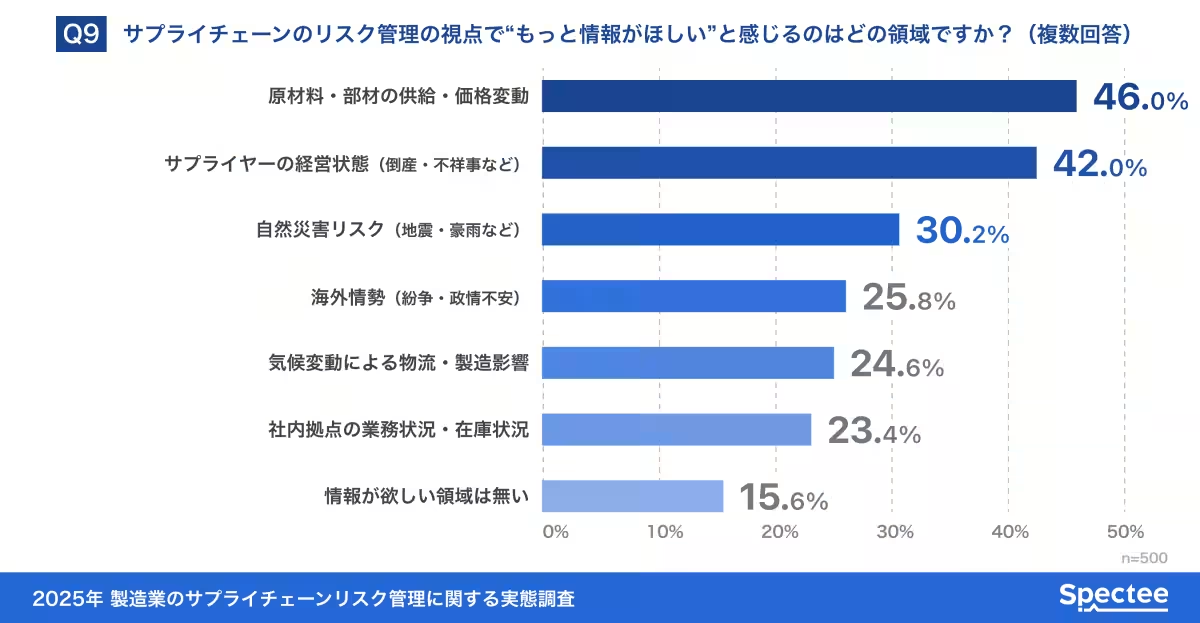

4. Challenges in Risk Management Visibility: A persistent challenge observed over the past year is the insufficient visibility of supplier information and external risk factors. Key areas where data is lacking include fluctuations in raw material supply and supplier financial health.

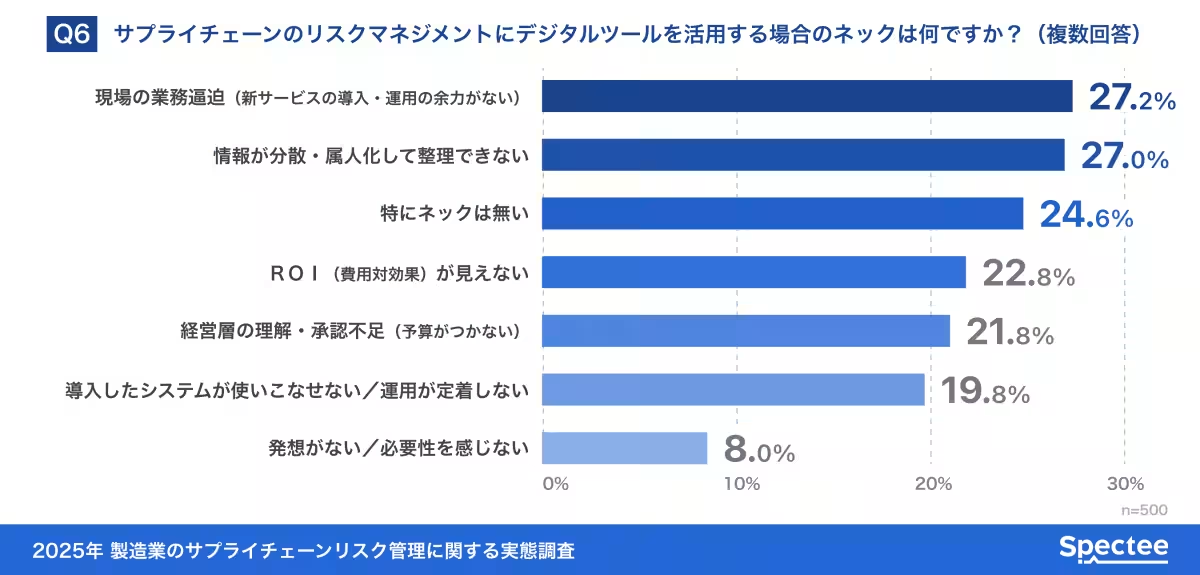

5. Barriers to Digital Tool Adoption: Firms expressed that operational constraints and the complexity of organizing information hinder their ability to implement digital solutions effectively. Concerns regarding return on investment also play a significant role in these decisions.

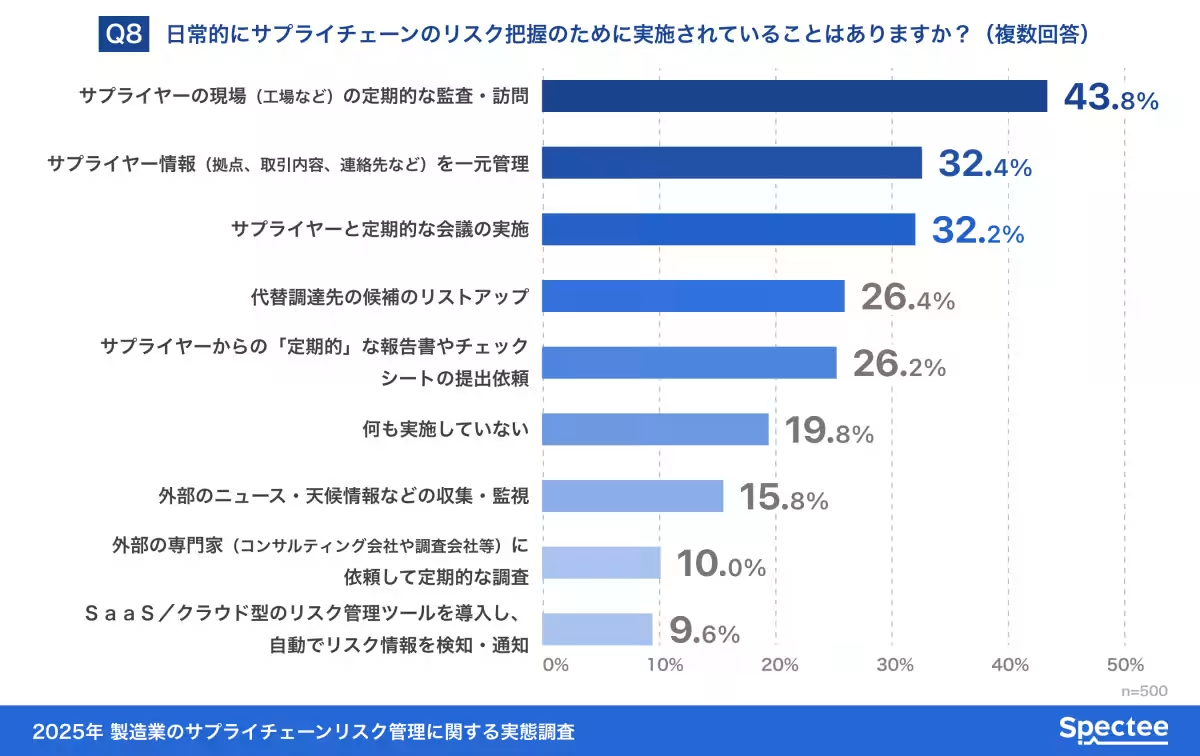

6. Preference for Traditional Risk Assessment Methods: Many companies continue to rely on conventional approaches such as audits and factory visits for risk evaluation, with less than 10% utilizing Software as a Service (SaaS) solutions for real-time risk management.

The Push for Resilience

The Spectee CEO, Mr. Kenjiro Murakami, highlighted the survey's results, stressing that amidst recent natural disasters, awareness of risks such as cyber attacks and geopolitical issues is crucial. He noted the continued reliance on manual processes for risk information gathering, suggesting a pressing need for advanced systems to enhance immediate visibility and understanding of supply chain dynamics.

Key Areas for Future Attention

Companies must focus on the visibility of supplier information and external risk management systems. The survey indicates a growing need for real-time updates regarding the risks that suppliers face, along with a push to enhance backup plans and disaster recovery processes.

In conclusion, the findings from this survey serve as a clarion call for the manufacturing industry to invest in more resilient infrastructures and adopt cutting-edge tools that facilitate timely risk assessment and information gathering. They help ensure business continuity amid the modern challenges that supply chains encounter daily. This next phase of supply chain management must marriage technology with strategies for resilience, empowering organizations to navigate uncertainties more effectively.

Topics Business Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.