Introducing the Innovative SVP-1 Food Sterilization Device by Nakani Manufacturing

Introduction

In a groundbreaking move for the food industry, Nakani Manufacturing, a leading equipment manufacturer in Japan, has announced the launch of their new food sterilization device, the SVP-1, which is set to begin sales in April 2025. This innovative product utilizes superheated steam to provide an effective sterilization process without the use of chemicals, ensuring both safety and quality in food preparation.

Development Background

The need for effective sterilization solutions has become increasingly pressing in the food industry. Traditional methods often rely on chemical agents that can leave residues or may not adequately address certain food items, such as sliced vegetables that are difficult to sterilize effectively. In response to these challenges, Nakani Manufacturing embarked on the development of the SVP-1, creating a device that delivers high sterilization performance while preserving the original texture of food products.

Key Features

Instant Sterilization

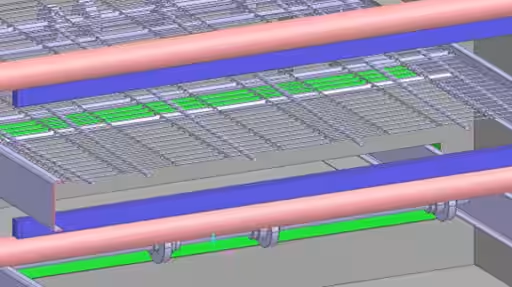

The SVP-1 employs a unique slotted nozzle design that allows high-speed jets of superheated steam to be directed in both vertical and horizontal positions. This technique instantly heats the surface of food items, killing bacteria upon contact. This feature is especially beneficial for food safety, ensuring quick processing with minimal disruption to the ingredients.

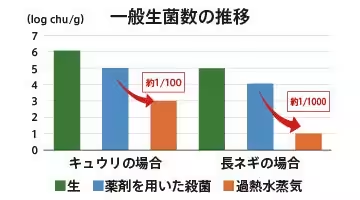

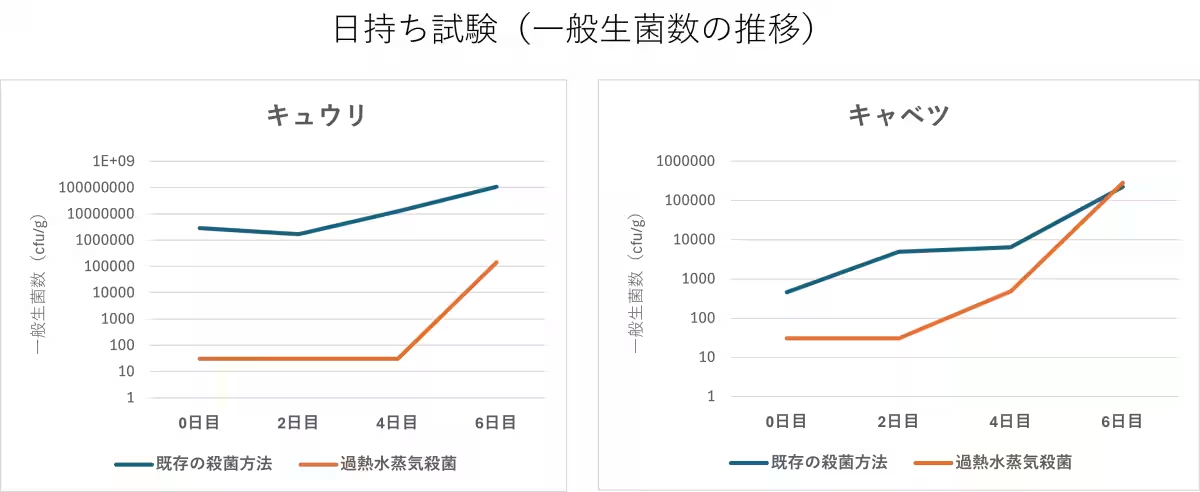

Significant Bacterial Reduction

Compared to existing sterilization methods, the SVP-1 has demonstrated a substantial reduction in bacterial counts. Testing has indicated that controlling initial bacterial levels contributes to decreased pathogen growth during refrigerated storage. This capability promises to enhance the shelf life of various produce, providing an attractive solution for businesses concerned about freshness.

Given the conditions of shelf life testing, when compared to traditional sodium hypochlorite methods, the SVP-1 showed remarkable efficacy at boiling temperatures of 200℃, thus assuring food producers of a reliable sterilization process.

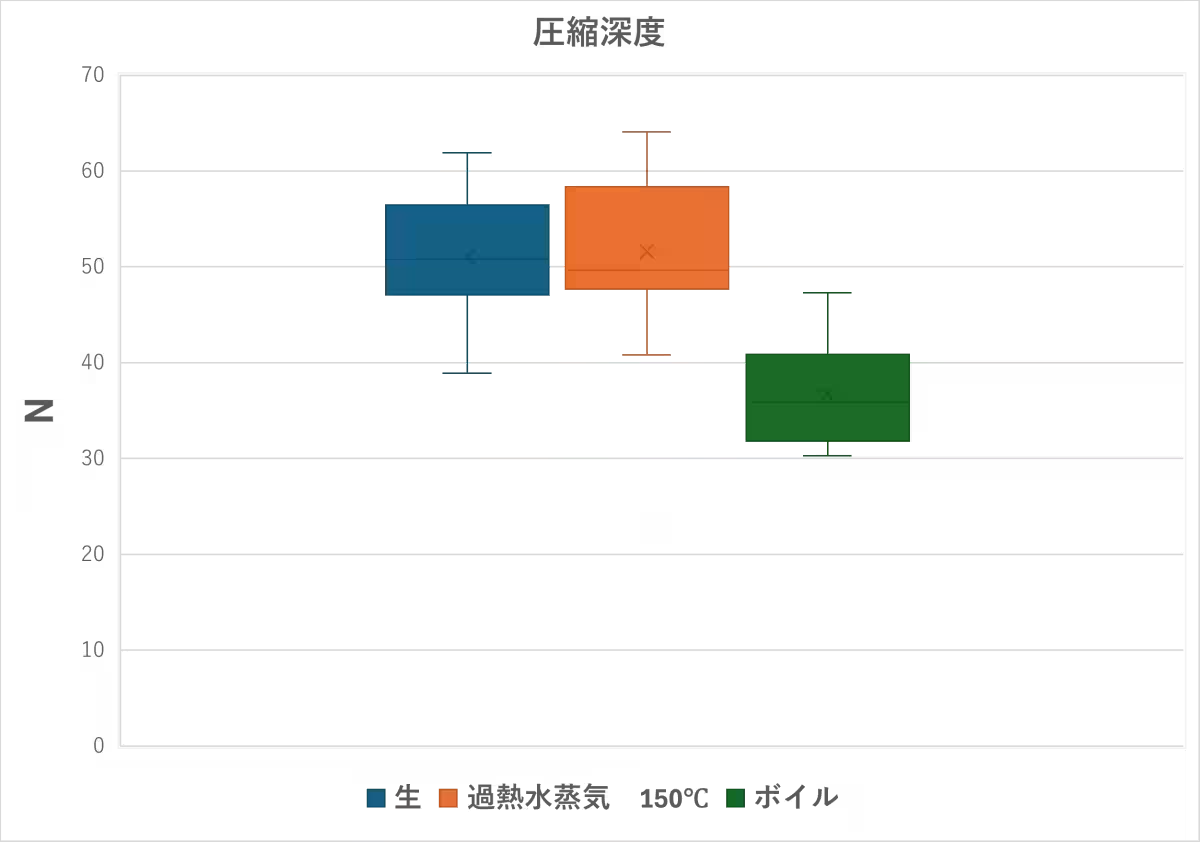

Texture Preservation

One of the standout advantages of the SVP-1 is its ability to maintain the original hardness and texture of food products during sterilization. Tests measuring the pressure load on food items revealed that the integrity of the texture is almost entirely preserved post-treatment, confirming that the sterilization process does not compromise quality.

New Possibilities in Food Processing

By utilizing superheated steam without chemicals, the SVP-1 introduces a new paradigm for food sterilization and processing. Nakani Manufacturing is positioned to redefine standards in the food production sector, enhancing the safety and quality of meals in kitchens, schools, hospitals, and restaurants alike.

Upcoming Exhibitions

Nakani Manufacturing will demonstrate the SVP-1 at FOOMA JAPAN 2025, taking place from June 10 to 13. Attendees are encouraged to visit booth No. 東5P-38 in Hall 3, where they can explore this and other innovative technologies aimed at transforming the future of food production.

Product Specifications

- - Device Name: SVP-1 Food Sterilization Device

- - Dimensions (mm): 1650 (W) x 1230 (D) x 1400 (H)

- - Conveyor Opening: 600 (W) x 70 (H)

- - Rated Power Consumption: 5.06 kW (three-phase 200V)

- - Steam Consumption: Up to 70 kg/h at 0.4 MPa

Note: This device drastically reduces bacterial counts but does not achieve sterilization. Specifications and appearance are subject to change without notice for quality improvements.

About Nakani Manufacturing

Established in 1946, Nakani Manufacturing has earned a reputation as a professional kitchen equipment manufacturer, specializing in the production and sale of kitchen solutions for institutional meal providers. The company's commitment extends to assisting hospitals, welfare facilities, business cafeterias, and large restaurant chains, ensuring efficient and safe cooking environments for all.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.