Takaya Inc. Launches Free RFID Encoding Software to Replace Barcodes by 2025

Takaya Inc. Launches Free RFID Encoding Software

Takaya Inc., based in Okayama Prefecture, Japan, has announced the upcoming availability of its free RFID encoding software, set to launch on April 30, 2025. This innovative initiative aims to encourage businesses currently using barcode systems to adopt RFID technology, enhancing operational efficiency and accuracy across various fields, particularly in logistics and inventory management.

Background and Need for Transition

In recent years, the adoption of RFID technology has surged, primarily driven by the demand for more reliable and efficient management systems that traditional barcodes cannot support. Though RFID technology presents significant advantages, such as improved accuracy and time savings, initial high costs, including specialized label printers and complex software systems, have deterred many companies from making the switch. To address these challenges, Takaya's RFID encoding software is designed to streamline the transition and make RFID implementation accessible for more organizations.

This software allows easy data integration from existing barcode systems or CSV files, enabling users to encode information onto RFID tags intuitively. With this tool, companies can quickly explore Proof of Concept (PoC) implementations, significantly lowering the barriers to entry for RFID technology.

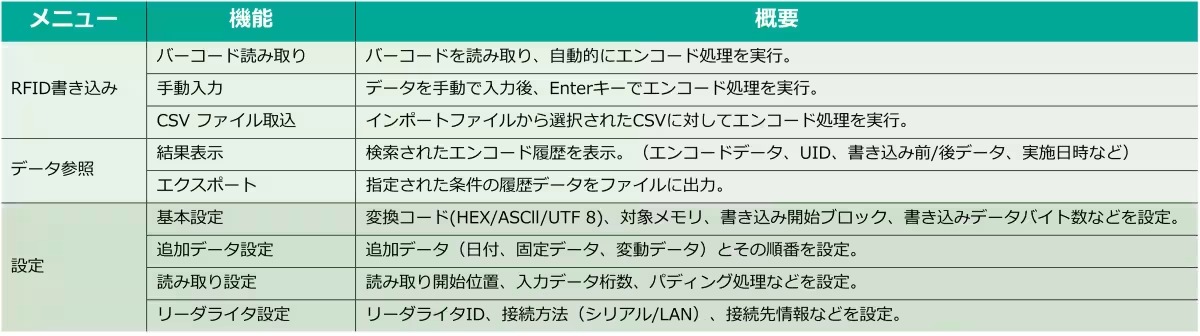

Features of the RFID Encoding Software

- - Direct Writing of Barcode Data: The software supports efficient writing of existing barcode data directly onto RFID tags.

- - CSV File Import: Users can easily import data from CSV files for quick RFID tag assignment.

- - Keyboard Input: Manual input of data for encoding onto RFID tags is also possible.

- - Add Data Capabilities: Users can add additional data to the original encoding as needed.

- - Encoding History: The software tracks encoding history with CSV export functionality for record-keeping.

Overview of Operations

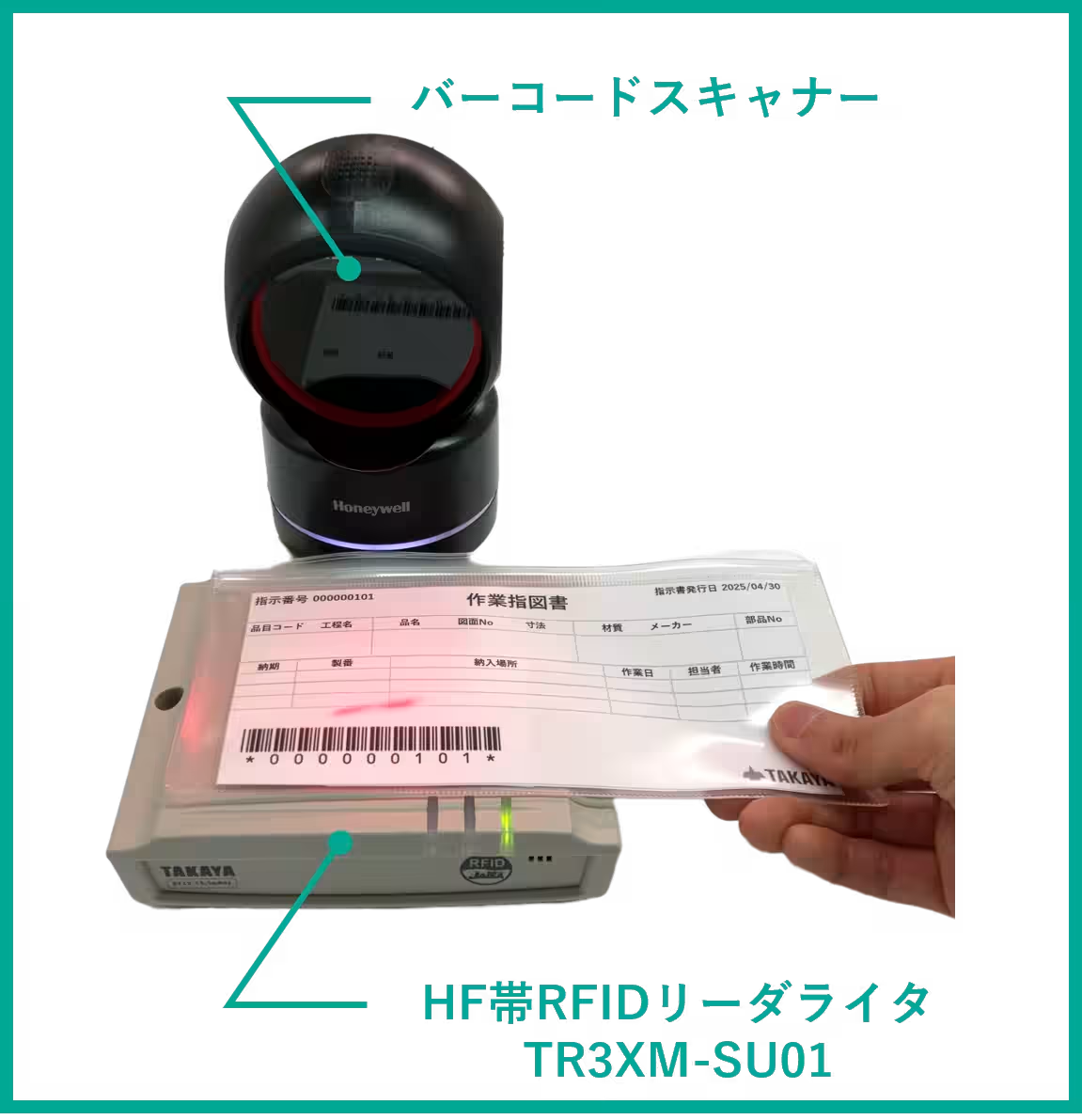

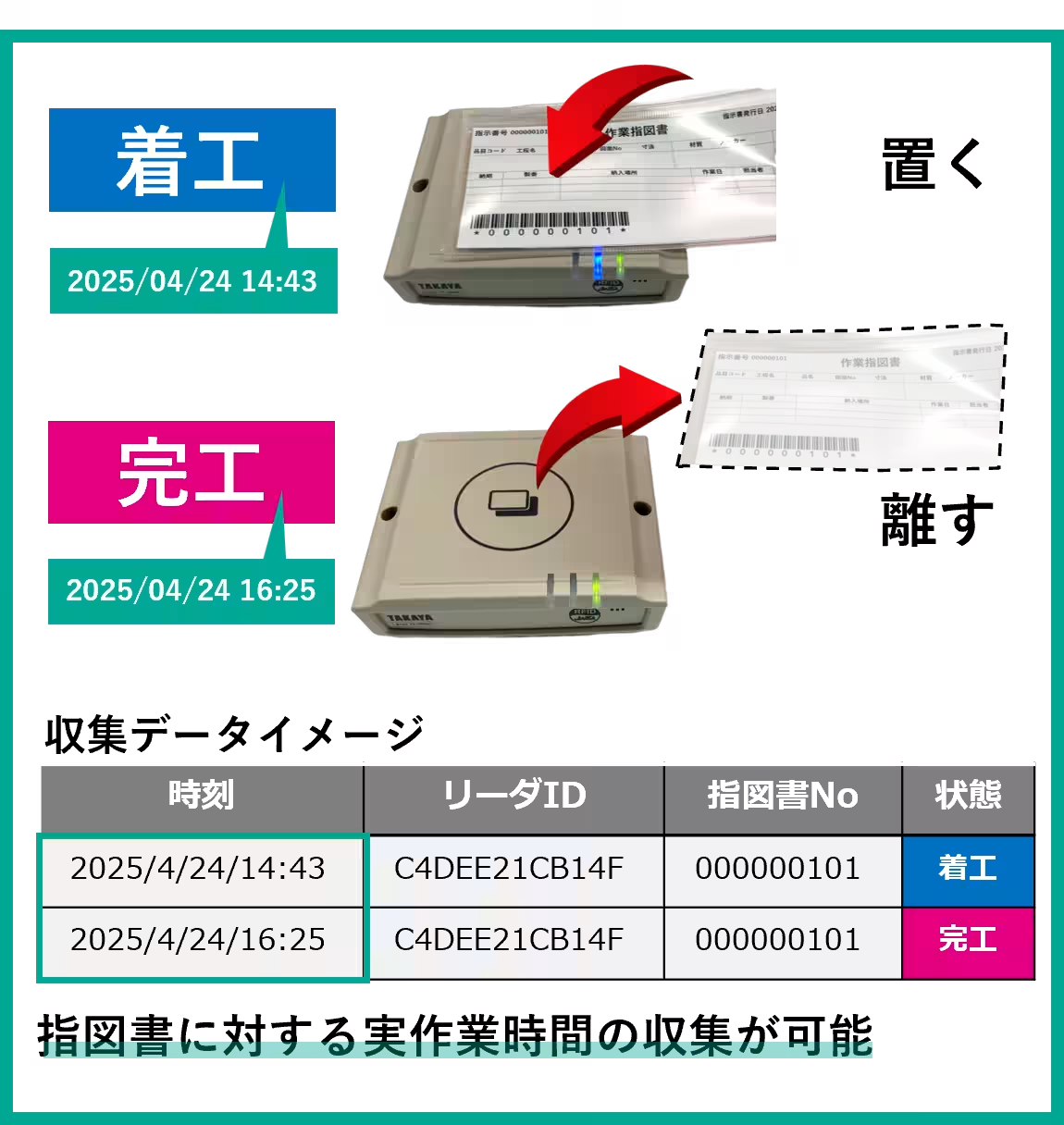

To illustrate the capabilities of the RFID encoding software, Takaya provides an example of how operational efficiency can be enhanced. By replacing barcode data in work orders with RFID systems, businesses can streamline the process of gathering actual work times through simple RFID tag handling. The steps include:

1. Attach the RFID Tag: Place the RFID tag on the back of the work order.

2. Write to the RFID Tag: Scan the barcode (work order number) and transfer that data onto the RFID tag.

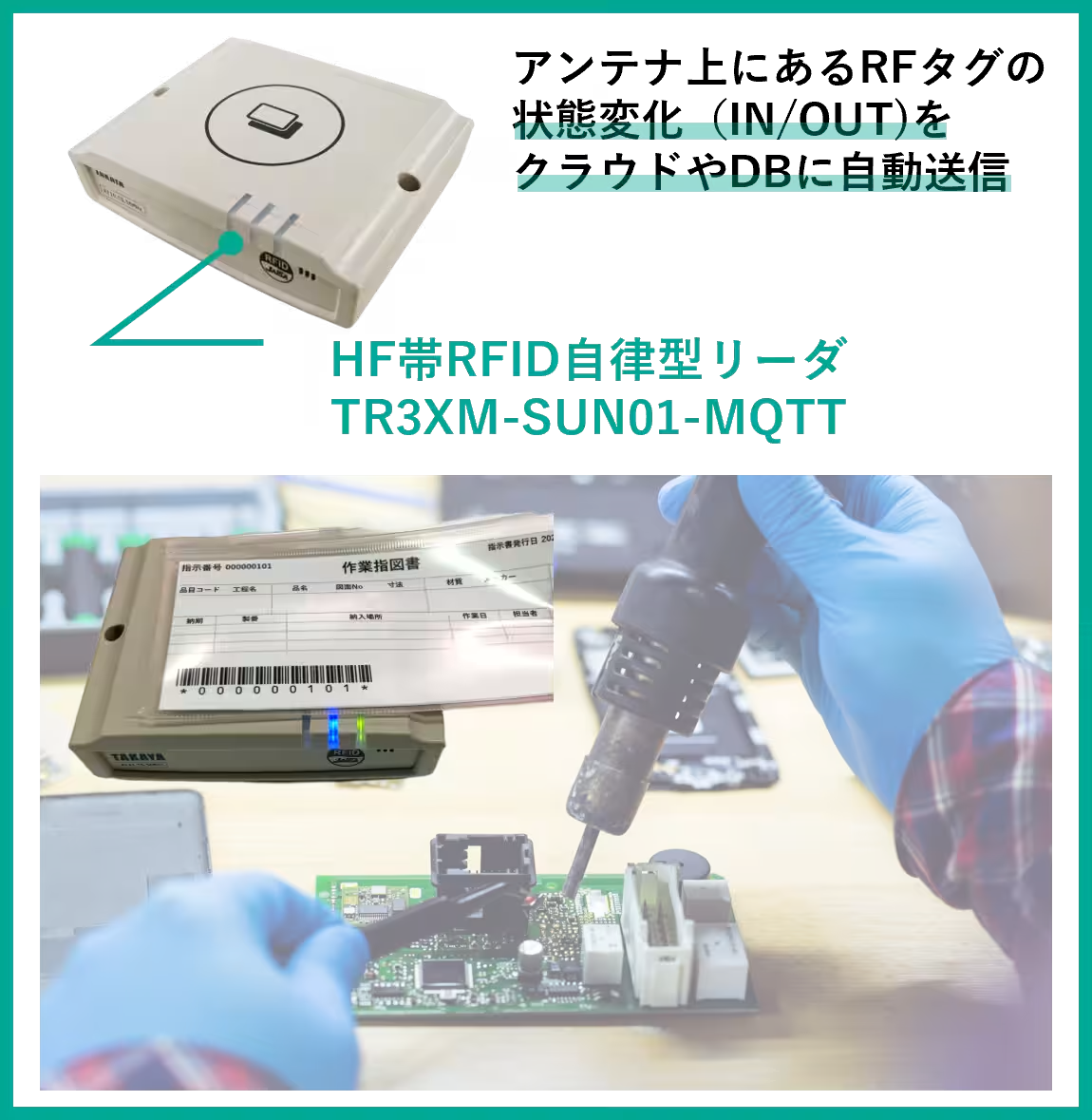

3. Install Readers: Position readers at various phases of production to link them with operational processes.

4. Collect Work Performance Data: At the start and end of tasks, merely place or remove the work order from the RFID reader to capture precise work intervals without fuss.

This system not only provides a more accurate collection of working times but also improves cost calculation precision and optimal staffing configurations. Overall, this leads to enhanced operational efficiencies and significant cost savings.

Technical Requirements

For successful implementation, certain hardware is necessary along with Takaya's software:

- - Hardware: HF Autonomous Reader (MQTT Compatible)

- - System: RFID Operational Performance Collection System

Software Download

- - Software:

- - Manual: Available in the software documentation.

About Takaya Inc.

Founded in 1894, Takaya started as a textile manufacturer and evolved into electronics. Since establishing its electronics division in 1966, it has engaged in various electronics sectors, including contract production (EMS), manufacturing and selling RFID technologies, security devices, and offering IT consulting.

- - Company Title: Takaya Inc.

- - CEO: Ryuji Okamoto

- - Headquarters: 661-1 Ibarmachi, Ibara City, Okayama Prefecture, Japan

- - Established: September 2, 1918

- - Capital: 100 million yen

Mission and Vision

Takaya aims to innovate and provide solutions in RFID and electronic sectors while focusing on quality assurance and customer satisfaction. Visit their official site or check the RFID product site for more information.

Topics Business Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.