The Release of the Second Edition of the Smart Manufacturing Guidelines Supporting DX in Manufacturing Industry

Introduction

In a bid to enhance digital transformation (DX) within the manufacturing sector, the Japan Management Association Consulting (JMAC) has publicly announced the second edition of its Smart Manufacturing Guidelines (SMDG). This initiative is supported by the New Energy and Industrial Technology Development Organization (NEDO) and is significant as it addresses a wide range of challenges manufacturers face today.

Launched Research Project

Commissioned by NEDO, JMAC's project focuses on enhancing dynamic capabilities in manufacturing through the effective use of advanced technologies such as 5G. The research, conducted during the 2023-2024 fiscal year, emphasizes optimizing the entire manufacturing process through digital technologies, encompassing design, production management, manufacturing, and sales/services.

Continuous Improvement

The guidelines build upon the foundation laid by the first version released in June 2024, with a goal to validate the practical application by manufacturing enterprises and discussions with IT vendors by March 2025. Specifically, the study sought to determine whether manufacturers could effectively utilize these guidelines and derive actionable insights, particularly from the reference material that outlines structural building methods based on the level of implementation, especially regarding solution categories.

Enhancements in the Second Edition

The second edition of the Smart Manufacturing Guidelines incorporates several key improvements aimed at facilitating better application:

1. New Relevant Information: The main document now includes supplementary information regarding the chain concept and various initiatives promoted by the Ministry of Economy, Trade and Industry (METI) to enhance DX efforts.

2. Refined Reference Materials: Adjustments were made to the mapping for transformational challenges categorized by environmental change, correcting previous numbering inconsistencies.

3. Aligned Solution Categories: The determination was made on whether the various solution categories related to transformational challenges could align better with actual IT solutions provided by vendors, leading to specific adjustments and additions.

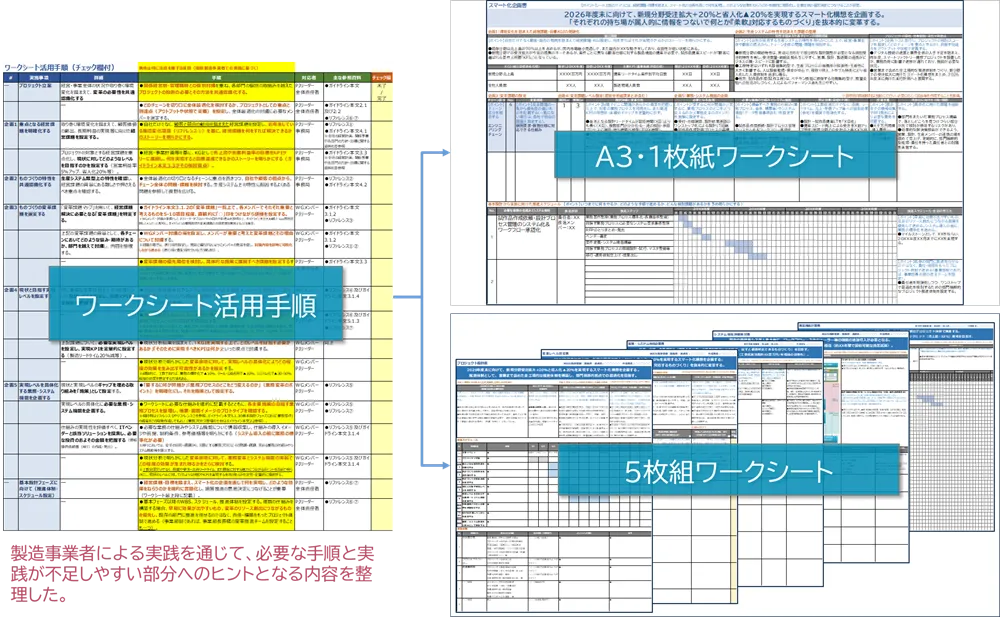

4. Practical Worksheets: New worksheets have been introduced, offering structured procedures that enable project leaders and teams to clearly understand their objectives and necessary outputs, thus facilitating smoother project management. These worksheets also include strategies for common pitfalls faced by manufacturing enterprises.

5. Overview of Practical Worksheets: An explanation of practical worksheets and their usage instructions is now provided.

Video Resources for Understanding the Guidelines

To aid in the effective utilization of the guidelines, JMAC has produced two instructional videos published in February 2025:

- - 5-Minute Overview of SMDG: Offers a concise explanation of the Smart Manufacturing Guidelines.

- - 30-Minute Usage Guide: Provides deeper insights into how to use the guidelines effectively.

Community Engagement

JMAC expresses deep gratitude to manufacturing and IT services stakeholders who provided valuable insights and advice during the revision process. Such collaboration has been vital for ensuring the guidelines meet the practical needs of the industry.

Reference Material

For further details, interested parties can visit the NEDO download site for the Smart Manufacturing Guidelines here.

Additionally, an overview of the first edition of the guidelines can be accessed through JMAC's news release here.

Conclusion

The second edition of the Smart Manufacturing Guidelines marks a significant milestone in Japan's manufacturing digital transformation journey, promising to provide manufacturers with the tools and frameworks required to thrive in an increasingly digital landscape. With continuous adaptation and improvement, these guidelines ensure that the manufacturing sector can respond dynamically to the ever-evolving demands of the market.

About JMAC

Japan Management Association Consulting (JMAC), established in 1980, offers comprehensive consulting services across various domains such as strategy, marketing, supply chain, and IT business. With around 370 employees and a commitment to advancing management practices in the manufacturing sector, JMAC seeks to foster innovation and efficiency in Japanese manufacturing.

For more information, please visit JMAC's official site.

Topics Business Technology)

【About Using Articles】

You can freely use the title and article content by linking to the page where the article is posted.

※ Images cannot be used.

【About Links】

Links are free to use.