ReTA BASE Develops Innovative Monofilament from Recycled Bottle Caps

The Innovative Journey of ReTA BASE's Monofilament

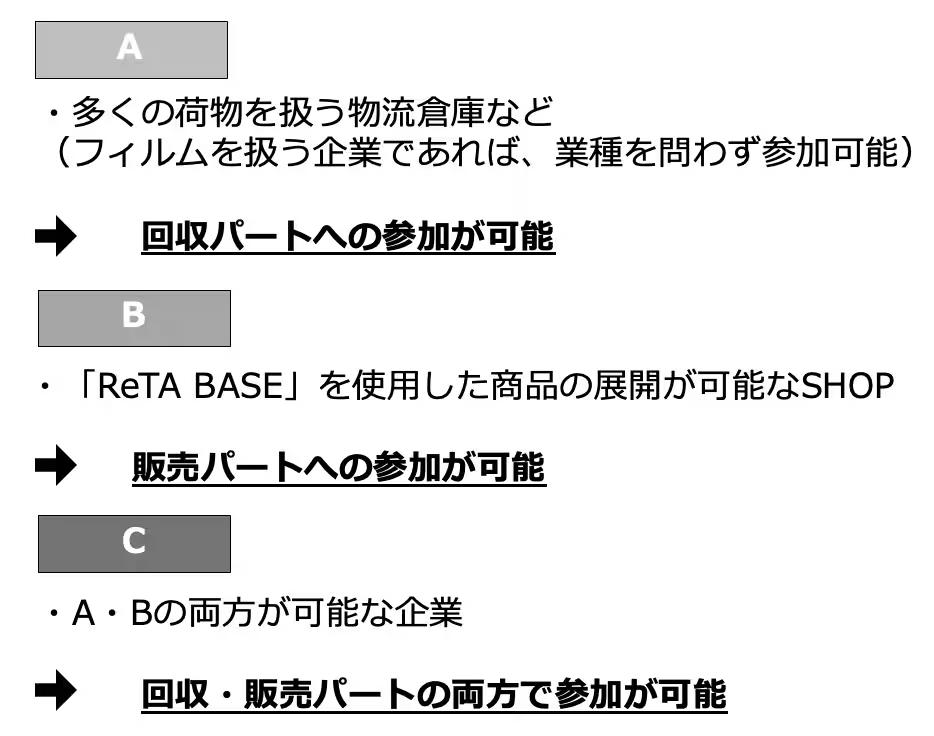

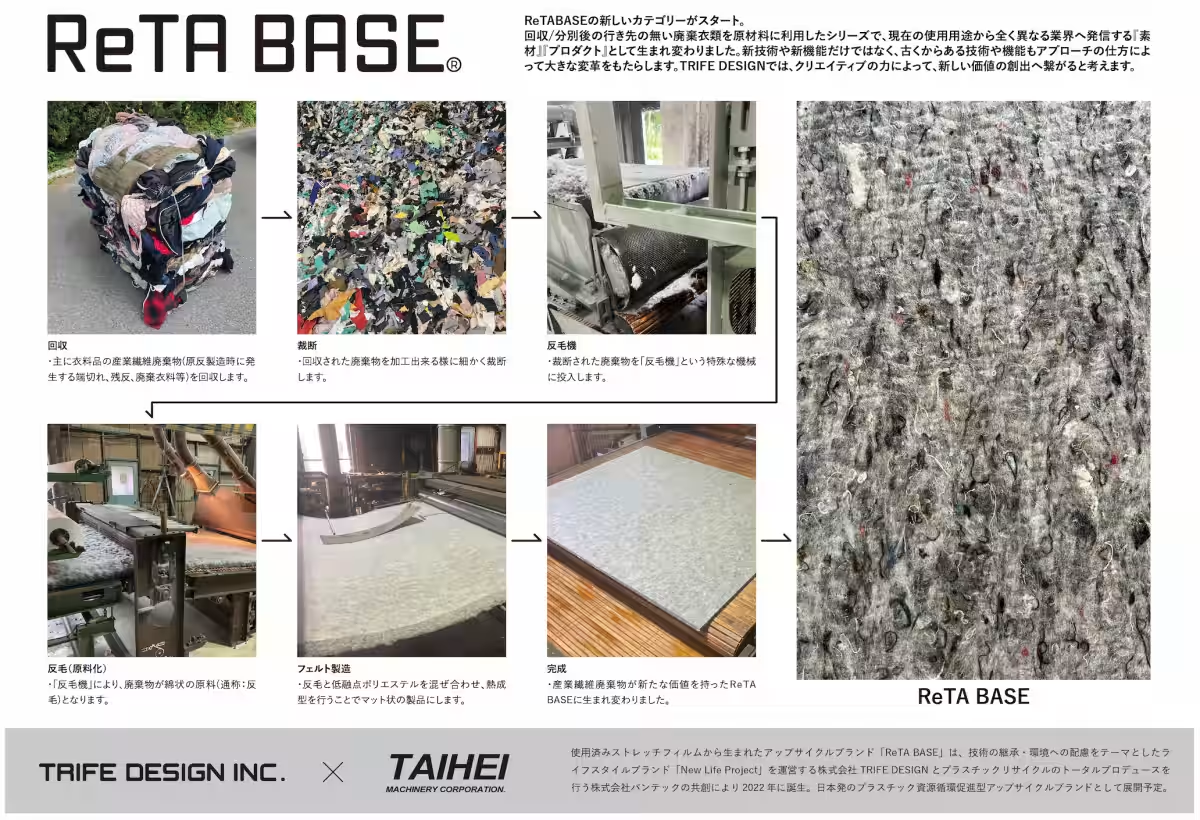

In a significant step towards sustainability, ReTA BASE, Japan's pioneering upcycling brand, has launched a groundbreaking material known as monofilament, made partially from recycled PET bottle caps. This venture aims to contribute to waste reduction and address the pressing issue of plastic waste by turning discarded materials into valuable resources. The project is not just innovative but symbolizes a collaborative effort in the quest for a sustainable future.

Operated by TRIFE DESIGN, located in Tokyo, ReTA BASE collaborates with partners like Nihon Yamamura Glass Co. from Hyogo and Innovex from Tokyo to bring this new material to life. The utilization of plastic waste, specifically polyethylene and polypropylene from discarded bottle caps, stands out as a key feature of this endeavor, pushing the boundaries of recycling and material science.

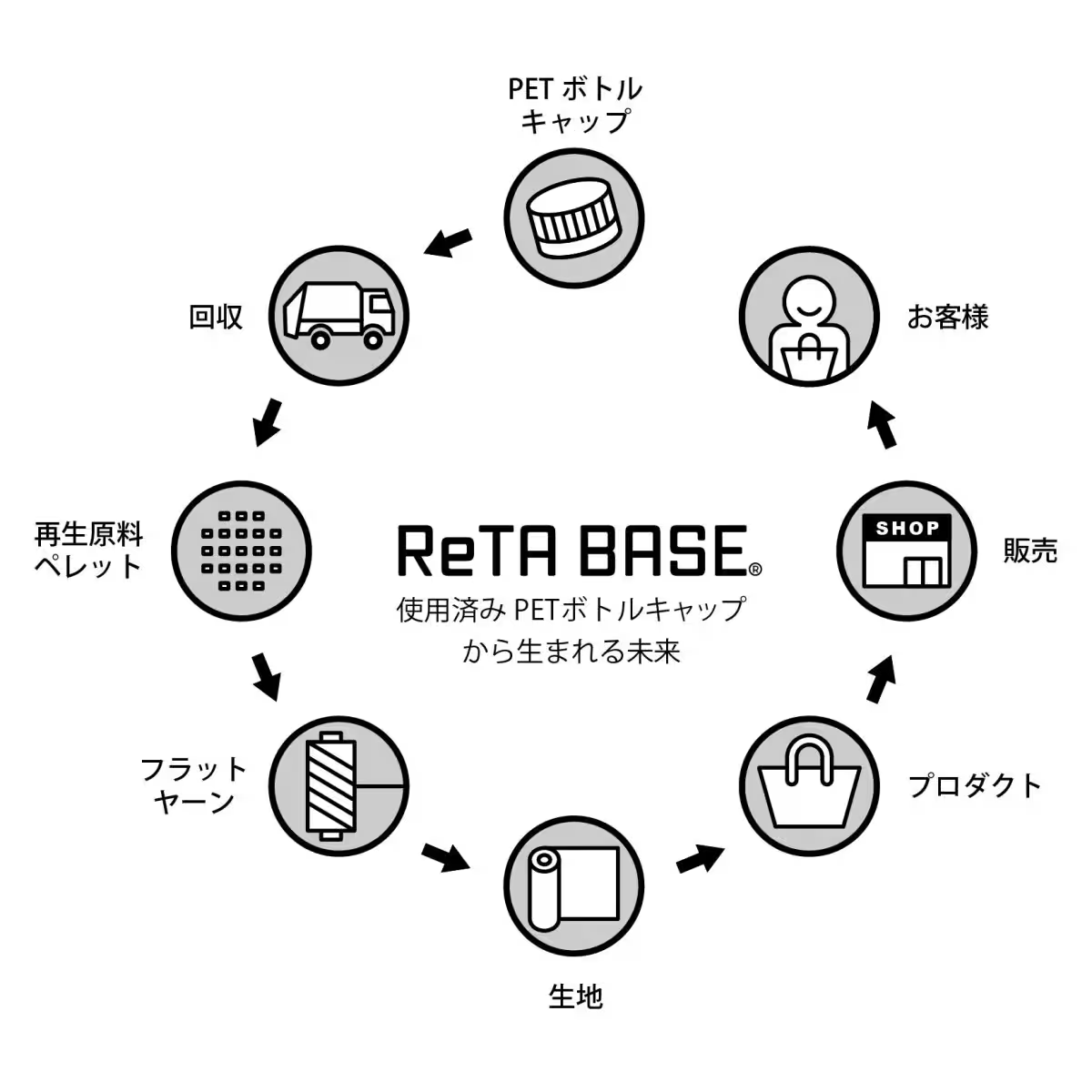

The Circular Model

The newly developed monofilament showcases a fully domestic circular model, aiming to minimize environmental impact by keeping the entire recycling process within Japan. By doing so, the initiative not only reduces transportation costs but also promotes regional economic revitalization. The overarching goal is to address global environmental challenges caused by plastic waste, showing how different industries can unite for a common purpose.

Traditionally, manufacturing from resin involves the costly process of injection molding, which can be hindered by high initial costs for molds. However, the innovative transition to monofilament development opens new avenues for product creation without the need for complex mold systems, making production more accessible.

Crafting this new monofilament came with challenges, particularly as it was the first of its kind made from PET bottle caps. Establishing a reliable manufacturing process required significant time and expertise. Continuous collaboration between TRIFE DESIGN and its partners has been pivotal in achieving a stable and eco-friendly product.

The Road Ahead

With a keen focus on sustainability, ReTA BASE plans to apply the newly developed monofilament across various products like lifestyle goods, bags, and sheets. This broader application enhances the potential of recycled materials in everyday products, thereby encouraging a shift towards responsible consumption.

What is ReTA BASE?

The name ReTA embodies the concept of mutual benefit, where the happiness of the self is intertwined with that of others, reflecting the project's ethos. ReTA BASE not only serves as a brand but also as a platform for collaborative efforts in sustainable development.

Previous Initiatives

ReTA BASE has been making strides in upcycling through various initiatives since its inception. In 2022, it began with a project utilizing recycled stretch film in collaboration with Pantech, and in 2023, they expanded their efforts by incorporating discarded clothing that had no other recourse. The development of recycled polyethylene cloth from bottle caps showcases the project's versatility and commitment to sustainability.

Future Innovations

As ReTA BASE moves forward, they intend to further innovate and develop new ways to incorporate recycled materials into everyday lives. The ongoing partnership with various companies ensures a continuous flow of ideas and resources, making ReTA BASE a dynamic player in the realm of upcycling and sustainability.

By championing responsible practices and innovative solutions, ReTA BASE is paving the way for a more sustainable tomorrow — one monofilament at a time.

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.