SHIP Granbase Tokyo: A Revolutionary Medical Supply Logistics Hub in Chiba

SHIP Granbase Tokyo: A Revolutionary Medical Supply Logistics Hub in Chiba

The landscape of medical supply logistics is set to change dramatically with the launch of "SHIP Granbase Tokyo", a cutting-edge facility scheduled to begin operations in February 2026. This new hub, located in Funabashi City, Chiba Prefecture, will consolidate various medical logistics centers that were previously spread across the Tokyo metropolitan area. Managed by FS Unimanagement, a subsidiary of Ship Healthcare Holdings, this facility boasts an impressive floor area of 14,129 square meters (approximately 4,274 tsubo).

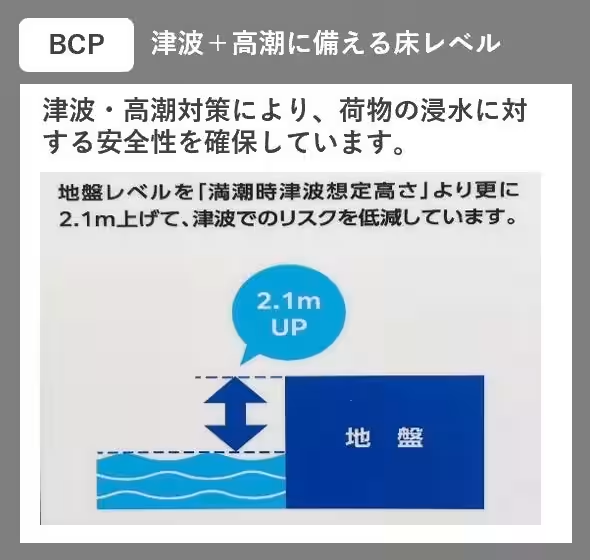

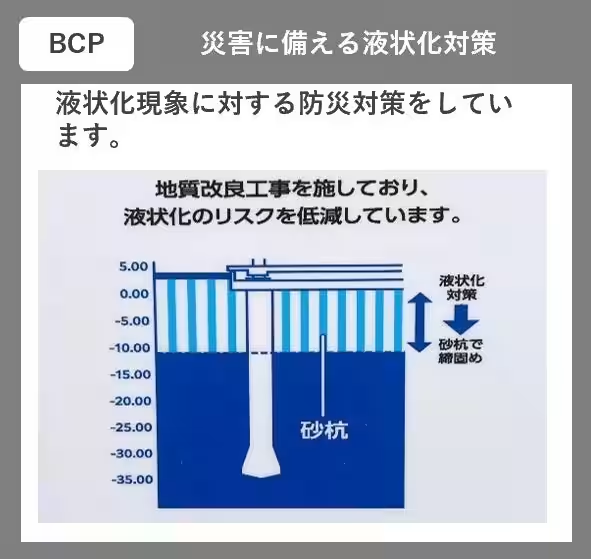

As healthcare environments continue to grow in complexity, ensuring a stable supply of medical materials is critical. SHIP Granbase Tokyo addresses this necessity by maintaining a substantial inventory prepared for emergencies. The facility has implemented a BCP (Business Continuity Planning) oriented design, featuring an earthquake-resistant structure, tsunami mitigation measures, and a 72-hour backup power supply.

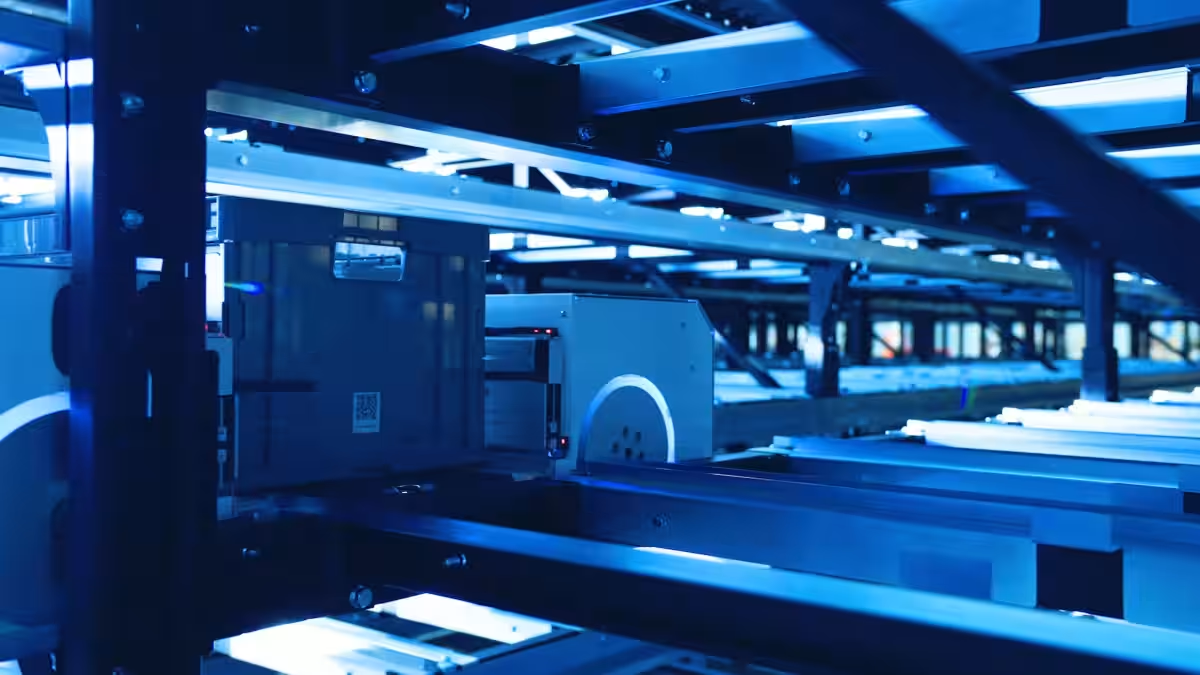

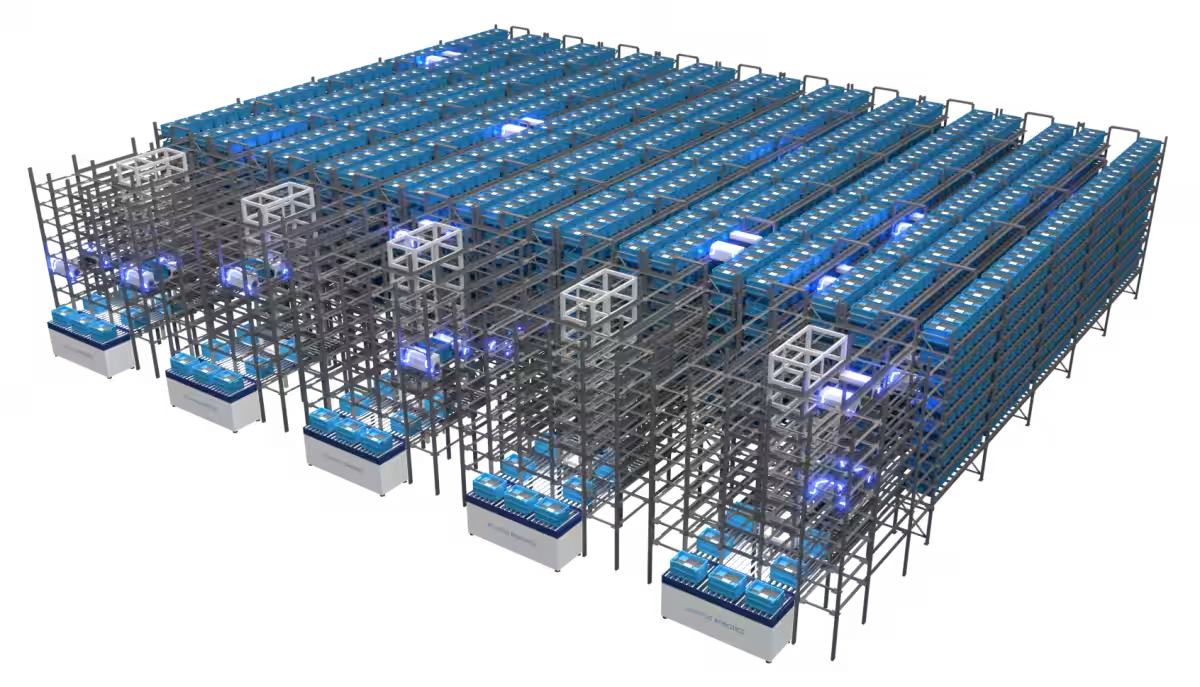

One of the standout features of SHIP Granbase Tokyo is its incorporation of the automated warehouse system "RENATUS", developed by RENATUS ROBOTICS. This advanced logistics hub utilizes artificial intelligence, robotics, and RFID technology to enhance efficiency and safety during the material supply process. This integration signifies a leap toward next-generation logistics operations capable of meeting the challenges of modern healthcare demands.

The SHIP Granbase Tokyo is strategically positioned about 2.2 km from the Yatsu Funabashi Interchange and just 9 minutes on foot from the JR Keiyo Line Minami Funabashi Station, ensuring excellent accessibility for partner healthcare institutions. The facility will support around 60 medical facilities, including major university hospitals and core hospitals with 100-500 beds, capable of managing approximately 70,800 different items.

Collaborative Efforts with Nippon Express

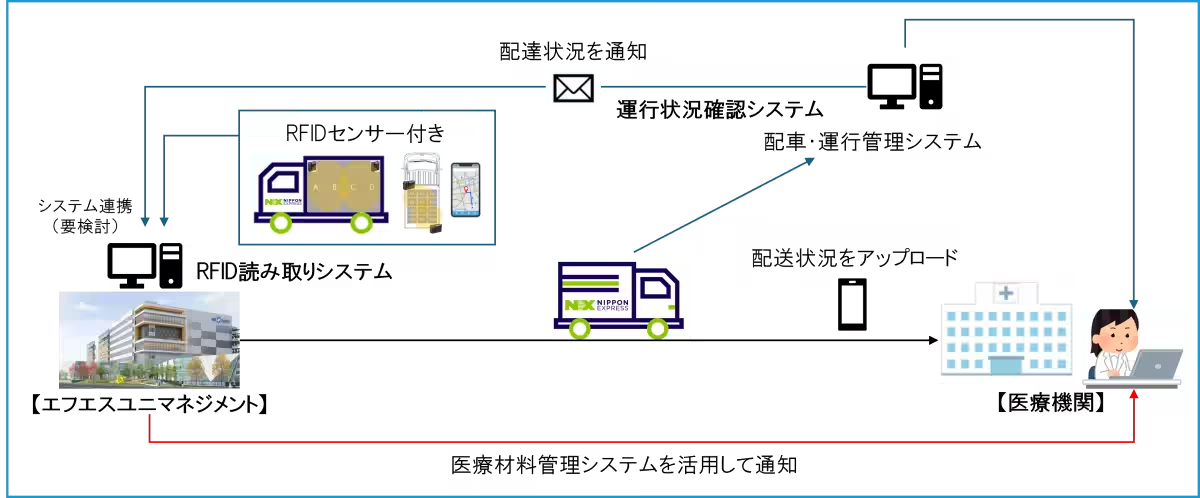

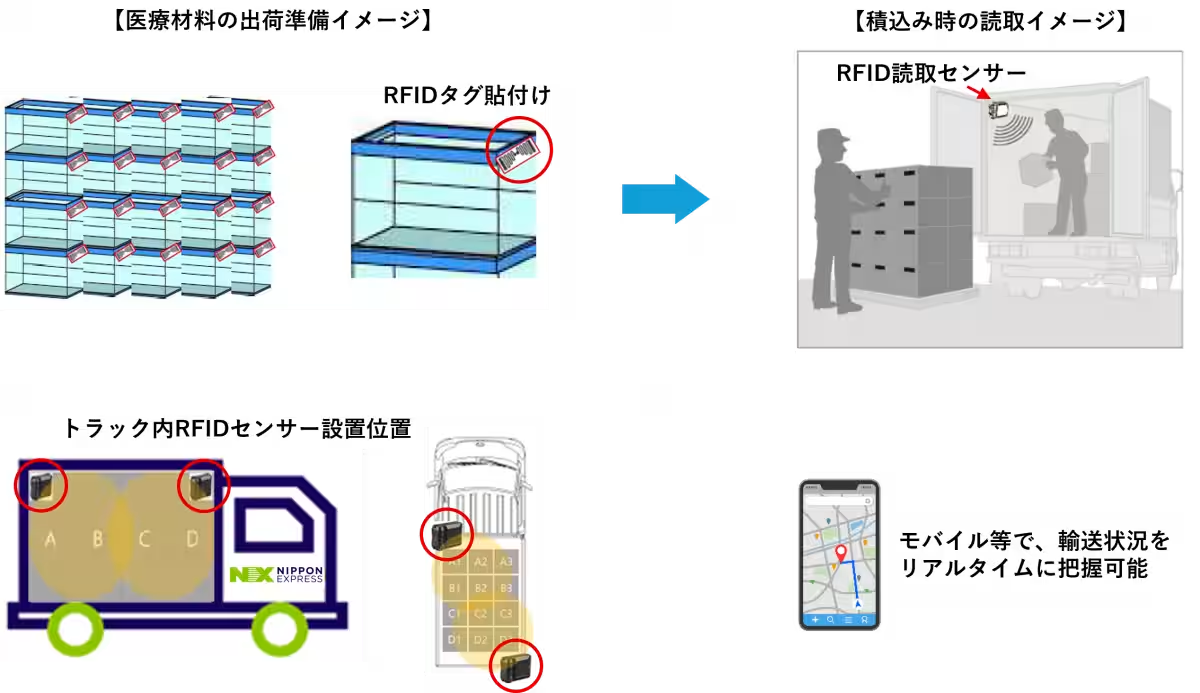

To strengthen the traceability of medical materials, SHIP Granbase Tokyo has teamed up with Nippon Express to develop a tracking system utilizing RFID tags affixed to medical supplies. These tags will ensure real-time tracking from the moment goods leave the facility until they reach their destinations. This collaboration aims to resolve various logistical challenges such as reducing transportation frequency, minimizing paperwork, cutting waiting times, and alleviating management burdens, all while promoting a safe and sustainable society.

The commitment to using RFID technology will streamline operations, helping prevent issues like missed or incorrect shipments and simplifying verification processes. By establishing a real-time transportation management system, SHIP Granbase Tokyo aims to create a seamless flow of supplies critical for healthcare facilities, especially during emergencies.

Facility Features and BCP Measures

The new logistics hub is designed with multiple BCP measures, including an earthquake-resistant building structure that anticipates potential tsunamis and ground liquefaction. In the event of a power outage, the facility is equipped to remain operational for a minimum of 72 hours, ensuring continuous supply chain functionality. This proactive approach will facilitate collaboration with the Osaka Solution Center, ensuring that supply disruptions during disasters are minimized, thereby allowing for robust and reliable medical supply chain operations.

Key Functions of the Automated Warehouse System

The SHIP Granbase Tokyo facility will feature a fully automated warehouse capable of receiving, storing, and dispatching medical items efficiently. Orders from hospitals will be processed through an RFID-driven automated management system, ensuring accurate inventory control and timely deliveries. This system allows for seamless integration with hospital inventory management, automating purchase orders to suppliers based on current stock levels.

Incoming items will undergo automated inspections and sorting before being transferred to the appropriate storage locations or dispatched to medical facilities. The system's precision tracking capabilities promise to enhance the accuracy and reliability of logistics operations, providing a “no inspection” delivery guarantee by achieving an astounding 99.999999% accuracy rate.

Fostering a Culture of Continuous Improvement

With SHIP Granbase Tokyo, FS Unimanagement not only commits to improving logistics processes in the healthcare sector but also plays a crucial role in supporting the challenging financial conditions hospitals face today. By increasing operational efficiency and reducing costs, this facility is set to significantly bolster the quality of medical care provided to communities.

In summary, SHIP Granbase Tokyo emerges as a pioneering project aimed at transforming healthcare logistics in the region. By leveraging cutting-edge technologies and strategic partnerships, the facility promises enhanced efficiency, safety, and reliability in supplying essential medical materials and managing healthcare logistics.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.