Innovative Development of Flame-Retardant Prepreg Using Biomass PFA for Aircraft Interiors

Introduction

Sumitomo Bakelite Co., Ltd., headquartered in Shinagawa, Tokyo, spearheaded an innovative initiative aimed at supporting the aviation industry’s ambitious goal of achieving net-zero CO2 emissions by 2050. This initiative centers around the development of a flame-retardant prepreg composed of biomass-derived PFA (PolyFurfuryl Alcohol), commonly known as furfuryl resin. This new product addresses the pressing need for environmentally sustainable materials in aviation interiors while ensuring high safety standards.

Development Background

The aviation sector is vigorously pursuing decarbonization strategies, aligning with the carbon-neutral targets set by organizations such as IATA (International Air Transport Association) and ICAO (International Civil Aviation Organization). Many key aircraft manufacturers are focusing on reducing their carbon footprint. In light of the ongoing movement towards lightweight composite materials like FRP (Fiber Reinforced Plastic), reducing reliance on petroleum-derived materials has become a significant challenge, especially for thermosetting resins that are often not recyclable. Therefore, the application of biomass raw materials is being explored to mitigate environmental impact, necessitating new solutions across the entire supply chain.

Our Approach and Product Features

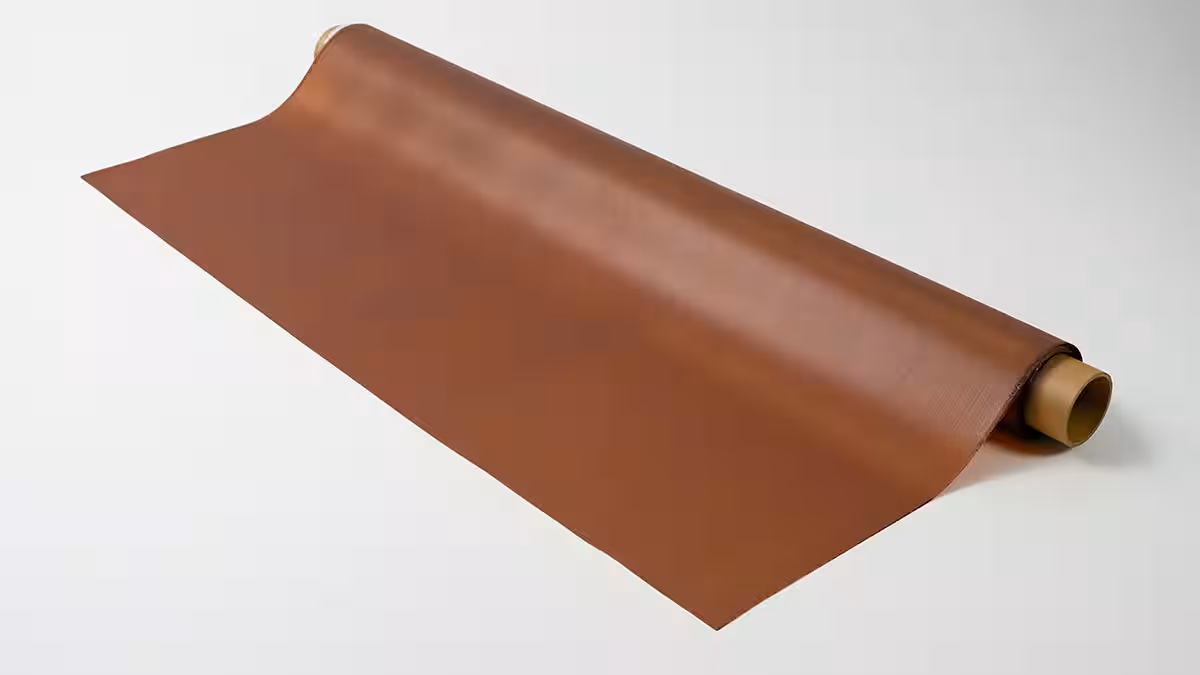

At Sumitomo Bakelite, we have branded our biomass-derived non-edible PFA and its associated products as "sbPFA®". In this context, we developed a PFA prepreg utilizing PFA resin as a binder. This product is positioned as a key solution supporting the aviation industry’s decarbonization efforts, driving both CO2 reduction and sustainable product development. The sbPFA® prepreg meets the rigorous requirements for flame resistance, low smoke emissions, and low toxicity (FST) standards, while maintaining mechanical strength comparable to traditional petroleum-based phenolic resins. Additionally, performance testing, such as the OSU heat release test in compliance with 14 CFR Part 25, has shown that sbPFA® performs at a level on par with conventional phenolic resins.

sbPFA® Prepreg

Further, by developing the entire process from PFA polymerization to prepreg fabrication, we achieved a 43% reduction in carbon footprint (CFP) compared to existing products. This advancement enables the simultaneous achievement of lower environmental impact and improved safety. The sbPFA® prepreg contributes significantly to applications requiring flame retardancy, including aircraft interiors and automotive batteries.

Benefits of Introducing sbPFA®

1. Environmental Impact Reduction and Enhanced Corporate Value

Achieving a 43% reduction in CFP, which was challenging with traditional phenolic resin prepregs, greatly supports the 2050 carbon neutrality goal of the aviation industry. This accomplishment also fosters improved ESG ratings and brand image for corporations. The adoption of non-edible biomass raw materials facilitates sustainable sourcing, reinforcing environmental considerations throughout the entire supply chain.

2. High Safety and Compatibility with Existing Processes

While ensuring excellent FST performance essential for aircraft interiors, the sbPFA® prepreg can be handled in the same manner as traditional phenolic resins. Consequently, manufacturers can continue producing high-safety products without needing significant investments in new equipment or substantial modifications to their production processes, thus maintaining manufacturing efficiency.

Contribution to a Sustainable Society

The development of sbPFA® prepreg significantly contributes towards the Sustainable Development Goals (SDGs), particularly Goal 12: Responsible Consumption and Production. By utilizing non-edible biomass PFA resin, we reduce CFP by 43%, enhancing resource efficiency and lowering environmental burdens—fulfilling our responsibility to produce sustainably. Moreover, the superior FST performance improves safety and enhances societal security and well-being. Sumitomo Bakelite remains committed to tackling global challenges through continuous innovation in environmental technology and building partnerships.

Future Plans

Currently, the sbPFA® product is in its prototype stage, with sample distributions underway to selected aircraft manufacturers. As we focus on customer evaluations, we aim to begin full-scale production by 2028. Furthermore, we plan to extend its application beyond the aviation sector to include any area requiring flame-retardant materials, such as automotive batteries, effectively bolstering our marketing activities.

Contact Information

For inquiries, please reach out to:

Sumitomo Bakelite Co., Ltd.

Materials Solutions Sales Division, Marketing Department

Tel: 03-5462-4204

Inquiry Form: Contact Us

Topics Consumer Products & Retail)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.